Laptop PCB assemblies integrate desktop-class processors (45-125W TDP), discrete graphics, high-speed memory (DDR5), NVMe storage, and comprehensive I/O supporting ultraportable productivity devices, high-performance gaming platforms, and professional workstations requiring sophisticated thermal management, robust power delivery, and validated reliability supporting 3-7 year operational lifecycles with thousands of charge cycles, temperature variations, and mechanical stress from portable use across consumer, business, and creative professional markets.

At APTPCB, we deliver specialized laptop assembly services implementing advanced thermal interfaces, high-current power delivery, and comprehensive testing with turnkey assembly capabilities supporting ultrabook designs through 17-inch gaming platforms.

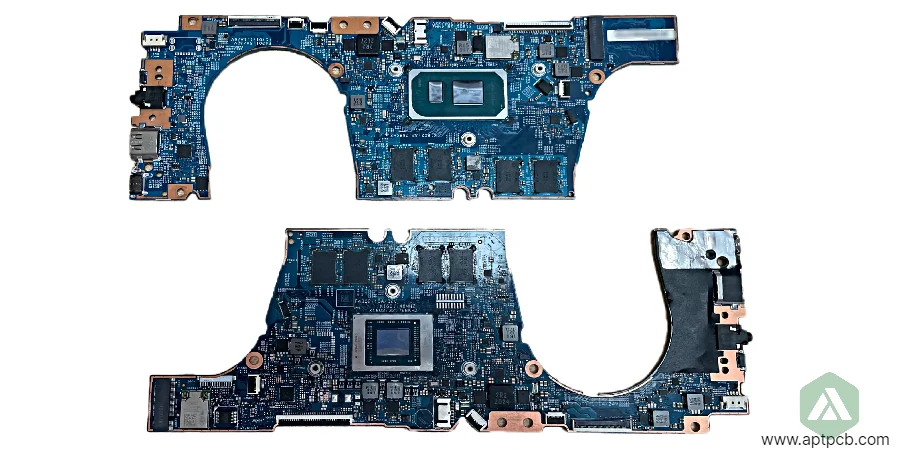

Implementing High-Performance Processor and Graphics Integration

Laptop motherboards accommodate processors dissipating 15-125W and optional discrete graphics adding 50-175W requiring sophisticated VRM designs delivering hundreds of amperes, precision thermal interface attachment, and validated power sequencing. Integration challenges include managing voltage transients during CPU boost events, coordinating graphics switching between integrated and discrete GPUs, and maintaining signal integrity across high-speed processor interfaces. Inadequate processor integration causes system instability from power delivery issues, thermal throttling limiting performance, or graphics switching failures frustrating users — significantly impacting user experience, benchmark performance, and product reviews especially for gaming and workstation platforms where performance is critical.

At APTPCB, our assembly implements validated processor and graphics integration achieving performance specifications.

Processor Integration Implementation

- Multi-Phase VRM Design: 4-12 phase voltage regulators delivering clean power at high currents with fast transient response supporting CPU turbo boost and testing quality validation.

- Precision Thermal Interface Application: Automated TIM dispensing and heatsink mounting maintaining <0.2°C/W thermal resistance for optimal cooling performance.

- Graphics Switching Coordination: Mux or muxless designs enabling seamless transition between integrated and discrete graphics optimizing power and performance.

- High-Speed Interface Routing: PCIe Gen4/5 differential pairs supporting discrete graphics and NVMe storage maintaining signal integrity across motherboard.

- Power Sequencing Logic: Coordinated voltage rail activation meeting processor requirements preventing latch-up or improper initialization.

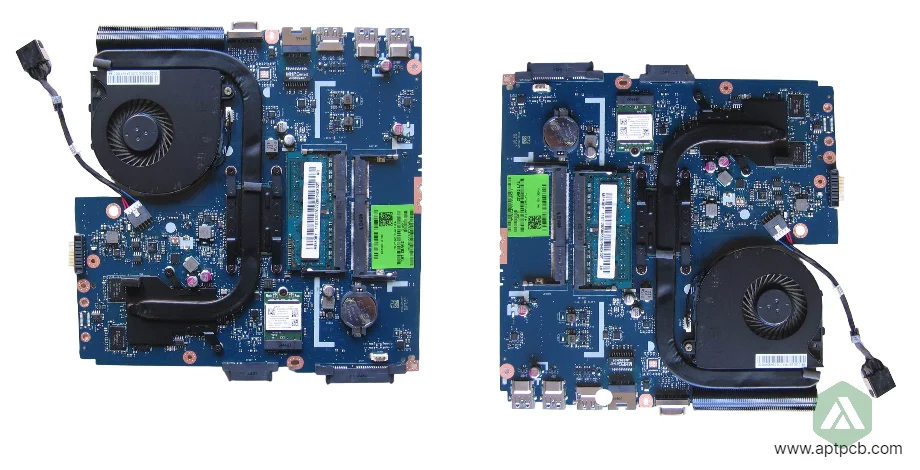

Managing Thermal Dissipation in Thin Chassis

Gaming and performance laptops dissipate 100-300W total system power in chassis <20mm thick requiring advanced cooling with vapor chambers, heat pipes, and high-CFM fans maintaining processor and graphics temperatures below throttling thresholds. Thermal management challenges include distributing heat from concentrated sources, managing airflow in constrained spaces, and balancing cooling performance against acoustic noise. Inadequate thermal design causes aggressive throttling reducing performance 30-50%, uncomfortable palm rest temperatures affecting usability, or excessive fan noise disturbing users — significantly impacting performance benchmarks, user comfort, and product competitiveness especially for gaming laptops where sustained performance is expected.

At APTPCB, our manufacturing coordinates thermal solution integration achieving thermal and acoustic specifications.

Thermal Management Implementation

- Vapor Chamber Integration: Large vapor chambers spreading heat from processors and graphics enabling efficient transfer to heat sink fins.

- Multi-Heatpipe Design: 2-7 heat pipes distributing thermal load across multiple cooling fins optimizing heat dissipation in available chassis space.

- High-Performance Thermal Compounds: Liquid metal or premium paste TIMs achieving <0.15°C/W thermal resistance improving cooling headroom 5-10°C.

- Advanced Fan Control: PWM fan management with acoustic optimization maintaining cooling while minimizing noise through functional testing validation.

Supporting Comprehensive I/O and Connectivity

Laptops provide diverse I/O including USB-C/Thunderbolt, HDMI, Ethernet, audio, SD card supporting connectivity to displays, storage, networks, and peripherals requiring careful interface implementation, EMI management, and ESD protection. I/O challenges include Thunderbolt certification requiring strict electrical compliance, HDMI 2.1 supporting 4K120 or 8K60 displays, and USB4 enabling 40Gbps data plus power delivery. Inadequate I/O implementation causes connectivity issues frustrating users, electromagnetic interference affecting wireless, or ESD damage requiring repairs — significantly impacting usability, professional workflow support, and long-term reliability especially for docking station and external display usage.

At APTPCB, our assembly supports comprehensive I/O integration meeting interface specifications.

I/O Implementation Techniques

- Thunderbolt 4 Integration: Certified Thunderbolt controllers with compliant routing supporting 40Gbps data, dual 4K displays, and 100W charging with quality system compliance.

- USB-C Power Delivery: PD controllers negotiating up to 240W charging supporting high-performance gaming laptops through standard USB-C connectors.

- Multi-Display Support: HDMI 2.1 and DisplayPort outputs supporting external 4K displays plus internal panel for multi-monitor productivity workflows.

- ESD Protection Networks: TVS diodes on all external interfaces preventing damage from electrostatic discharge during connector insertion.

Providing Enterprise and Gaming Platform Support

Business laptops require enterprise management (Intel vPro, AMD PRO), security features (TPM, fingerprint, IR camera), and long lifecycle support while gaming platforms demand RGB lighting control, overclocking support, and high-refresh displays. Platform-specific requirements influence component selection, firmware development, and validation testing supporting specialized markets. Inadequate enterprise features limit corporate deployments, insufficient gaming optimizations reduce competitive positioning, or poor platform support complicates IT management — significantly impacting market suitability, customer satisfaction, and total cost of ownership across business and gaming segments.

At APTPCB, we support specialized laptop platforms with comprehensive manufacturing capabilities.

Platform Support Capabilities

Enterprise Business Laptops

- vPro/PRO processor integration supporting remote management and AMT capabilities for IT departments.

- Security module integration (TPM 2.0, fingerprint readers, IR cameras) supporting Windows Hello and enterprise authentication.

- Extended lifecycle support (5-7 years) maintaining component availability and long-term serviceability.

- Validation and certification supporting enterprise purchasing requirements and compatibility testing.

Gaming Performance Platforms

- RGB lighting integration with synchronized control across keyboard, chassis, and peripherals.

- Overclocking support and performance tuning enabling power users optimizing system performance.

- High-refresh display support (144-360Hz) with adaptive sync providing smooth gaming experience.

- Advanced cooling solutions and performance modes supporting sustained high-power operation during gaming sessions.

Enabling Flexible Manufacturing and Customization

Laptop manufacturing requires flexibility supporting diverse SKUs (processor, memory, storage, display options), regional variants (keyboard layouts, wireless configurations), and customer-specific customization while maintaining quality and delivery schedules. Manufacturing challenges include managing complex BOMs, build-to-order production, and late-stage customization supporting e-commerce business models. Inflexible manufacturing approaches increase inventory costs, delay deliveries, or limit customization options reducing competitive positioning — significantly impacting business efficiency, customer satisfaction, and market responsiveness especially for direct-sales business models.

At APTPCB, we provide flexible laptop manufacturing supporting diverse configuration and volume requirements.

Manufacturing Flexibility

- Configure-to-Order Support: Flexible assembly accommodating customer-specific configurations assembled from common platforms reducing inventory.

- Rapid Configuration Changes: Quick changeover between SKUs supporting e-commerce fulfillment and just-in-time manufacturing.

- Quality Management: Comprehensive testing across all configurations ensuring consistent quality despite product variety through NPI assembly validation.

- Volume Scalability: Manufacturing capacity supporting thousands to hundreds of thousands of units annually across consumer and enterprise segments.

Through comprehensive platform support, flexible manufacturing, and validated quality processes coordinated with mass production capabilities, APTPCB enables laptop manufacturers deploying successful products across ultrabook, mainstream, gaming, and workstation markets.