Infotainment system PCB assemblies integrate multi-core processors, high-resolution display controllers, audio DSPs, wireless connectivity (WiFi, Bluetooth, cellular), and navigation systems supporting touchscreen interfaces, voice control, smartphone integration (CarPlay, Android Auto), and connected services requiring automotive qualification (-40 to +85°C), functional safety compliance, and 15+ year reliability across passenger vehicles, commercial trucks, and premium automotive platforms demanding seamless user experience through millions of ignition cycles.

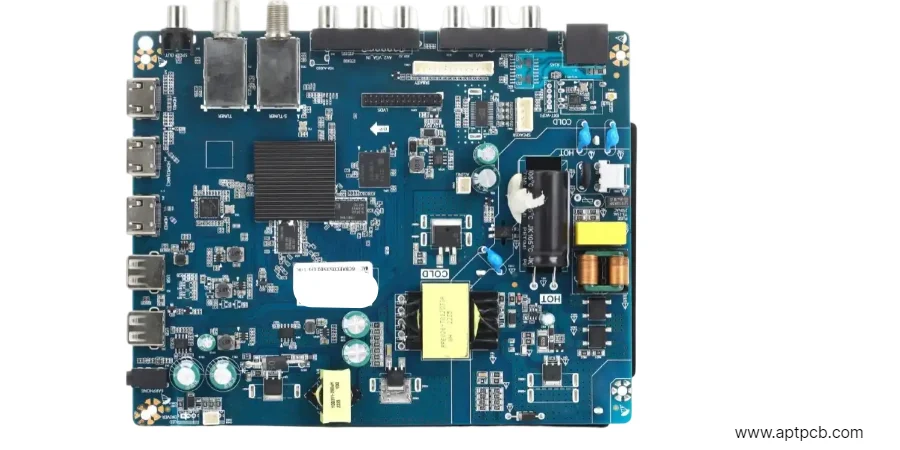

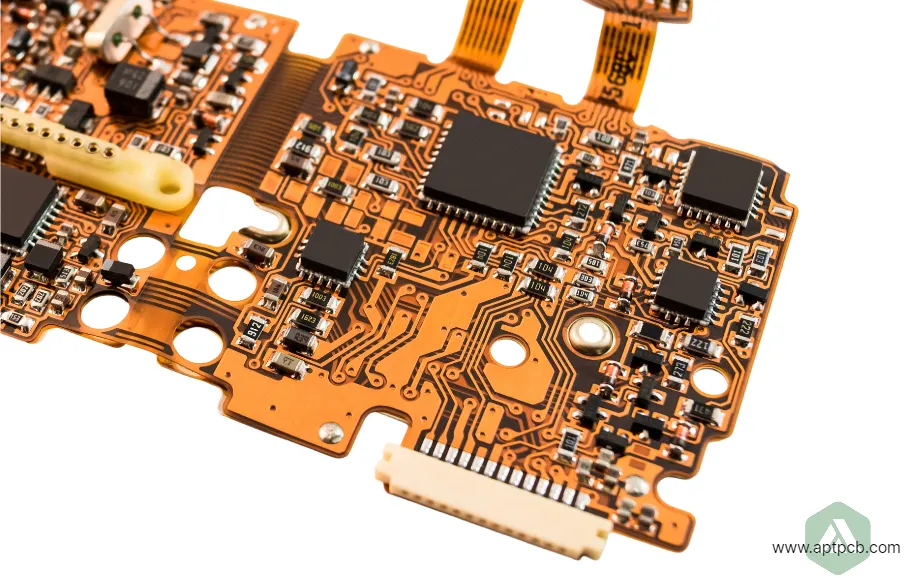

At APTPCB, we deliver specialized infotainment assembly services implementing high-performance computing, multi-display support, and audio processing with box build assembly capabilities supporting entry-level through premium infotainment systems.

Implementing High-Performance Display Processing

Modern infotainment systems drive 8-12 inch touchscreens at 1920x1080 or higher resolutions plus additional displays (instrument cluster, rear entertainment) requiring powerful GPU processing, high-bandwidth LVDS or eDP interfaces, and real-time 3D rendering for navigation and UI. Display challenges include maintaining 60fps smooth animations, preventing screen tearing during updates, and ensuring readability under direct sunlight. Inadequate display implementation causes laggy user interface frustrating users, slow map rendering affecting navigation usability, or poor outdoor visibility limiting functionality — significantly impacting perceived quality and customer satisfaction in automotive markets where infotainment performance influences purchase decisions.

At APTPCB, our assembly implements validated display architectures achieving premium visual performance and responsiveness.

Display Processing Implementation

- High-Performance SoCs: Automotive-qualified processors (NXP i.MX, Qualcomm Snapdragon Auto, Renesas R-Car) with dedicated GPU supporting 3D graphics with testing quality validation.

- Multi-Display Support: Simultaneous output to primary touchscreen, instrument cluster, and rear seat displays maintaining synchronized content and independent control.

- High-Brightness Interface: Display panel control supporting 800-1200 nits brightness enabling outdoor readability with automatic brightness adjustment based on ambient light.

- Touch Controller Integration: Capacitive or resistive touch controllers with glove mode and wet finger operation supporting automotive environments.

- Video Input Processing: Camera inputs for rear view, surround view, and dashcam integration requiring low-latency video processing <100ms.

- Display Calibration: Color accuracy and uniformity calibration ensuring consistent appearance across production units and maintaining quality through temperature variations.

Premium Display Experience

Through high-performance processing and comprehensive display optimization coordinated with functional testing validation, APTPCB enables infotainment systems achieving smartphone-like responsiveness and visual quality.

Integrating Audio Processing and Amplification

Automotive audio systems process multiple input sources (radio, streaming, navigation, phone), apply equalization and sound processing, and drive 4-16 speaker systems requiring low-noise analog design, high-power amplification, and automotive EMC compliance. Audio challenges include eliminating alternator whine and engine noise interference, achieving wide dynamic range supporting both quiet voice and loud music, and managing thermal dissipation from multi-channel amplifiers. Inadequate audio implementation causes background noise degrading listening experience, distortion at high volume levels, or channel imbalance affecting sound staging — significantly impacting perceived audio quality and customer satisfaction especially in premium vehicles where audio performance is key differentiator.

At APTPCB, our manufacturing supports premium audio integration achieving concert-quality sound reproduction.

Audio Processing Implementation

- Multi-Channel DSP: Dedicated audio processors applying equalization, crossover, bass management, and sound field processing supporting premium audio brands (Bose, Harman Kardon, B&O) through quality system manufacturing.

- High-SNR Audio Paths: Low-noise amplifier design, grounded shielding, and filtered power achieving >100dB signal-to-noise ratio eliminating audible noise floor.

- Class-D Amplification: Efficient switching amplifiers delivering 25-100W per channel with >85% efficiency minimizing heat dissipation while maintaining audio quality.

- Automotive EMC Compliance: Filtered outputs, shielded cables, and proper grounding preventing interference from alternator, ignition, and motor noise.

- Acoustic Tuning: Digital signal processing compensating for vehicle acoustics achieving balanced frequency response across seating positions.

- Thermal Management: Heat sink integration and thermal monitoring preventing amplifier overheating during sustained high-volume operation in hot climates.

Premium Audio Quality

By implementing high-performance audio processing, low-noise design, and comprehensive acoustic optimization supported by automotive manufacturing expertise, APTPCB enables infotainment systems delivering exceptional audio quality across entry-level through luxury vehicle segments.

Supporting Wireless Connectivity and Smartphone Integration

Modern infotainment demands seamless smartphone integration through CarPlay, Android Auto, and wireless mirroring plus built-in WiFi, Bluetooth, and optional cellular connectivity enabling streaming services, over-the-air updates, and connected services. Connectivity challenges include maintaining stable Bluetooth audio despite EMI-rich automotive environment, achieving low-latency wireless mirroring <100ms, and managing cellular data for navigation and streaming. Inadequate connectivity implementation causes frequent Bluetooth dropouts frustrating users, laggy wireless CarPlay affecting usability, or unreliable cellular connection limiting connected features — significantly impacting user experience and competitive positioning as connectivity becomes essential expectation.

At APTPCB, our assembly integrates comprehensive wireless connectivity achieving reliable smartphone integration and connected services.

Wireless Integration Implementation

- CarPlay/Android Auto Support: Wired and wireless connectivity supporting iOS and Android smartphone integration with certified implementation ensuring compatibility and NPI assembly validation.

- Multi-Radio Coexistence: WiFi 5/6, Bluetooth 5.0+, cellular (LTE/5G), and AM/FM radio with proper isolation and filtering preventing mutual interference.

- High-Performance WiFi: Dual-band WiFi supporting fast OTA updates and streaming content with automotive-grade modules surviving temperature extremes.

- Bluetooth Audio Quality: aptX or AAC codec support delivering high-quality wireless audio from smartphones with stable connection despite electrical noise.

- Cellular Connectivity: Embedded LTE/5G modem with eSIM supporting connected navigation, streaming services, and remote vehicle monitoring.

- Antenna Integration: Multi-antenna system optimizing performance across frequency bands while fitting within vehicle design constraints.

Seamless Connected Experience

Through comprehensive wireless integration, certified smartphone connectivity, and robust implementation validated through automotive testing, APTPCB enables infotainment systems delivering seamless smartphone integration and connected services meeting consumer expectations.

Ensuring Automotive Qualification and Reliability

Infotainment electronics operate in harsh automotive environments from -40°C Arctic cold through +85°C dashboard temperatures plus vibration, humidity, and electrical transients requiring AEC-Q qualified components, extensive environmental testing, and validated long-term reliability. Automotive reliability challenges include surviving 3000+ temperature cycles, withstanding 24V load dump transients, and maintaining performance despite years of UV and thermal exposure. Inadequate qualification causes premature failures from component degradation, system resets from voltage transients, or display failures from thermal stress — significantly impacting warranty costs, brand reputation, and customer satisfaction requiring expensive field repairs or replacements.

At APTPCB, our manufacturing implements automotive-qualified processes ensuring 15+ year operational reliability.

Automotive Qualification Implementation

- AEC-Q Component Selection: Complete automotive supply chain with qualified semiconductors, displays, and passives surviving automotive environmental stresses through mass production component qualification.

- Extended Temperature Testing: Validation from -40 to +85°C operational and -50 to +105°C storage ensuring reliable performance across climate extremes.

- Vibration and Mechanical Testing: Random vibration per automotive standards validating component attachment and preventing solder joint fatigue during vehicle operation.

- Transient Protection: Load dump, reverse polarity, and ESD protection circuits preventing damage from automotive electrical events.

- Humidity and Corrosion: Conformal coating and sealed connectors protecting electronics from humidity and salt exposure in harsh climates.

- Thermal Cycling: >1000 cycles between temperature extremes validating solder joint reliability and preventing thermal fatigue failures.

Automotive Reliability Assurance

Through automotive-qualified manufacturing, comprehensive environmental testing, and validated reliability protocols coordinated with quality systems, APTPCB delivers infotainment systems meeting automotive durability requirements supporting 15+ year vehicle lifecycles.

Implementing Navigation and Telematics Integration

Integrated navigation systems require GPS/GNSS receivers, map data storage, real-time traffic integration, and telematics modules connecting to backend services providing navigation guidance, POI search, and connected services. Navigation challenges include maintaining GPS accuracy in urban canyons, providing turn-by-turn guidance with appropriate timing, and updating maps through OTA. Inadequate navigation implementation causes inaccurate position estimates frustrating users, missed turns from delayed guidance, or outdated maps reducing utility — significantly impacting navigation usability and customer satisfaction as navigation becomes expected standard feature.

At APTPCB, our assembly supports comprehensive navigation and telematics integration achieving reliable guidance and connected services.

Navigation Integration Implementation

GPS and Positioning

- Multi-constellation GNSS (GPS, GLONASS, Galileo, BeiDou) improving position accuracy and availability in challenging urban environments.

- Dead reckoning integration combining GPS with vehicle speed and gyroscope maintaining position estimation during GPS loss.

- High-sensitivity receivers maintaining satellite tracking despite windshield attenuation and urban multipath.

- RTK or PPP correction services achieving lane-level accuracy supporting advanced navigation features.

Connected Navigation Services

- Real-time traffic integration routing around congestion optimizing travel time and fuel efficiency.

- Cloud-based POI search accessing comprehensive business and location databases.

- Over-the-air map updates maintaining current navigation data without dealer visits.

- Predictive maintenance and remote diagnostics through telematics backend integration.

Through comprehensive navigation integration and connected services implementation coordinated with component sourcing of qualified modules, APTPCB enables feature-rich infotainment systems supporting modern navigation and connectivity expectations.

Providing Flexible Platform and Customization Support

Automotive infotainment spans diverse segments from entry-level systems with basic functionality through luxury platforms with multiple displays, premium audio, and advanced connectivity requiring scalable architectures, customization options, and regional variants. Platform flexibility challenges include managing diverse configurations, supporting multiple screen sizes, and accommodating regional requirements (languages, radio bands, regulations) while maintaining development efficiency. Inflexible platforms increase development costs, limit market coverage, or delay regional launches — significantly impacting business efficiency and global market competitiveness.

At APTPCB, we support flexible infotainment manufacturing accommodating diverse platform requirements and regional customization.

Platform Flexibility Capabilities

Scalable Architecture

- Modular design supporting entry through premium configurations from common base platform reducing development costs.

- Display size flexibility supporting 7-12 inch screens plus secondary displays through common electronics architecture.

- Audio system scaling from 4-channel basic through 16-channel premium surround sound configurations.

- Regional customization supporting local languages, radio bands, and connectivity requirements.

Manufacturing Support

- Configure-to-order assembly supporting diverse option combinations and customer-specific variants.

- Validation testing across configuration matrix ensuring quality despite product variety.

- Supply chain management maintaining component availability across long automotive product lifecycles.

Through flexible manufacturing and comprehensive customization support coordinated with PCB conformal coating protection, APTPCB enables infotainment manufacturers serving diverse automotive segments from entry through luxury vehicles across global markets.