Choosing the right LED PCB is ultimately a thermal and materials decision, not just a question of copper traces and pad shapes. Junction temperature, substrate choice and stack-up all determine how bright, stable and long-lasting your LED product will be.

At APTPCB, we are a full-service PCB and PCBA manufacturer working with FR-4, high-Tg, HDI, flex, rigid-flex, metal core (MCPCB), ceramic and other advanced materials. LED PCBs are one of the key application areas where our experience in thermal design, stack-up engineering and mass production comes together.

Understanding LED PCB Manufacturing and Its Unique Challenges

LEDs have transformed lighting, displays and indicator functions across many industries. But for a PCB factory, LED PCBs are not a separate world – they are one of many application types that stress thermal performance, reliability and material choice.

High-power LEDs are particularly sensitive to junction temperature. If the PCB cannot move heat away efficiently, you see reduced light output, color shift, faster lumen depreciation and, in the worst case, early failure. In this sense, an LED PCB is both an electrical interconnect platform and a thermal path, very similar to what we design for power electronics, automotive control, RF power stages and other high-dissipation circuits.

At APTPCB, we are a full-service PCB and PCBA manufacturer. We work with FR-4, high-Tg, HDI, flex, rigid-flex, metal core (MCPCB), ceramic, high-frequency materials and more. LED PCBs are simply one of the many application scenarios where our stack-up design, thermal management and manufacturing experience come together.

Key Considerations in LED PCB Manufacturing

Thermal Management as a First-Class Design Goal

The PCB must conduct heat away from the LED junction into the housing or heatsink with as few thermal bottlenecks as possible. Depending on power level and cost targets, this may involve optimized copper areas, thermal vias, or dedicated metal core and high-thermal PCB solutions.Material Selection Across Multiple Platforms

Substrate choice drives both thermal and electrical behavior. For low-power or indicator LEDs, standard FR-4 may be sufficient; for high-power or harsh-environment designs, aluminum-based MCPCB, copper-based metal core, high-Tg FR-4 or ceramic substrates can be used – often within the same factory and process framework.Circuit Design and Layout for Current and Heat

The layout must provide stable current delivery and low voltage drop while also supporting clean thermal paths. Trace width, copper thickness, pad design and component placement all affect both electrical performance and junction temperature.Optical and Surface Considerations Where Needed

In some LED applications, PCB surface color and finish matter. White solder mask may be chosen to enhance reflection in lighting modules; dark solder mask may be used to reduce glare or match industrial design. These choices must remain compatible with the underlying materials and manufacturing processes.Reliability Under Thermal and Environmental Stress

Solder joints, dielectrics and interfaces must withstand thermal cycling, humidity, vibration and handling. Process control, stack-up design and qualification testing are key to long-term LED PCB reliability, just as they are for automotive, industrial or communication boards.Cost-Effectiveness and Scalability

LED projects span from small pilot runs to very high-volume production. The selected materials, panelization and processes need to be repeatable and cost-efficient while still meeting the electrical and thermal specifications. A general-purpose PCB factory can reuse its wider process toolbox to balance cost and performance.

LED PCBs as Part of a Broader PCB Capability

By treating LED PCBs as one member of a larger technology family – alongside power, RF, automotive, industrial control and communication boards – APTPCB can apply the same engineering discipline to stack-up definition, thermal design and manufacturability.

Whether your design uses standard FR-4, high-Tg, flex, rigid-flex, metal core or ceramic, our role is the same: translate your electrical and thermal requirements into a robust, producible PCB and, when needed, a complete PCBA solution. LED modules benefit from this broad capability, rather than being limited to a narrowly defined “LED-only” process.

Optimizing Performance from the Ground Up

By addressing these critical points early in the design and manufacturing process, APTPCB helps you avoid common pitfalls associated with LED products, such as premature dimming or failure. We leverage our expertise in PCB fabrication processes to create LED PCBs that are not only electrically sound but also thermally robust, leading to extended product life and consistent performance.

This proactive approach to LED PCB manufacturing ensures that your products meet performance specifications, reduce warranty claims, and ultimately enhance your brand's reputation for quality and reliability.

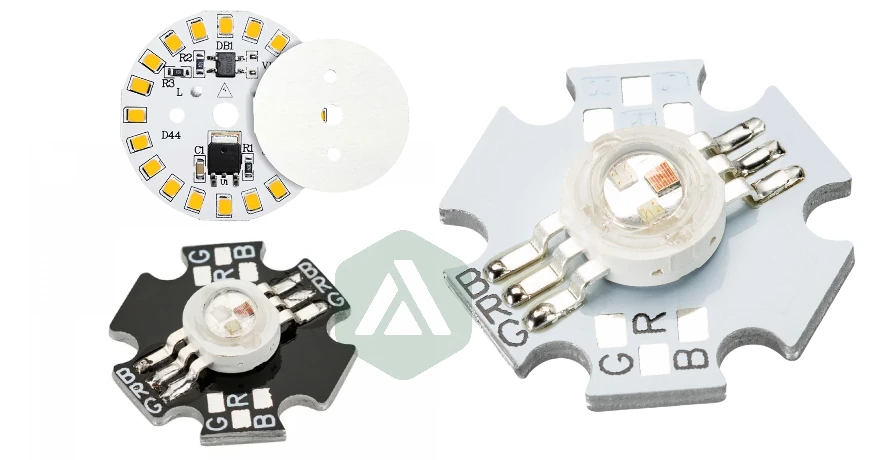

Practical LED PCB Manufacturing Examples and Material Choices

The world of LED PCBs is diverse, largely driven by the varying power levels and thermal demands of different LED applications. Choosing the right material and manufacturing approach is paramount. Here are some practical examples of LED PCB manufacturing and their typical material choices:

Key LED PCB Manufacturing Examples and Materials

FR-4 LED PCBs – Cost-Effective for Low Power Typical Use: Indicator lights, low-power displays, simple control boards. Materials: Standard FR-4 (fiberglass-reinforced epoxy laminate). Characteristics: Most common and economical. Suitable for applications where heat generation is minimal or external heat sinks are sufficient. Thermal vias can be used to improve heat transfer to the bottom side.

Metal Core PCBs (MCPCB) – The Thermal Workhorse Typical Use: High-power LED lighting (streetlights, automotive, architectural), LED backlights, industrial lighting. Materials: A dielectric layer laminated onto a metal base (typically aluminum or copper). Characteristics: MCPCBs are excellent for dissipating heat rapidly due to the high thermal conductivity of the metal core. They allow LEDs to operate at cooler temperatures, extending lifespan and maintaining brightness. They are available in single-layer, double-layer, and even multi-layer configurations.

Aluminum Core PCBs: The most common type of MCPCB, offering a good balance of thermal performance and cost.

Copper Core PCBs: Offer even higher thermal conductivity than aluminum but are more expensive and heavier. Used in extremely high-power applications where maximum heat dissipation is critical.

Ceramic PCBs – High Performance for Harsh Environments Typical Use: High-brightness LEDs, automotive headlamps, medical lighting, aerospace applications, chip-on-board (COB) LEDs. Materials: Aluminum Nitride (AlN), Alumina (Al2O3), Beryllium Oxide (BeO - less common due to toxicity). Characteristics: Ceramic PCBs offer superior thermal conductivity, excellent electrical insulation, and high-temperature resistance. They are often used for direct chip attachment (COB) due to their coefficient of thermal expansion (CTE) matching that of silicon, reducing stress on solder joints. They are more expensive but provide unparalleled performance in demanding conditions.

Flexible LED PCBs – For Dynamic Designs Typical Use: Wearable devices, flexible display backlights, contoured lighting strips, automotive interior lighting. Materials: Polyimide (PI) film with copper traces. Characteristics: Allow for bending and flexing, enabling innovative form factors for LED integration. While their thermal conductivity is lower than MCPCBs, clever design can manage heat for moderately powered flexible LED arrays.

Tailored Solutions for Every LED Application

At APTPCB, we don't just offer standard solutions; we work with you to analyze your specific LED application, thermal budget, power requirements, and environmental conditions. Our engineers guide you through the selection of the most appropriate advanced PCB manufacturing techniques and materials, ensuring that your LED PCB is optimized for both performance and cost.

By leveraging our extensive experience in LED PCB manufacturing, we help you overcome thermal challenges, enhance product reliability, and bring innovative LED designs to market efficiently.

Advanced Techniques in LED PCB Manufacturing for Superior Thermal Management

As LED power densities continue to increase, traditional thermal management solutions are often insufficient. Advanced LED PCB manufacturing techniques are crucial for pushing the boundaries of what's possible in terms of brightness, compactness, and longevity. These techniques often involve specialized materials and sophisticated fabrication processes aimed at maximizing heat dissipation.

Key Advanced Techniques in LED PCB Manufacturing

- Direct Thermal Path Design:

This involves creating the most direct and efficient path for heat from the LED junction to a heat sink or the ambient environment. This includes:

- Thermal Vias: Plated through-holes filled with thermally conductive material or simply left open to transfer heat from the top copper layer to a lower ground/thermal plane or a metal core.

- Thick Copper Layers: Using 2 oz, 3 oz, or even higher copper weights for signal and plane layers significantly improves thermal spreading and conduction.

- Wide Traces and Copper Pours: Maximizing copper area around LED pads helps spread heat laterally across the PCB.

- Specialized Dielectric Materials for MCPCBs: While aluminum is the common core, the dielectric layer between the copper circuit and the metal base is critical. Advanced MCPCBs use highly thermally conductive but electrically insulating dielectrics (e.g., epoxy resins loaded with ceramic fillers) to minimize thermal resistance.

- Embedded Heat Sinks or Heat Pipes: For extremely high-power applications, passive heat sinks or even miniature heat pipes can be directly embedded within the PCB structure during the manufacturing process, creating a highly integrated thermal solution.

- Copper Inlays and Coin Technology: This technique involves embedding a thick copper "coin" or slug directly under the LED component. This copper inlay creates a localized, ultra-low thermal resistance path from the LED to the bottom side of the PCB, where it can connect to an external heat sink.

- Chip-on-Board (COB) Manufacturing on Ceramic Substrates: COB LEDs directly mount the bare LED chip onto a substrate (often ceramic due to its thermal properties and CTE match). This eliminates the thermal resistance of a traditional LED package, providing a more direct thermal path. Ceramic PCBs excel here due to their inherent thermal conductivity and ability to withstand high processing temperatures.

- Advanced Lamination and Bonding: Precise control over lamination cycles and bonding materials is essential, especially for multi-layer MCPCBs or hybrid constructions, to ensure optimal thermal and electrical integrity.

Partnering for Next-Generation LED Solutions

APTPCB is at the forefront of implementing these advanced LED PCB manufacturing techniques. Our multi-layer laminated structures expertise, combined with our deep understanding of thermal physics and material science, enables us to tackle the most challenging LED projects.

When you collaborate with APTPCB, you gain access to:

- Expert Design for Manufacturability (DFM) Review: We analyze your LED layout for optimal thermal performance and manufacturability, suggesting improvements before production.

- Material Selection Guidance: Leveraging our relationships with leading material suppliers, we recommend the best dielectric and core materials for your specific thermal and electrical requirements.

- Precision Fabrication: Our state-of-the-art facilities and stringent PCB quality control ensure that even the most complex thermal management features are fabricated accurately and reliably.

If you're developing high-power, high-brightness, or compact LED solutions, send us your design specifications. Our engineering team will help you unlock the full potential of your LEDs through optimized LED PCB manufacturing.