HVAC system PCB assemblies control heating, ventilation, and air conditioning implementing temperature sensing, blower motor control, compressor management, and user interface supporting automotive climate control, residential thermostats, and commercial building systems requiring precise temperature regulation (±0.5°C), energy-efficient operation, and reliable performance through 10-15 year operational lifecycles with millions of on-off cycles.

At APTPCB, we deliver HVAC assembly services with motor control expertise, sensor integration, and user interface implementation supporting turnkey assembly across automotive and building automation applications.

Implementing Precision Temperature Control

HVAC systems require accurate temperature measurement (<0.5°C), humidity sensing, and multi-zone control executing PID algorithms maintaining comfortable conditions while optimizing energy efficiency. Temperature control challenges include sensor placement optimization, managing thermal lag, and preventing temperature oscillation. Inadequate control causes uncomfortable temperature swings, excessive energy consumption, or zone imbalances — significantly impacting comfort and operating costs.

At APTPCB, our assembly implements precision climate control achieving comfortable conditions with optimal efficiency.

Climate Control Implementation

- Precision Sensors: NTC thermistors or digital temperature sensors with ±0.5°C accuracy and PCB conformal coating protection.

- PID Control Algorithms: Tuned control loops maintaining setpoint while minimizing overshoot and settling time.

- Multi-Zone Management: Independent zone control optimizing comfort while reducing energy waste in unoccupied areas.

- Humidity Control: Integrated humidity sensing enabling dehumidification and optimal comfort management.

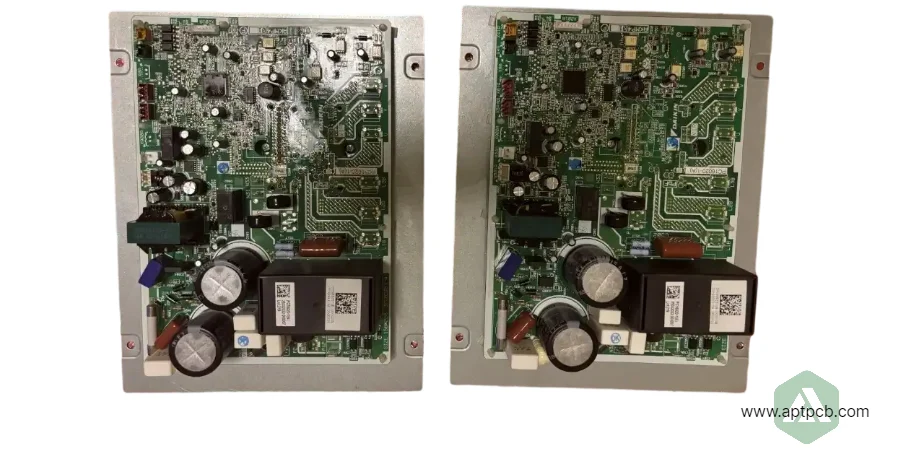

Managing Blower and Compressor Control

HVAC systems drive blower motors (50-500W) and compressor systems requiring motor speed control, soft start, and protection circuits. Motor control challenges include minimizing acoustic noise, managing inrush current, and providing thermal protection. Inadequate motor control causes excessive noise, frequent compressor cycling, or premature motor failures — significantly impacting comfort and system reliability.

At APTPCB, our manufacturing supports efficient motor control achieving quiet operation and long motor life.

Motor Control Implementation

- Variable Speed Control: PWM or triac-based blower control providing continuous speed adjustment optimizing airflow and efficiency with special PCB manufacturing capability.

- Soft Start Circuits: Gradual voltage ramp reducing inrush current and mechanical stress on compressor startup.

- Thermal Protection: Motor temperature monitoring and current limiting preventing overheating damage.

- Noise Optimization: PWM frequency selection and filtering minimizing audible motor noise.

Integrating User Interface and Connectivity

Modern HVAC systems provide touchscreen displays, smartphone control, and voice assistant integration requiring display drivers, wireless connectivity, and user-friendly interfaces. Interface challenges include outdoor visibility, responsive touch operation, and reliable wireless connectivity. Inadequate interface implementation frustrates users, limits remote control capability, or causes connectivity issues — significantly impacting user satisfaction and smart home integration.

At APTPCB, our assembly supports advanced user interfaces achieving intuitive control and smart connectivity.

Interface Implementation

- Display Integration: LCD or OLED displays with touch control providing intuitive temperature adjustment and scheduling.

- WiFi/Bluetooth Connectivity: Smartphone apps enabling remote control, scheduling, and energy monitoring.

- Voice Assistant Integration: Alexa, Google Home, Siri compatibility supporting hands-free control.

- Occupancy Detection: Motion or ultrasonic sensors enabling automatic operation based on room occupancy.

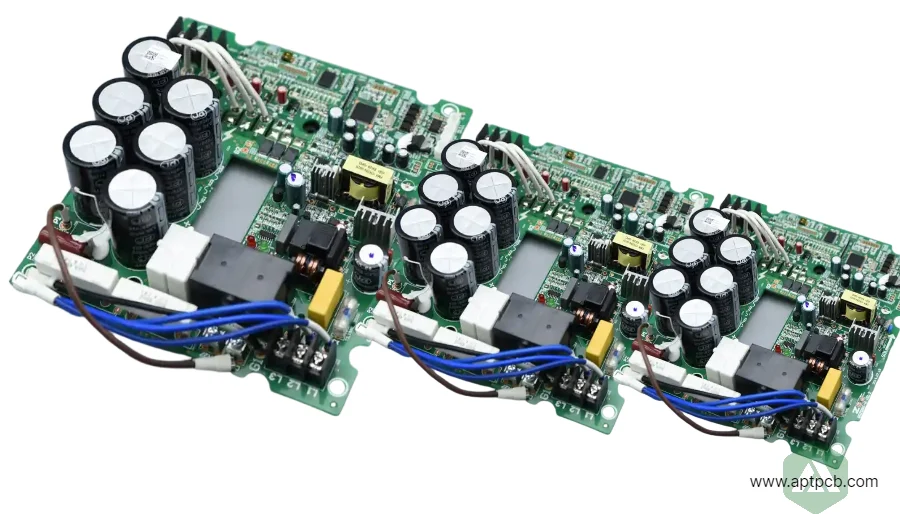

Ensuring Energy Efficiency and Compliance

HVAC systems consume significant building energy requiring efficient operation, smart scheduling, and energy monitoring meeting Energy Star and regulatory requirements. Energy challenges include optimizing compressor cycling, managing fan speeds, and adapting to occupancy patterns. Inadequate efficiency causes high operating costs, fails energy certifications, or wastes resources — significantly impacting total cost of ownership and environmental impact.

At APTPCB, our manufacturing supports energy-efficient designs meeting regulatory requirements and minimizing operating costs.

Energy Efficiency Implementation

- Inverter Compressor Control: Variable speed compressor operation reducing energy 30-50% versus on-off cycling.

- Smart Scheduling: Learning algorithms optimizing operation based on occupancy patterns and weather forecasts.

- Energy Monitoring: Real-time consumption tracking identifying efficiency opportunities and quantifying energy savings.

- Compliance Testing: Energy Star certification and regulatory compliance validation supporting market access.

Through energy-efficient design and smart control coordinated with functional testing validation, APTPCB enables HVAC systems achieving optimal comfort with minimal energy consumption.

Supporting Diverse Applications

HVAC electronics serve automotive cabin climate, residential thermostats, and commercial building systems requiring application-specific optimizations in form factor, capacity, and features. Application diversity challenges include managing varying power levels, environmental conditions, and integration requirements.

At APTPCB, we support diverse HVAC applications with flexible manufacturing.

Application Support

Automotive HVAC

- Compact packaging fitting dashboard or underhood installations.

- Automotive qualification surviving -40 to +85°C environments.

- CAN bus integration with vehicle climate control systems.

Residential and Commercial

- Multiple zone support for whole-building climate management.

- Smart home integration with building automation systems.

- Extended reliability supporting 15+ year service life.

Through application-optimized designs and flexible manufacturing coordinated with quality inspection processes, APTPCB enables HVAC solutions across automotive, residential, and commercial markets.