IPC Class 2 vs Class 3 assembly: scope, decision context, and who this guide is for

Deciding between ipc class 2 vs class 3 assembly standards is one of the most critical procurement decisions for electronic hardware. It is not merely a checkbox on a drawing; it fundamentally dictates the manufacturing process window, inspection criteria, allowable rework, and ultimately, the unit cost. For procurement leads and engineers, understanding this distinction is the difference between paying for unnecessary reliability and facing catastrophic field failures.

This playbook is designed for decision-makers who need to translate product goals into manufacturing specifications. We move beyond the academic definitions of IPC-A-610 and J-STD-001 to focus on the practical implications of these classes. You will learn how to define requirements that protect your product, identify hidden risks in the supply chain, and validate that your manufacturing partner—like APTPCB (APTPCB PCB Factory)—is adhering to the strictures of your chosen class.

Whether you are building dedicated service electronics (Class 2) or high-performance products for harsh environments (Class 3), the rules of engagement change. This guide provides the actionable checklists, validation plans, and risk assessments needed to navigate the ipc class 2 vs class 3 assembly landscape safely and cost-effectively.

ipc class 2 vs class 3 assembly: When to specify IPC Class 2 vs Class 3 (and when it’s overkill)

Understanding the scope of your project is the first step, as the choice between classes dictates the rigor of the entire production line.

IPC Class 2 (Dedicated Service Electronic Products) is the standard for most industrial and consumer electronics where continued performance and extended life are required, but uninterrupted service is not critical.

- Right Approach When: You are building laptops, tablets, general industrial controls, or consumer appliances. The product is expected to function reliably, but a failure does not threaten life or critical infrastructure.

- Wrong Approach When: The device operates in extreme environments (aerospace, downhole drilling) or is a life-support medical device. If downtime is fatal or legally catastrophic, Class 2 is insufficient.

IPC Class 3 (High Performance/Harsh Environment Electronic Products) is the standard for equipment where downtime cannot be tolerated, end-use environment is harsh, and the equipment must function when required.

- Right Approach When: You are designing automotive safety systems (airbags, braking), aerospace avionics, military defense systems, or implantable medical devices. The cost of failure outweighs the higher manufacturing cost.

- Wrong Approach When: You are building a consumer gadget or a simple IoT sensor. Specifying Class 3 for non-critical items adds 15-30% to the cost (due to inspection and lower yields) without delivering perceived value to the end user.

ipc class 2 vs class 3 assembly: What to specify on drawings and POs (so quotes match reality)

Once you have determined the appropriate class, you must translate that high-level choice into specific engineering requirements to ensure the factory quotes accurately.

- Through-Hole Barrel Fill:

- Class 2: Requires 50% vertical fill of solder in the plated through-hole.

- Class 3: Requires 75% vertical fill. This often demands different wave soldering profiles or selective soldering parameters.

- Surface Mount Solder Joint Width:

- Class 2: The side overhang of the termination is allowed up to 50% of the termination width.

- Class 3: The side overhang is allowed only up to 25%. This requires tighter pick-and-place accuracy and stencil design.

- Component Placement Accuracy:

- Class 2: Allows for some visual misalignment provided the electrical connection is solid and minimum overlap is met.

- Class 3: Stricter alignment criteria; components must be centered more precisely to ensure mechanical stability under vibration.

- Voiding Criteria (BGA/QFN):

- Class 2: Generally allows up to 25% voiding area in the solder ball (depending on specific agreements).

- Class 3: Often restricts voiding to <20% or even tighter for specific high-reliability industries, requiring X-ray validation on every board.

- PCB Plating Thickness:

- Class 2: Average copper plating in holes is typically 20µm (0.79 mil).

- Class 3: Average copper plating must be 25µm (1.0 mil) to withstand thermal shock and expansion without cracking.

- Cleanliness and Ionic Contamination:

- Class 2: Standard wash processes are usually sufficient; ROSE testing limits are standard.

- Class 3: May require stricter ionic contamination limits (e.g., <1.56 µg/cm² NaCl equivalent) and more aggressive cleaning chemistries.

- Visual Inspection Coverage:

- Class 2: Sampling inspection (AQL) is often acceptable for large batches.

- Class 3: 100% visual or AOI inspection is typically mandatory to ensure zero defects escape.

- Rework Limitations:

- Class 2: Rework is generally permitted if it meets the final visual criteria.

- Class 3: Rework is heavily restricted. Some defects cannot be reworked without customer waiver; the number of heat cycles per pad is limited.

- Material Selection (Laminate):

- Class 2: Standard FR4 (Tg 130-140°C) is common.

- Class 3: Often requires High-Tg (170°C+) or specialized materials (Rogers, Polyimide) to survive the harsher qualification testing.

- Documentation Package:

- Class 2: Standard Certificate of Compliance (CoC).

- Class 3: Full traceability down to the component lot, detailed test reports, and cross-section analysis reports are often required deliverables.

ipc class 2 vs class 3 assembly: Scale-up risks that drive cost or early failures

Even with clear requirements, the transition from prototype to volume production reveals hidden risks inherent to the ipc class 2 vs class 3 assembly distinction.

- The "Over-Spec" Cost Spiral:

- Risk: Engineers specify Class 3 "just to be safe" for a Class 2 product.

- Why: Fear of failure drives conservative specs.

- Detection: Quote comes in 30% higher than market average; supplier asks for waivers on minor cosmetic issues.

- Prevention: Review the "Cost of Failure" vs. "Cost of Quality." Only use Class 3 if the environment or safety demands it.

- The Rework Trap:

- Risk: A Class 3 production run has a 5% yield fallout, but the supplier attempts unauthorized rework to save the boards.

- Why: Scrap costs for Class 3 are high; suppliers try to minimize loss.

- Detection: Reliability testing shows early failures; solder joints look dull or grainy (signs of multiple reflows).

- Prevention: Explicitly define rework limits in the contract. Demand a "scrap log" for Class 3 runs.

- Inspection Bottlenecks:

- Risk: Production slows down significantly because the factory's AOI (Automated Optical Inspection) is set to Class 3 sensitivity, flagging false calls.

- Why: AOI basics dictate that higher sensitivity equals more false positives, requiring human review.

- Detection: Lead times slip; "WIP" (Work in Progress) piles up at the inspection station.

- Prevention: Calibrate AOI thresholds during the NPI phase. Ensure the supplier has enough skilled inspectors for verification.

- Barrel Fill Failure in Wave Soldering:

- Risk: Through-hole components fail to meet the 75% fill requirement for Class 3.

- Why: Thermal relief design on the PCB is insufficient, or the wave dwell time is too short.

- Detection: X-ray or cross-section analysis reveals voids or insufficient solder height in the barrel.

- Prevention: Perform DFM specifically for thermal relief. Use selective soldering for heavy copper boards.

- Component Tolerance Mismatch:

- Risk: Class 3 pads are designed for nominal component sizes, but a second-source component is at the tolerance limit.

- Why: Supply chain shortages force component swaps.

- Detection: Toe or heel fillets fail Class 3 visual criteria.

- Prevention: Validate all alternative components against the PCB footprint before approval.

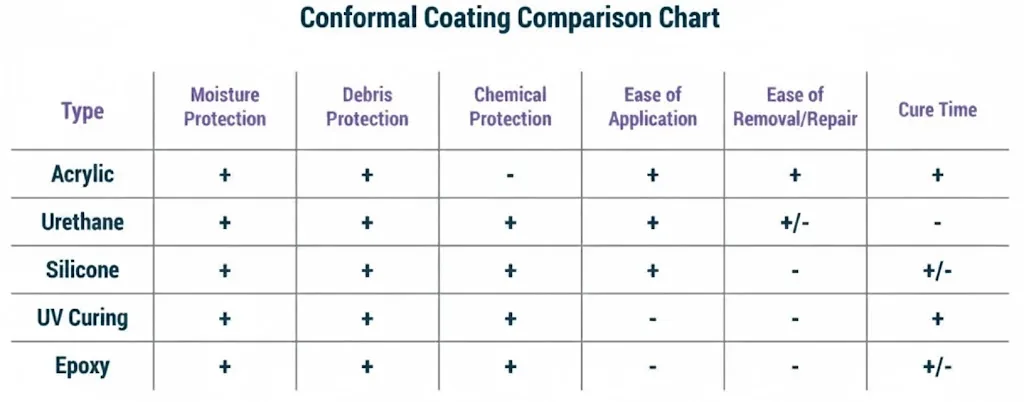

- Cleanliness & Conformal Coating Adhesion:

- Risk: Residues acceptable in Class 2 cause delamination of conformal coating in Class 3 applications.

- Why: Class 3 often implies harsh environments requiring coating; residues prevent bonding.

- Detection: Coating peels off during tape test or thermal cycling.

- Prevention: Specify ionic contamination limits and test surface energy before coating.

- The "Class 2 Board, Class 3 Assembly" Conflict:

- Risk: You order a bare PCB built to Class 2 specs (20µm plating) but demand Class 3 assembly.

- Why: Procurement splits the PCB fabrication and assembly orders without syncing specs.

- Detection: Barrels crack during the higher thermal stress of Class 3 assembly/rework.

- Prevention: Ensure the bare board fabrication note explicitly matches the assembly class requirement (IPC-6012 Class 3 for the bare board).

- Documentation Gaps:

- Risk: Parts arrive without the traceability required for a Class 3 audit.

- Why: Supplier treats it as a standard run and doesn't log lot codes.

- Detection: You fail an external audit (e.g., FDA, AS9100) because you can't trace a bad capacitor batch.

- Prevention: Make the "Data Package" a line item on the PO that must be delivered before payment.

ipc class 2 vs class 3 assembly validation and acceptance (tests and pass criteria)

To ensure your ipc class 2 vs class 3 assembly requirements are met, you need a structured validation plan that goes beyond a simple visual check.

- Microsection Analysis (Cross-Sectioning):

- Objective: Verify plating thickness and solder barrel fill.

- Method: Cut a sample coupon or PCB, polish it, and view under a microscope.

- Acceptance: Class 2: >20µm copper, >50% fill. Class 3: >25µm copper, >75% fill, no internal cracks.

- X-Ray Inspection (Automated or Manual):

- Objective: Check BGA/QFN solder joints and voiding.

- Method: Transmissive X-ray or 3D CT scan.

- Acceptance: Voiding <25% (Class 2) or <20% (Class 3). No bridging or open circuits.

- Solderability Testing (J-STD-003):

- Objective: Ensure PCB pads and component leads accept solder properly.

- Method: Dip and look test or wetting balance test.

- Acceptance: >95% coverage of the surface with a smooth, continuous solder coating.

- Ionic Contamination Testing (ROSE Test):

- Objective: Verify board cleanliness to prevent corrosion/dendrite growth.

- Method: Resistivity of Solvent Extract (ROSE).

- Acceptance: <1.56 µg/cm² NaCl equivalent (or per specific industry standard).

- Shear/Pull Testing:

- Objective: Verify mechanical strength of solder joints.

- Method: Apply force to specific components until failure.

- Acceptance: Fracture should occur in the bulk solder or component, not at the intermetallic layer (which indicates brittle joints).

- Thermal Cycling (Reliability Stress Screening):

- Objective: Simulate life-cycle stress to catch early failures.

- Method: Cycle between -40°C and +85°C (or higher) for set cycles.

- Acceptance: No electrical opens, no barrel cracks, no solder joint fatigue cracks.

- First Article Inspection (FAI):

- Objective: Verify the process setup before volume run.

- Method: 100% measurement of all dimensions and values on the first 3-5 boards.

- Acceptance: Report must match BOM and Gerber files 100%.

- AOI Capability Verification:

- Objective: Ensure aoi basics are correctly implemented for the class.

- Method: Run a "Gold Board" and a known "Defect Board" through the machine.

- Acceptance: Machine must catch all planted defects without excessive false calls.

- Flying Probe / ICT Testing:

- Objective: Electrical verification of every net.

- Method: Automated probes check resistance, capacitance, and continuity.

- Acceptance: 100% pass on netlist comparison.

- Peel Strength Test (for Flex PCBs):

- Objective: Ensure copper adhesion on flexible substrates.

- Method: Pull copper strip at 90 degrees.

- Acceptance: Meets IPC-TM-650 specs for the specific laminate.

ipc class 2 vs class 3 assembly supplier qualification checklist (RFQ, audit, traceability)

Use this checklist when engaging with APTPCB or any manufacturing partner to ensure they are aligned with your ipc class 2 vs class 3 assembly needs.

RFQ inputs for ipc class 2 vs class 3 assembly (what you provide)

- IPC Class Callout: Explicitly state "Build to IPC-A-610 Class [2/3]" on the Fab Drawing and PO.

- Bare Board Spec: Reference IPC-6012 Class [2/3] for the PCB fabrication.

- Gerber Files: RS-274X or ODB++ format.

- Centroid/Pick-and-Place File: With X, Y, Rotation, and Side data.

- BOM: With Manufacturer Part Numbers (MPN) and approved alternates.

- Assembly Drawings: Showing orientation, special masking, or potting requirements.

- Test Requirements: Specific instructions for ICT, FCT, or Burn-in.

- Volume & EAU: Estimated Annual Usage to help supplier plan capacity.

Capability evidence for ipc class 2 vs class 3 assembly (what the supplier should show)

- Certifications: ISO 9001 (General), ISO 13485 (Medical), AS9100 (Aerospace), IATF 16949 (Automotive).

- IPC Trainers: Do they have an in-house IPC Certified IPC Trainer (CIT)?

- Equipment List: Do they have 3D SPI (Solder Paste Inspection) and 3D AOI?

- X-Ray Capability: Is it inline or offline? What is the resolution?

- Conformal Coating: Automated spray or manual dip?

- Cleanliness Lab: Do they have an in-house ROSE tester or Ion Chromatography?

Quality system and traceability for ipc class 2 vs class 3 assembly

- Defect Classification SMT: How do they define and log defects? Can they show a sample Pareto chart?

- Traceability Level: Can they link a specific PCB serial number to the solder paste batch and reflow profile used?

- MRB Process: How do they handle Material Review Board decisions for non-conforming parts?

- Calibration: Are all ovens and torque drivers calibrated to NIST/national standards?

- ESD Control: Do they have a robust ESD program (flooring, wrist straps, continuous monitoring)?

- Training Records: Are operators certified to the specific IPC class they are working on?

Change control and delivery for ipc class 2 vs class 3 assembly

- PCN Policy: Will they notify you before changing solder paste, flux, or cleaning agents?

- First Article Process: Do they require FAI approval before full production?

- Packaging: Is ESD packaging defined (moisture barrier bags, desiccant)?

- Scrap Policy: How is Class 3 scrap destroyed/recorded?

- Capacity Planning: Can they handle a 20% surge in demand without compromising Class 3 rigor?

- Data Retention: How long do they keep quality records (Class 3 often requires 5-10 years)?

How to choose ipc class 2 vs class 3 assembly (trade-offs and decision rules)

Every engineering decision involves a trade-off. Here is how to navigate the compromises inherent in ipc class 2 vs class 3 assembly.

- Reliability vs. Cost:

- If you prioritize absolute reliability (Class 3), expect a 15-30% higher unit cost due to slower processing, higher inspection overhead, and lower yields.

- If you prioritize cost (Class 2), you accept a statistically higher risk of latent defects, which is acceptable for disposable or easily replaceable goods.

- Inspection Depth vs. Throughput:

- If you prioritize zero escapes (Class 3), choose 100% AOI + X-Ray sampling. This creates a production bottleneck but ensures quality.

- If you prioritize speed (Class 2), choose batch sampling or AQL inspection.

- Rework vs. Scrap:

- If you prioritize board integrity (Class 3), you must accept higher scrap rates because rework is restricted to prevent thermal damage.

- If you prioritize yield (Class 2), allow controlled rework to salvage functional boards.

- Design Density vs. Manufacturability:

- If you prioritize miniaturization (HDI, fine pitch), Class 3 becomes exponentially harder to achieve due to tighter annular ring and plating requirements.

- If you prioritize Class 3 compliance, relax the density rules (larger pads, wider tracks) to give the manufacturer a larger process window.

- Material Lead Time vs. Performance:

- If you prioritize thermal performance (Class 3), you may need specialized laminates (e.g., Polyimide) which have longer lead times than standard FR4.

- If you prioritize speed-to-market, design for standard FR4 materials compatible with Class 2.

ipc class 2 vs class 3 assembly FAQ (cost, lead time, Design for Manufacturability (DFM) files, stackup, Automated Optical Inspection (AOI) inspection, X-ray inspection)

Q: Can I mix IPC classes on the same board? A: Generally, no. The entire assembly process (reflow profile, cleaning, inspection) is set for the highest requirement. However, you can specify "Class 2 with Class 3 plating requirements" in your fabrication notes if needed.

Q: Does Class 3 always require lead-free solder? A: No. IPC classes define the quality of the connection, not the alloy. In fact, many aerospace/defense Class 3 products still use Tin-Lead (SnPb) solder for its known reliability and whisker mitigation.

Q: How much does upgrading from Class 2 to Class 3 increase the price? A: Typically 15% to 30%. This covers the extra plating time (PCB fab), slower assembly speeds, mandatory 100% inspection, and the cost of potential scrap that cannot be reworked.

Q: What is the difference in "Defect Classification SMT" between classes? A: A condition marked as a "Process Indicator" in Class 2 (acceptable but not ideal) might be a "Defect" in Class 3 (must be rejected). For example, a 26% overhang on a component is a defect in Class 3 but acceptable in Class 2.

Q: Do I need special Gerber files for Class 3? A: The files are the same format, but the design rules inside them should differ. Class 3 designs should have larger annular rings and pad geometries to accommodate the stricter manufacturing tolerances.

Q: Can APTPCB handle Class 3 assembly? A: Yes. APTPCB has the certifications, equipment (3D AOI, X-Ray), and process controls required to manufacture and inspect to IPC Class 3 standards for high-reliability industries.

Q: Is AOI mandatory for Class 2? A: It is not strictly mandatory by IPC code, but highly recommended. For Class 3, automated inspection is practically essential to meet the 100% inspection requirement efficiently.

Q: What happens if I don't specify a class? A: The industry default is IPC Class 2. If you need Class 3 and don't specify it, you will receive Class 2 boards that may fail your internal validation or field requirements.

Resources for ipc class 2 vs class 3 assembly (related pages and tools)

- AOI Inspection Services – Understand how aoi basics are applied differently for Class 2 vs. Class 3 to catch defects early.

- PCB Quality Standards – A deep dive into the certifications and quality systems that underpin high-reliability manufacturing.

- Medical PCB Assembly – See how Class 3 standards are applied in real-world life-critical medical devices.

- Aerospace & Defense PCB – Explore the rigorous requirements for avionics and defense electronics where failure is not an option.

- SMT & THT Assembly – Learn about the specific process controls for Surface Mount and Through-Hole technologies.

Request a quote for ipc class 2 vs class 3 assembly (Design for Manufacturability (DFM) review + pricing)

Ready to validate your design for ipc class 2 vs class 3 assembly? APTPCB provides a comprehensive DFM review alongside your quote to highlight potential compliance issues before production begins.

To get an accurate quote and DFM, please provide:

- Gerber Files: (RS-274X or ODB++)

- BOM: (Excel format with MPNs)

- Assembly Drawings: Clearly stating IPC Class 2 or 3.

- Volume: Prototype quantity vs. Mass production targets.

- Testing Requirements: (ICT, FCT, or specific validation steps).

Click here to Request a Quote & DFM Review

Conclusion (next steps)

The choice between ipc class 2 vs class 3 assembly is a strategic balance of risk, reliability, and cost. Class 2 offers a robust, cost-effective solution for the majority of electronics, while Class 3 provides the uncompromising assurance needed for critical systems. By defining your requirements clearly, validating your supplier’s capabilities, and implementing a rigorous inspection plan, you ensure that your product performs exactly as intended in the field.