Quick Answer (30 seconds)

Designing a Hurricane Monitor PCB requires adhering to strict reliability standards to survive Category 5 wind speeds, rapid pressure drops, and saltwater immersion. Unlike standard consumer electronics, these boards function as critical safety infrastructure where failure results in data gaps during life-threatening events.

- Standard Compliance: Must meet IPC-6012 Class 3 requirements for high reliability and continuous performance in harsh environments.

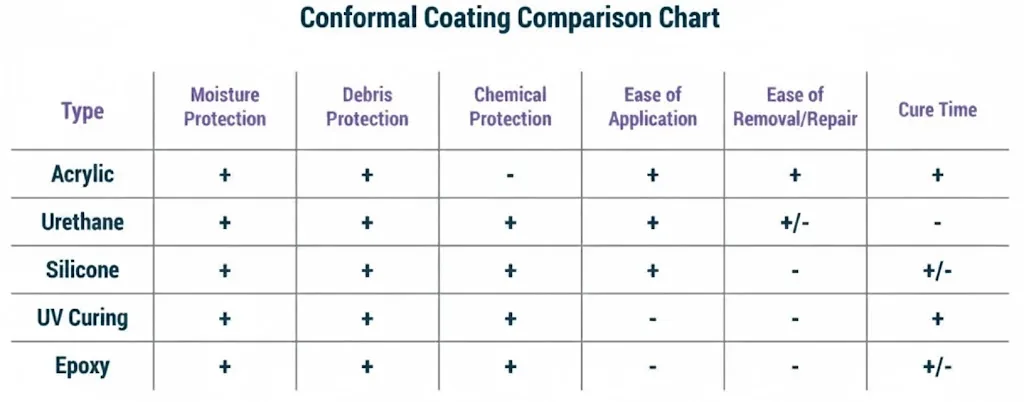

- Moisture Protection: Conformal coating is non-negotiable; Parylene (Type XY) or high-grade Acrylic is required to prevent salt spray corrosion.

- Material Selection: Use High-Tg FR4 (Tg > 170°C) or RF substrates (Rogers/Taconic) to maintain signal integrity during rapid thermal cycling.

- Vibration Resistance: Components must be anchored with underfill or staking compounds to withstand G-forces typical of dropsondes or turbulent buoy movement.

- Signal Integrity: Controlled impedance is critical for telemetry modules transmitting data to satellites or ground stations.

- Validation: Mandatory environmental stress screening (ESS), including thermal shock and vibration testing, before deployment.

When Hurricane Monitor PCB applies (and when it doesn’t)

Understanding the operational environment is the first step in selecting the right manufacturing process for weather monitoring electronics.

When to use Hurricane Monitor PCB standards:

- Aerial Dropsondes: Devices deployed from aircraft into storm eyes requiring survival through extreme turbulence and impact.

- Oceanic Weather Buoys: Systems exposed to constant salt fog, wave impact, and UV radiation.

- Coastal Telemetry Stations: Fixed installations in high-wind zones requiring uninterrupted power and data transmission.

- Emergency Response Drones: UAVs specifically designed to fly into or near severe weather systems for data collection.

- Satellite Uplink Modules: High-frequency communication boards that must remain stable despite rapid temperature changes.

When standard PCBs are sufficient (Do not use Hurricane specs):

- Indoor Home Weather Stations: Consumer-grade devices protected from direct element exposure.

- General Climate Monitor PCB: For benign agricultural environments where extreme vibration and salt spray are not factors.

- Educational Kits: Basic weather sensors used in classrooms or controlled lab settings.

- Short-range Bluetooth Trackers: Unless deployed in a storm zone, standard FR4 and HASL finishes are usually adequate.

Rules & specifications

To ensure a Hurricane Monitor PCB survives deployment, engineers must define specific parameters in the fabrication notes. APTPCB (APTPCB PCB Factory) recommends the following specifications to minimize field failures.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Base Material | High-Tg FR4 (>170°C) or Rogers 4000 series | Prevents delamination during thermal shock and maintains RF stability. | Check material datasheet & IPC-4101 spec. | Board warpage or signal drift during temp spikes. |

| Surface Finish | ENIG or ENEPIG | Excellent corrosion resistance and flat surface for fine-pitch components. | X-Ray Fluorescence (XRF) measurement. | HASL may oxidize in salt air; OSP degrades quickly. |

| Conformal Coating | Parylene (Type XY) or Acrylic (AR) | Provides a moisture and dielectric barrier against salt fog. | UV inspection (if tracer added) or thickness gauge. | Dendritic growth and short circuits within hours. |

| Copper Weight | 1 oz minimum (Outer), 2 oz (Power) | Mechanical strength and current handling during power surges. | Microsection analysis. | Trace cracking under vibration or high current heat. |

| Via Protection | IPC-4761 Type VII (Filled & Capped) | Prevents entrapment of corrosive chemicals and moisture in vias. | Visual inspection & cross-section. | Vias corrode from inside out; long-term open circuits. |

| Solder Mask | LPI (Liquid Photoimageable), Green/Blue | Primary insulation layer; must adhere perfectly to prevent peeling. | Tape test (IPC-TM-650). | Mask peeling allows moisture ingress to copper. |

| Ionic Cleanliness | < 1.56 µg/NaCl eq/cm² | Salt residue accelerates corrosion under humidity. | ROSE testing (Resistivity of Solvent Extract). | Rapid electrochemical migration (ECM) failure. |

| Component Staking | Epoxy or Silicone on large parts | Prevents heavy components (caps, inductors) from shearing off. | Visual inspection / Pull test. | Components detach during launch or turbulence. |

| Impedance Control | 50Ω ± 5% (Single), 100Ω ± 10% (Diff) | Ensures accurate data transmission to satellites/receivers. | TDR (Time Domain Reflectometry). | Data packet loss; inability to transmit storm data. |

| Drill Wander | ± 3 mils (0.075mm) max | Critical for maintaining annular rings in dense layouts. | X-Ray alignment check. | Breakout leads to open circuits under stress. |

Implementation steps

Building a ruggedized PCB involves more than just layout; the manufacturing process flow must account for environmental hardening.

Define Environmental Profile:

- Action: Determine the maximum wind speed (vibration), altitude (pressure), and salinity exposure.

- Parameter: e.g., Category 5 (157+ mph), 0-100% RH.

- Check: Does the BOM support -40°C to +85°C operation?

Select Laminate & Stackup:

- Action: Choose a low-CTE material to match component expansion rates.

- Parameter: Tg > 170°C, Td > 340°C.

- Check: Verify dielectric constant (Dk) stability for RF frequencies.

Layout for Vibration:

- Action: Place heavy components near mounting holes; avoid placing sensitive BGAs in the center of the board (max flex point).

- Parameter: Keep-out zones > 5mm around mounting points.

- Check: Perform Vibration Simulation (FEA) if possible.

Fabrication with Advanced PCB Manufacturing:

- Action: Execute drilling and plating with Class 3 tolerances.

- Parameter: Min annular ring 2 mil (external).

- Check: 100% Electrical Test (Flying Probe) required.

Assembly & Soldering:

- Action: Use water-soluble flux and ensure thorough cleaning to remove residues.

- Parameter: Reflow profile optimized for lead-free solder (SAC305).

- Check: Automated Optical Inspection (AOI) for solder joint quality.

Underfill & Staking:

- Action: Apply adhesive to corners of BGAs and bases of electrolytic capacitors.

- Parameter: Cure time/temp per adhesive spec.

- Check: Visual verification of fillet height.

Conformal Coating Application:

- Action: Apply PCB Conformal Coating to the entire assembly, masking connectors.

- Parameter: Thickness 25-75 microns (depending on material).

- Check: UV light inspection to ensure full coverage without bubbles.

Final Environmental Screening:

- Action: Subject the board to a burn-in cycle.

- Parameter: 24 hours at varying temps or vibration sweep.

- Check: Functional test pass/fail after screening.

Failure modes & troubleshooting

Even with robust design, failures can occur. Here is how to diagnose issues specific to Hurricane Monitor PCB units.

1. Intermittent Signal Loss during Storms

- Cause: Micro-cracks in solder joints due to high-frequency vibration or board flexing.

- Check: Microsection analysis of the failing joint; look for "pad cratering."

- Fix: Switch to a more flexible resin system or increase pad size.

- Prevention: Add more mounting holes to stiffen the board; use underfill on BGAs.

2. Rapid Corrosion (Green/White Residue)

- Cause: Salt spray ingress through pinholes in the conformal coating or inadequate cleaning before coating.

- Check: Inspect under UV light for coating voids; test for ionic contamination.

- Fix: Clean assembly thoroughly; re-apply thicker coating or switch to Parylene.

- Prevention: Implement strict ionic cleanliness limits (<1.0 µg/NaCl) before coating.

3. RF Telemetry Drift

- Cause: Moisture absorption by the PCB substrate changes the Dielectric Constant (Dk).

- Check: Measure impedance in high-humidity chamber vs. dry.

- Fix: Use low-hygroscopic materials like Rogers or PTFE-based laminates.

- Prevention: Seal board edges; use High Frequency PCB materials designed for moisture resistance.

4. Power Failure at Low Altitude (Dropsondes)

- Cause: Condensation shorting power rails as the device drops from cold high altitude to warm, humid sea level.

- Check: Look for arc tracks between high-voltage traces.

- Fix: Increase creepage/clearance distances; apply potting compound.

- Prevention: Design layout with wider spacing for high-potential nets.

5. Mechanical Component Detachment

- Cause: G-force impact upon water landing or deployment shock.

- Check: Visual inspection of heavy components (batteries, large caps).

- Fix: Use mechanical brackets or RTV silicone staking.

- Prevention: Analyze component mass vs. solder pad strength during design.

6. Via Barrel Cracking

- Cause: Z-axis expansion of the PCB during thermal cycling exceeds copper ductility.

- Check: Cross-section analysis showing open circuits in vias.

- Fix: Use materials with lower Z-axis CTE; increase copper plating thickness in holes.

- Prevention: Specify IPC Class 3 plating (average 25µm).

Design decisions

Successful deployment relies on making the right trade-offs early in the design phase.

Material Selection: FR4 vs. PTFE While standard FR4 is cost-effective, it absorbs moisture (up to 0.25%), which ruins RF performance in hurricane conditions. For any Hurricane Monitor PCB handling signals above 1GHz, APTPCB recommends PTFE or ceramic-filled hydrocarbon laminates (e.g., Rogers 4350B) which have moisture absorption as low as 0.04%.

Rigid vs. Rigid-Flex Many sensors, especially in dropsondes, must fit into cylindrical tubes. A Rigid-Flex PCB design eliminates connectors—which are common failure points in high-vibration environments—and allows the board to fold into compact shapes. This improves reliability by reducing the total part count and solder joints.

Thermal Management Hurricanes are not always cold; the electronics inside a sealed enclosure can overheat. Using Heavy Copper or metal-core designs helps dissipate heat from power amplifiers without needing bulky heatsinks that add dangerous weight to aerial sensors.

FAQ

Q: What is the typical lead time for a Hurricane Monitor PCB? A: Standard lead time is 10-15 days for fabrication and assembly.

- Quick-turn options (3-5 days) are available for prototyping.

- Specialty materials (Rogers, Arlon) may add 1-2 weeks if not in stock.

Q: Can I use standard FR4 for a weather buoy PCB? A: Only if the buoy is sealed perfectly and the frequency is low.

- For high reliability, High-Tg FR4 is the minimum requirement.

- Standard FR4 may delaminate under constant thermal cycling and moisture.

Q: How does this differ from a Drought Monitor PCB? A: A Drought Monitor PCB focuses on high-temperature survival and dust protection.

- Hurricane monitors prioritize vibration, impact, and moisture/salt protection.

- Drought monitors rarely face the G-forces of a storm environment.

Q: Is Parylene coating necessary? A: For direct exposure to sea air, yes.

- Parylene provides the best pinhole-free coverage.

- Acrylic or Silicone is acceptable for sealed enclosures with desiccants.

Q: What testing data do I need to provide for a quote? A: Provide your environmental requirements (Temp, Vibration, IP rating).

- Specify IPC Class (Class 2 or 3).

- Include impedance requirements for RF lines.

Q: Does APTPCB handle the component sourcing for these boards? A: Yes, we offer full turnkey services.

- We source automotive or industrial-grade components.

- We verify component lifecycle to avoid obsolete parts in critical designs.

Q: How do you prevent salt spray corrosion on connectors? A: We recommend gold-plated contacts (Hard Gold) and protective caps.

- During assembly, we mask connectors before conformal coating.

- Dielectric grease can be applied to contacts post-assembly.

Q: Can you manufacture Compaction Monitor PCBs or Vibration Monitor PCBs? A: Yes, the manufacturing requirements are very similar.

- Both require robust soldering and vibration-resistant layouts.

- We apply the same ruggedization techniques to these industrial sensors.

Q: What is the cost difference for IPC Class 3 vs Class 2? A: Class 3 is typically 15-25% more expensive.

- Requires tighter manufacturing tolerances and more frequent inspection.

- Mandatory cross-sectioning and coupon testing add to the cost.

Q: Do you support design reviews for DFM? A: Yes, every order undergoes a detailed DFM review.

- We check for acid traps, slivers, and annular ring violations.

- We suggest stackup optimizations for impedance and cost.

Related pages & tools

- PCB Conformal Coating Services

- High Frequency PCB Manufacturing

- Rigid-Flex PCB Capabilities

- Aerospace & Defense PCB Solutions

- Advanced PCB Manufacturing

Glossary (key terms)

| Term | Definition | Relevance to Hurricane Monitor PCB |

|---|---|---|

| IPC-6012 Class 3 | Performance class for high-reliability electronic products. | Required for equipment where downtime is not tolerable (e.g., storm tracking). |

| Conformal Coating | A protective chemical coating applied to the PCBA. | Essential barrier against salt spray, humidity, and fungus. |

| Tg (Glass Transition Temp) | The temperature at which the PCB resin turns soft. | High Tg prevents barrel cracks during thermal shock. |

| CTE (Coeff. of Thermal Expansion) | How much the material expands with heat. | Mismatched CTE causes solder joint fatigue; critical in varying temps. |

| Dropsonde | A weather reconnaissance device dropped from aircraft. | Requires extreme impact and vibration resistance. |

| Salt Fog Test | A standardized corrosion test (ASTM B117). | Validates the effectiveness of the enclosure and coating. |

| Impedance Control | Maintaining specific resistance in signal traces. | Vital for RF telemetry data integrity. |

| ENIG | Electroless Nickel Immersion Gold surface finish. | Provides flat surface and corrosion resistance for pads. |

| Vias-in-Pad | Placing a via directly under a component pad. | Saves space but requires plugging/capping to prevent solder theft. |

| ESS (Environmental Stress Screening) | Testing products under stress to force latent defects. | Filters out weak units before deployment into a storm. |

Request a quote

Ready to build reliable Hurricane Monitor PCBs? APTPCB provides a comprehensive DFM review to ensure your design meets Class 3 specs and withstands the harshest elements.

Please prepare the following for an accurate quote:

- Gerber Files: RS-274X format.

- Fabrication Drawing: Specify IPC Class, material (Tg), and color.

- Stackup: Layer count and impedance requirements.

- BOM: For turnkey assembly (include manufacturer part numbers).

- Coating Specs: Type of conformal coating required.

- Volume: Prototype quantity vs. mass production estimates.

Conclusion

A Hurricane Monitor PCB is the backbone of critical weather infrastructure, demanding zero-failure performance in the world's most hostile environments. By strictly adhering to IPC Class 3 standards, utilizing advanced materials like Rogers or High-Tg FR4, and applying robust conformal coatings, engineers can ensure data continuity when it matters most. Whether you are designing dropsondes, buoys, or coastal radar systems, prioritizing reliability in the manufacturing phase is the only way to guarantee mission success.