LEDs show up everywhere now: streetlights, automotive lamps, architectural strips, display backlights, signage, smart home devices, industrial indicators and more. No matter how attractive the optics or enclosure design is, every LED product lives or dies on something less visible:

- the PCB that manages heat and current, and

- the assembly quality that holds everything together for thousands of hours.

If the LED PCB runs too hot, solders poorly, or is assembled inconsistently, you get dimming, color shift, failures in the field—and costly warranty issues.

APTPCB is a full-service PCB & PCBA manufacturer, not a LED-only shop. We build:

- FR-4, high-Tg, HDI, flex and rigid-flex PCBs

- aluminum and copper MCPCBs

- ceramic and special-material PCBs

and we assemble everything from simple indicator boards to complex driver/control electronics. This article focuses on how we approach LED PCB manufacturing and assembly as a complete, integrated service.

The Crucial Interplay: LED PCB Manufacturing Fundamentals

A reliable LED assembly starts with a PCB that can safely carry current and move heat away from the LED junction. For LED products, PCB manufacturing is not just “make a board” – it’s a thermal and electrical design problem that has to match your mechanical and optical concept.

Material Choices That Define LED PCB Performance

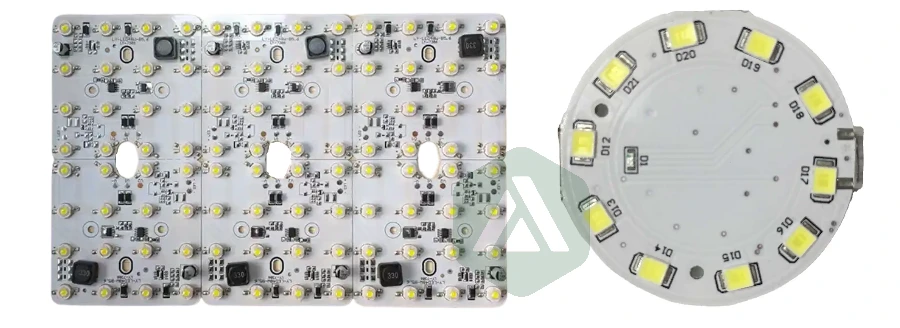

Different LED applications need different PCB platforms. We routinely manufacture:

FR-4 LED PCBs – for low/medium power and control boards

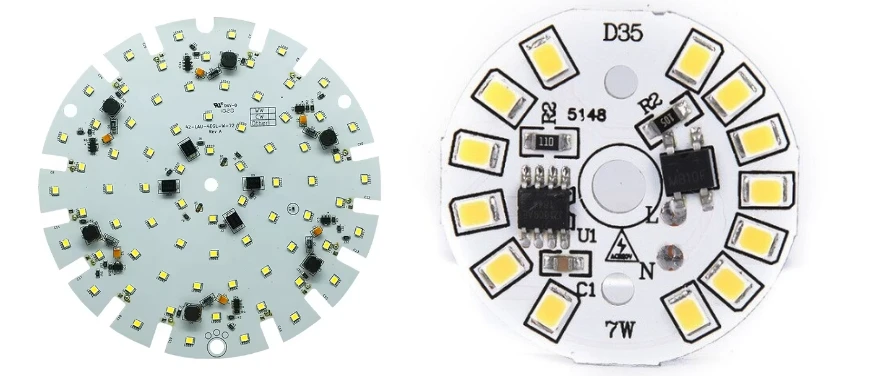

Ideal for status LEDs, displays, and control logic where heat is moderate or handled by the housing. FR-4 LED PCBs are often used together with separate heatsinks or metal chassis.Metal Core PCBs (MCPCBs) – for high-power LEDs

Aluminum or copper-core MCPCBs use a thermally conductive dielectric bonded to a metal base. This stack-up pulls heat from the LED pad into the metal core quickly. We control dielectric thickness and bonding quality to achieve both thermal performance and electrical isolation.Ceramic PCBs – for extreme conditions and COB

Alumina and aluminum nitride substrates offer very high thermal conductivity, excellent insulation, and good CTE matching to LED chips. They are widely used in COB (chip-on-board) modules, automotive headlamps and demanding industrial or medical lighting.

In many projects, these appear together: MCPCB or ceramic for the LED engine, FR-4 for drivers and control, flex or rigid-flex for interconnects. As a general PCB factory, we can build and coordinate all of them under one process umbrella.

Manufacturing Details that Matter for LED Boards

Beyond the base material, several fabrication decisions have a direct impact on LED behavior:

- Dielectric Lamination (for MCPCB)

The thermally conductive dielectric layer must be uniform and void-free. We tune lamination parameters so that thermal resistance and breakdown voltage match your LED’s power level and safety requirements. - Copper Thickness and Heat Spreading

Higher copper weights (2–6 oz and above) can improve both current capacity and lateral heat spreading. We balance copper thickness with manufacturability and fine-pitch requirements around drivers and control ICs. - Thermal Vias in FR-4 Designs

For FR-4 LED PCBs, plated thermal vias under LED pads and in power areas help move heat to inner planes, back panels or dedicated heatsinks. We design via patterns to avoid solder voids and maintain mechanical strength. - White and Special Solder Masks

For lighting applications, white solder mask improves reflectivity and visual appearance. We select resins and processes that minimize yellowing and staining over time, especially for high-temperature environments.

DFM for LED PCBs: Fixing Issues Before They Reach Production

Our engineering team reviews LED PCB designs as part of our standard PCB fabrication process. For LED boards, DFM focuses on:

- thermal paths from LED pads to core or heatsink

- trace widths and copper areas for both current and heat

- clearances for high-voltage LED drivers and safety approvals

- panelization that supports reliable depaneling and automated assembly

The result is a PCB that not only passes design checks on paper, but also runs smoothly on a real production line and supports stable LED performance over its lifetime.

Precision at Work: The LED PCB Assembly Process

Once the LED PCBs are fabricated correctly, assembly becomes the next critical step. LEDs are sensitive to temperature, mechanical stress and contamination, so LED PCB assembly has to be both precise and repeatable.

Component Sourcing and Preparation

Qualified Supply Chain

We source LEDs, drivers, MOSFETs, passives, connectors and other parts through vetted channels. For LEDs in particular, consistency of bin (color, flux, Vf) is crucial to avoid visible variation.Incoming Quality Control (IQC)

Components are checked against datasheets and BOM—package, marking, dimensions, and in some cases sample testing, especially for LEDs and power devices.Moisture and ESD Handling

Sensitive components (MSL, ESD) are stored and handled with proper controls to avoid latent defects that only show up in the field.

Solder Paste Printing and SPI

Stencil Design for LED Pads

LED thermal pads need enough paste for a solid, void-minimized joint but not so much that parts float or tilt. We adjust aperture shapes and reduction rates accordingly.Automated Solder Paste Printing

High-precision printers ensure uniform paste volume across large LED panels.2D/3D Solder Paste Inspection (SPI)

SPI checks height, volume and position of paste deposits—especially important for large LED pads and fine-pitch driver ICs.

SMT Placement and Reflow

High-Speed Pick-and-Place

Our SMT lines place tiny chip LEDs, mid-power packages, high-power LEDs, drivers, microcontrollers, and small passives on FR-4, MCPCB and ceramic substrates.Vision Alignment and Polarity Check

Cameras verify LED orientation, polarity, and position. Misplaced or rotated LEDs can ruin an entire panel, so we lock this down early.Reflow Profile Tuning

MCPCBs and ceramic boards behave differently from FR-4 in the oven. We create dedicated temperature profiles to ensure:- good wetting on LED pads

- minimal voids under thermal pads

- no overheating or discoloration of LEDs and solder masks

Through-Hole and Mixed-Technology Assembly

Where through-hole parts are used—connectors, large capacitors, transformers, etc.—we combine:

- wave soldering

- selective soldering

- or hand soldering for special parts

to keep joints robust while controlling heat exposure for populated LED areas.

Cleaning and AOI

Post-Reflow Cleaning (When Required)

Flux residues are removed where reliability or appearance demands it, especially in outdoor or harsh environments.Automated Optical Inspection (AOI)

AOI checks for missing components, wrong parts, polarity, tombstones, bridges, and other issues. For LED arrays, consistent placement and alignment also affect optical uniformity.

For new designs, our NPI and small-batch PCB manufacturing service lets us debug and tune the assembly process on small runs before you commit to volume.

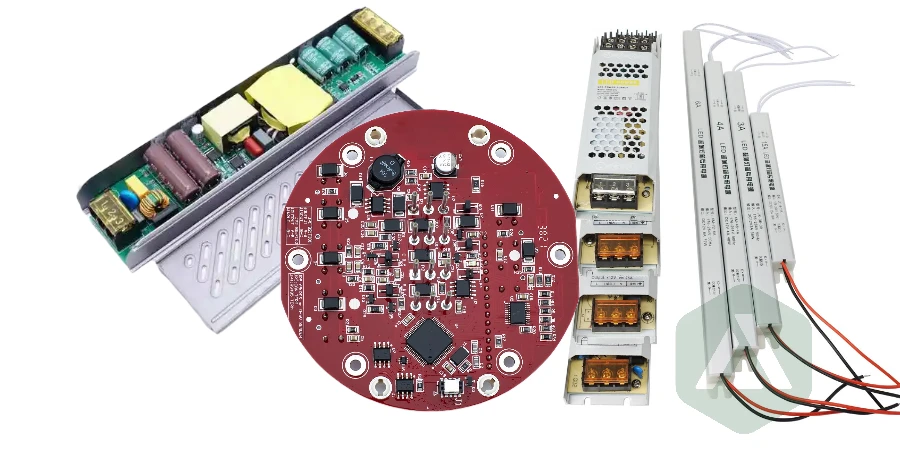

Beyond the LED PCB: Assembling Peripheral Electronics

A real LED product is more than an LED board. It usually includes drivers, control electronics, communication modules and user interfaces. Because APTPCB is a general PCB and assembly provider, we can assemble the entire electronic system, not just the LED panel.

Driver and Power Boards

Stable Power for LEDs

Constant-current/constant-voltage drivers, PFC stages, AC-DC or DC-DC modules are assembled on FR-4, MCPCB or hybrid boards.High-Voltage / High-Current Design

We respect creepage, clearance, and trace width requirements for mains circuits and high-current paths, integrating thermal vias and copper pours where needed.Thermal Handling for Drivers

Power ICs and MOSFETs often need their own thermal strategy. We combine PCB features (thermal vias, heavy copper, copper inlays) with heatsink or case interfaces.

Control, Communication and Logic Boards

Dense SMT for Intelligence

We assemble microcontrollers, wireless modules (Wi-Fi, BLE, Zigbee), bus interfaces (DALI, DMX), and logic circuits with fine-pitch and high-density layouts.In-Circuit Programming and Test Points

Programming of firmware and bootloaders can be integrated into the assembly line so control boards arrive ready to use.

Sensors and User Interfaces

Sensor Integration

Motion, ambient light, temperature and other sensors are often co-located or connected via flex. We assemble and test these to make lighting “smart” rather than just on/off.Switches, Encoders, Displays, Connectors

We handle the mix of SMT and through-hole required by user interfaces and wiring harnesses—important for wall switches, control panels, luminaires and fixtures.

Flex and Rigid-Flex for Form Factor and Connectivity

- Flex and Rigid-Flex Assembly

For automotive, wearable or architectural lighting, flexible PCBs and rigid-flex designs allow unique shapes and compact modules. We assemble components directly on flex or use flex as interconnect between boards.

By letting us build LED engines, driver boards, communication modules and interface boards together, you reduce supplier count and integration risk, and get a system that is electrically and mechanically aligned from day one.

Quality Assurance and Testing for LED Products

For LED products, failures are highly visible—literally. A dark pixel, a dim segment, or a color mismatch is obvious to the end user. That’s why our LED PCB manufacturing and assembly process is backed by structured, multi-stage quality control.

Incoming Material Control

Bare PCB Checks

We inspect LED MCPCBs, ceramics and FR-4 boards for dimensions, layer registration, copper thickness, solder mask quality, and continuity.Component IQC

LEDs and drivers are verified against specifications—binning, forward voltage, packaging, and in some cases sample testing of optical or electrical performance.

In-Process Controls

SPI & AOI

Solder paste inspection and automated optical inspection catch many defects before they leave the line: insufficient paste, bridges, misalignment, wrong polarity, missing parts, etc.First Article Inspection (FAI)

For new products, the first assembled board is thoroughly checked against the BOM and assembly drawings before full production continues.

Electrical and Functional Testing

X-Ray (AXI) for Hidden Joints

Where needed (e.g. certain LED packages, QFNs, BGAs in driver/control boards), X-ray reveals voids and hidden solder issues.In-Circuit Test (ICT)

ICT checks for shorts, opens, wrong values and missing components on boards designed for fixture-based testing—especially useful for complex driver/control assemblies.Functional Test (FCT) for LED Boards

Depending on customer requirements, we can test:- LED illumination and basic on/off behavior

- brightness and color consistency across arrays (within defined tolerances)

- driver output (current/voltage) and dimming curves

- control interfaces (e.g. DALI, DMX, PWM, wireless commands)

- basic thermal behavior under load on a sample basis

Visual Inspection

Final visual inspection covers cleanliness, conformal coating (if used), connector integrity and overall workmanship.

Reliability and Life Tests (Sampling)

Thermal Cycling

Sample boards are cycled between temperature extremes to validate solder and material robustness.Burn-In

Extended operation under realistic load and environment helps catch early-life failures and validate design margins.

Built-In Commitment to PCB Quality

All of this sits within our broader PCB quality system. LED products benefit from the same discipline we apply to automotive, industrial, communication and other markets—shared processes, not isolated “LED-only” lines.

Choosing APTPCB: Your Partner for End-to-End PCB Solutions

When you choose a manufacturing partner for LED products, you’re not just buying a panel of LEDs. You’re trusting someone to handle:

- materials and stack-ups

- thermal behavior

- assembly quality

- driver and control electronics

- test strategy and scalability

APTPCB’s strength is that we are a general PCB and assembly factory with strong LED experience—not a narrow, single-technology shop.

Broad Capabilities, LED Included

We support:

- single- and double-sided boards

- HDI and high-layer-count designs up to complex multi-layer laminated structures

- FR-4, high-Tg, RF materials, flex, rigid-flex, aluminum and copper core MCPCBs, ceramics and more

- SMT, through-hole, mixed technology, fine-pitch, BGA and COB assembly

So your LED engine, power supply, logic controller and communication module can all come from the same place.

Integrated Manufacturing + Assembly

Because fabrication and assembly sit under one roof:

- you avoid shipping bare boards between vendors

- stack-up and panelization decisions are made with assembly in mind

- issues are solved quickly by one cross-functional team

- prototype-to-production transitions are smoother and faster

Engineering Collaboration

Our engineers can support you with:

- DFM for both PCB and PCBA

- material and stack-up recommendations for thermal and electrical performance

- suggestions on panelization, test strategy and cost optimization

Quality, Reliability and Scale

We combine certifications, process control and extensive testing to keep quality consistent—from first prototype to large-volume orders. You can start with a small NPI run and grow into mass production without changing suppliers or redesigning around new process limits.

If you are working on LED products—from simple indicator boards to high-power, networked lighting systems—APTPCB can support the LED PCB manufacturing, LED PCB assembly, and all related electronics in one integrated flow. Share your requirements with our team, and we’ll help you turn your design into a reliable, manufacturable product that performs the way your customers expect.