Modern illumination systems have evolved far beyond simple on/off switches. Today, a Lighting Control PCB serves as the intelligent brain behind smart homes, automotive headlamps, and industrial grow lights. These circuit boards manage power distribution, execute complex logic protocols (like DALI or DMX), and ensure thermal stability for high-power LEDs.

For engineers and procurement managers, selecting the right specifications is critical. A failure in the control board can lead to flickering, color shifts, or catastrophic thermal runaway. At APTPCB (APTPCB PCB Factory), we see firsthand how subtle design choices impact the longevity of these systems. This guide covers the entire lifecycle of a lighting control board, from initial definition to mass production validation.

Key Takeaways

- Dual Functionality: A Lighting Control PCB often combines high-power management (LED driving) with low-voltage logic (microcontrollers).

- Thermal Priority: Heat dissipation is the primary failure mode; material selection (FR4 vs. Metal Core) is the most critical decision.

- Protocol Compliance: Designs must adhere to specific communication standards like Zigbee, DALI, or proprietary RF protocols.

- Environmental Stress: Boards must withstand humidity and vibration, similar to a Climate Control PCB used in HVAC systems.

- Validation: Automated Optical Inspection (AOI) is not enough; functional testing under load is mandatory.

What Lighting Control PCB really means (scope & boundaries)

Understanding the core takeaways helps us define the exact scope of these circuit boards. A Lighting Control PCB is not always the board holding the LEDs (the light engine); often, it is the separate driver or controller board that dictates behavior.

These boards bridge the gap between the raw power source and the light emitting diodes. They contain rectifiers, DC-DC converters, and microcontrollers (MCUs) that interpret user inputs or sensor data. In complex industrial setups, the reliability requirements for these boards mirror those of heavy machinery electronics, such as a Compactor Control PCB. Both must operate reliably in harsh environments where dust, vibration, and temperature fluctuations are constant.

The scope includes:

- LED Drivers: Constant current or constant voltage regulation.

- Smart Interfaces: Wi-Fi, Bluetooth, or wired control modules.

- Power Management: Surge protection and EMI filtering.

Metrics that matter (how to evaluate quality)

Once the scope is defined, you must quantify performance using specific manufacturing metrics. High-quality lighting controls rely on materials that can handle thermal stress and electrical noise.

| Metric | Why it matters | Typical Range / Factors | How to Measure |

|---|---|---|---|

| Thermal Conductivity | Determines how fast heat moves away from sensitive components (MOSFETs/drivers). | FR4: 0.3 W/mK MCPCB: 1.0 – 4.0+ W/mK |

ASTM D5470 or Laser Flash Method. |

| Glass Transition (Tg) | The temperature where the PCB base material begins to soften and expand. | Standard: 130°C High-Tg: >170°C (Recommended for high power). |

TMA (Thermomechanical Analysis). |

| CTI (Comparative Tracking Index) | Measures resistance to electrical breakdown (tracking) across the surface. | Level 0: >600V (Crucial for high-voltage mains inputs). | IEC 60112 Standard Test. |

| Copper Weight | Affects current carrying capacity and heat spreading. | Signal: 1oz (35µm) Power: 2oz–4oz (70µm–140µm). |

Micro-section analysis. |

| Dielectric Breakdown | The voltage at which the insulation layer fails. | >3kV AC is standard for safety compliance. | Hi-Pot Testing. |

Selection guidance by scenario (trade-offs)

With the metrics established, the next step is choosing the right PCB technology for your specific application. There is no "one size fits all" in lighting control; a smart bulb requires different technology than a stadium floodlight.

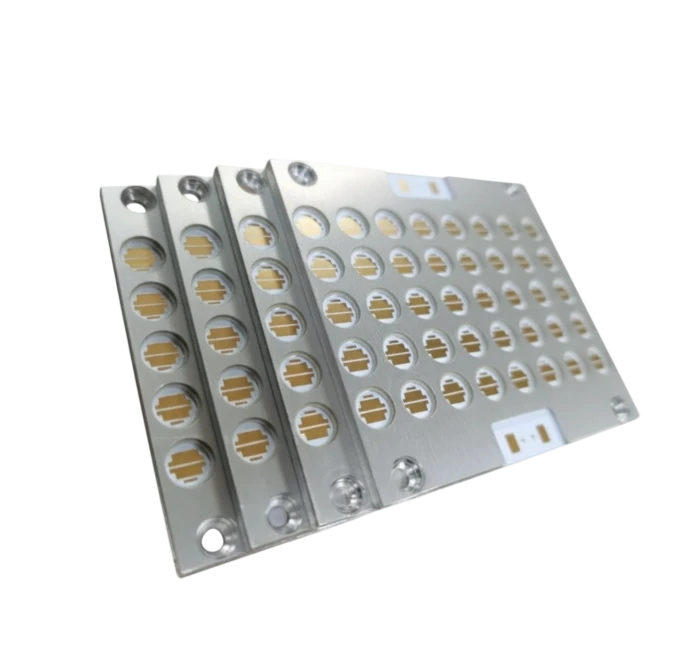

1. High-Power Industrial Lighting

- Scenario: Warehouse high-bays or streetlights.

- Recommendation: Metal Core PCB (MCPCB) with aluminum base.

- Trade-off: Higher cost than FR4, but essential for dissipating heat from high-wattage drivers without bulky heatsinks.

2. Smart Home IoT Bulbs

- Scenario: Wi-Fi enabled RGBW bulbs.

- Recommendation: High-Tg FR4 with thermal vias.

- Trade-off: Lower thermal conductivity than metal core, but allows for complex multilayer routing required by the Wi-Fi/Bluetooth MCU.

3. Automotive Headlamp Control

- Scenario: Adaptive LED matrix headlights.

- Recommendation: Ceramic PCB or Hybrid Rigid-Flex.

- Trade-off: Extremely expensive, but offers the highest reliability and thermal stability under engine hood temperatures.

4. Horticultural Lighting

- Scenario: Greenhouse grow lights.

- Recommendation: FR4 with heavy copper and conformal coating.

- Trade-off: Must resist high humidity. Similar to an Aeroponic Control PCB, the board requires robust protection against moisture ingress and fertilizer corrosion.

5. Heavy Machinery Illumination

- Scenario: Lights mounted on construction balers or crushers.

- Recommendation: Thick rigid boards with locking connectors.

- Trade-off: Focus is on vibration resistance. The design rules here align with a Baler Control PCB, prioritizing mechanical stability over miniaturization.

6. Architectural Strip Lighting

- Scenario: Curved cove lighting.

- Recommendation: Polyimide Flex PCB.

- Trade-off: Excellent flexibility but poor thermal dissipation. Requires mounting onto an external aluminum profile.

From design to manufacturing (implementation checkpoints)

After selecting the right material and technology, you must ensure the design is manufacturable. APTPCB recommends a structured checkpoint system to prevent delays during the NPI (New Product Introduction) phase.

- Schematic Validation: Ensure the LED driver IC matches the voltage forward (Vf) requirements of the LED string.

- Thermal Simulation: Run a thermal analysis. If the junction temperature exceeds 85°C, switch from FR4 to Metal Core or increase copper weight.

- Stackup Definition: Define the dielectric thickness clearly. For high-voltage controls, ensure the prepreg layers provide sufficient isolation.

- Component Placement: Keep sensitive analog control lines away from high-frequency switching nodes (DC-DC converters) to prevent flickering.

- Trace Width Calculation: Use IPC-2221 standards to calculate trace widths for the maximum current, adding a 20% safety margin.

- Solder Mask Selection: For boards reflecting light, use white solder mask with high reflectivity. For internal control boards, standard green or black is acceptable.

- DFM Review: Submit Gerber files for a DFM Guidelines check. Look for acid traps or slivers that could cause shorts.

- Panelization: Design the panel with V-cuts or mouse bites that do not stress the solder joints of ceramic capacitors near the edge.

- First Article Inspection (FAI): Always produce a small batch (5-10 units) to verify dimming curves and thermal performance before mass production.

- Conformal Coating Plan: Decide if the board needs acrylic or silicone coating based on the installation environment.

Common mistakes (and the correct approach)

Even with a solid plan, specific engineering pitfalls frequently occur in lighting control projects. Avoiding these errors saves time and reduces scrap rates.

- Mistake 1: Ignoring Inrush Current.

- Impact: Relays fuse together or traces blow upon startup.

- Correction: Include NTC thermistors or soft-start circuits in the power stage.

- Mistake 2: Poor Grounding Strategy.

- Impact: EMI issues causing the lights to strobe or interfere with other electronics.

- Correction: Separate power ground and signal ground, connecting them at a single star point.

- Mistake 3: Neglecting Creepage and Clearance.

- Impact: Arcing between high-voltage mains and low-voltage control logic.

- Correction: Follow UL/IEC standards strictly. Cut slots in the PCB if necessary to increase creepage distance.

- Mistake 4: Overlooking Signal Precision.

- Impact: Stepped or jittery dimming.

- Correction: Treat dimming signals like precision instruments. Similar to a Coagulation Control PCB used in medical diagnostics, lighting controls require clean, noise-free analog signals for smooth operation.

- Mistake 5: Wrong Surface Finish.

- Impact: Oxidation or poor wire bonding.

- Correction: Use ENIG (Electroless Nickel Immersion Gold) for flat surfaces and better corrosion resistance compared to HASL.

- Mistake 6: Underestimating Vibration.

- Impact: Solder fatigue in industrial environments.

- Correction: Add glue or staking to heavy capacitors, a technique standard in robust designs like a Compactor Control PCB.

FAQ

Q: Can I use standard FR4 for a 50W LED driver? A: It depends on the efficiency and cooling. If the driver is 95% efficient, it dissipates 2.5W. With thermal vias and a heatsink, FR4 is fine. Without airflow, you may need an aluminum PCB.

Q: What is the difference between DALI and DMX for PCB design? A: DALI is a two-wire, non-polarized system often used in building automation (slower). DMX is a high-speed differential signal (RS-485 based) used for stage lighting. DMX requires strict impedance matching (120 ohms) on the PCB.

Q: Why do my LEDs flicker at low dimming levels? A: This is often due to noise on the PWM signal line or an unstable power supply voltage at low loads. Improving the decoupling capacitors near the MCU usually helps.

Q: How do I specify the color of the PCB for lighting? A: Specify "White Taiyo PSR-4000" (or equivalent) in your fabrication notes if high reflectivity is needed. Note that white solder mask can discolor at high reflow temperatures if not processed correctly.

Q: Does APTPCB offer assembly for these boards? A: Yes, we provide Turnkey Assembly, handling both PCB fabrication and component sourcing/soldering.

Q: What is the best surface finish for wire bonding LEDs directly to the PCB? A: ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) is the gold standard for wire bonding reliability.

Q: How do you test for "thermal runaway"? A: We perform burn-in testing where the board is run at maximum power in an environmental chamber to ensure the temperature stabilizes within safe limits.

Q: Can you manufacture boards for specialized industrial controls? A: Yes, our capabilities extend beyond lighting to complex industrial units, including designs similar to a Climate Control PCB or other environmental regulation systems.

Glossary (key terms)

| Term | Definition |

|---|---|

| MCPCB | Metal Core Printed Circuit Board. A PCB with a base metal material (usually aluminum or copper) for heat spreading. |

| PWM | Pulse Width Modulation. A method used to dim LEDs by turning them on and off rapidly. |

| DALI | Digital Addressable Lighting Interface. A protocol for lighting control in buildings. |

| Junction Temperature (Tj) | The internal temperature of the LED chip. Exceeding this reduces lifespan. |

| TIM | Thermal Interface Material. Grease or pad placed between the PCB and heatsink. |

| CTE | Coefficient of Thermal Expansion. How much the material expands with heat. Mismatch causes cracks. |

| Creepage | The shortest distance between two conductive parts along the surface of the insulation. |

| Clearance | The shortest distance between two conductive parts through the air. |

| Driver | The circuit that converts mains voltage to the specific current/voltage required by the LED. |

| Blind Via | A via connecting an outer layer to an inner layer, not going through the entire board. |

| Fiducial Mark | A reference point on the PCB used by assembly machines for alignment. |

| Gerber File | The standard file format used to manufacture PCBs. |

Conclusion (next steps)

A successful Lighting Control PCB project requires balancing thermal management, signal integrity, and mechanical durability. Whether you are designing a sleek smart home device or a rugged industrial floodlight, the choices you make in materials and layout define the product's success.

At APTPCB, we specialize in turning complex lighting requirements into reliable hardware. From high-thermal MCPCBs to complex rigid-flex designs, our engineering team is ready to assist.

Ready to quote? Please provide the following for an accurate review:

- Gerber Files: RS-274X format.

- Stackup Details: Copper weight, dielectric thickness, and material type (FR4, Aluminum, etc.).

- Bill of Materials (BOM): If assembly is required.

- Special Requirements: White solder mask, specific CTI ratings, or functional test procedures.

Contact us today to start your DFM review and ensure your lighting control system shines brightly for years to come.