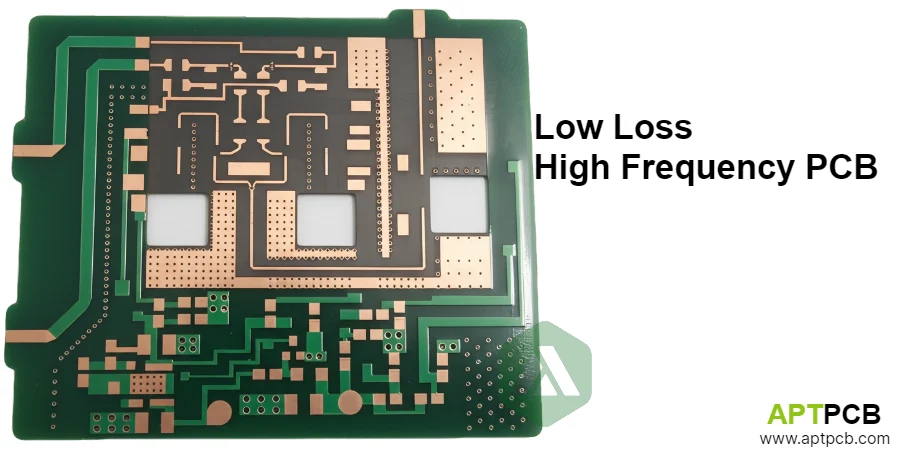

Low loss high frequency printed circuit boards represent critical technology enabling systems where signal attenuation must be minimized including satellite communications requiring maximum range, test equipment demanding measurement accuracy, and radar systems needing detection sensitivity. The pursuit of low loss performance drives material innovation, process refinement, and design optimization throughout high frequency PCB manufacturing.

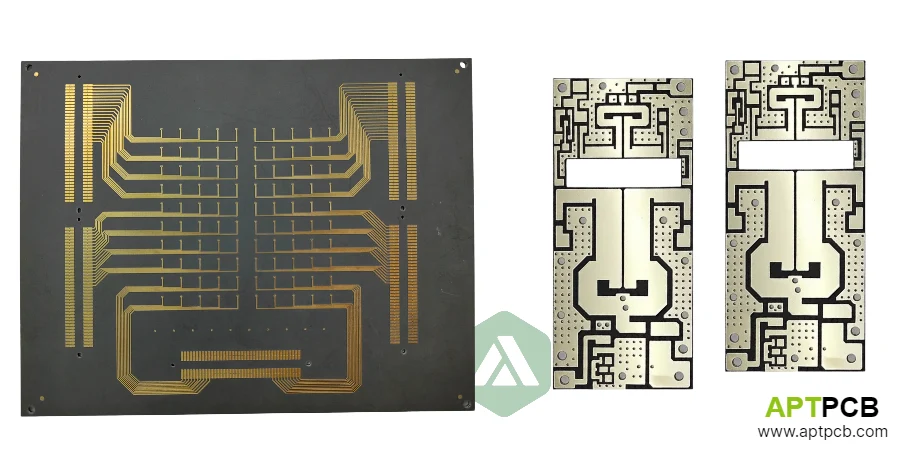

At APTPCB, we manufacture low loss high frequency PCBs with specialized expertise implementing ultra-low loss substrates, smooth copper technologies, and precision fabrication. Our capabilities support RF high frequency PCB applications demanding minimal signal attenuation with validated manufacturing processes ensuring consistent low loss performance.

Understanding Signal Loss Mechanisms

Signal loss in high frequency PCBs results from multiple mechanisms including dielectric absorption, conductor resistance, and radiation effects that together determine total insertion loss. Understanding each loss mechanism guides material selection, design optimization, and manufacturing process control. Inadequate loss understanding causes excessive signal attenuation limiting range, unexpected loss variations between channels, or inability to meet loss budget requirements — directly impacting system performance and design success.

At APTPCB, our manufacturing addresses all loss mechanisms for minimal total insertion loss.

Key Loss Mechanisms

- Dielectric Loss: Molecular polarization in substrate materials absorbing electromagnetic energy characterized by loss tangent (tan δ) increasing with frequency through material-specific mechanisms.

- Conductor Loss: Resistance from skin effect concentrating current near conductor surfaces with effective resistance increasing as skin depth decreases at higher frequencies.

- Surface Roughness Loss: Current following irregular conductor surfaces increasing path length and resistance particularly significant when roughness approaches skin depth dimensions.

- Radiation Loss: Electromagnetic energy escaping from microstrip and discontinuity structures into free space reducing transmitted signal power.

- Via Transition Loss: Resistive and reactive losses from via structures connecting layers including stub resonance effects at higher frequencies.

- Loss Budget Analysis: Systematic accounting of all loss contributors ensuring total insertion loss meets system requirements through testing quality verification.

Loss Mechanism Management

Through comprehensive understanding of loss mechanisms, appropriate material selection, and optimized fabrication processes coordinated with design requirements, APTPCB enables low loss PCBs meeting demanding insertion loss specifications.

Implementing Ultra-Low Loss Material Solutions

Low loss PCB performance fundamentally depends on substrate material selection with different materials offering vastly different dielectric loss characteristics. Material selection must balance loss performance against thermal properties, dimensional stability, cost, and manufacturing processability. Inadequate material selection causes excessive dielectric losses limiting achievable performance, thermal management challenges in power applications, or processing difficulties reducing yield — directly impacting product performance and manufacturing efficiency.

At APTPCB, our manufacturing implements comprehensive low loss material capabilities.

Key Material Technologies

- Standard PTFE Laminates: Glass-reinforced PTFE materials with loss tangent around 0.001 suitable for most microwave RF PCB applications providing excellent loss performance with proven processing.

- Ultra-Low Loss PTFE: Premium PTFE formulations achieving loss tangent below 0.0009 for demanding satellite and test equipment applications requiring minimum attenuation.

- Ceramic-Filled PTFE: Materials combining low loss characteristics with enhanced thermal conductivity supporting power amplifier applications through RF circuit board manufacturing thermal management.

- Advanced Hydrocarbon: Rogers RO4000 series and similar materials with loss tangent around 0.003-0.004 providing cost-effective low loss performance through 10 GHz.

- Ultra-Low Loss Specialty Materials: Emerging formulations achieving loss tangent below 0.001 through advanced polymer chemistry for extreme performance requirements.

- Material Characterization: Incoming verification of dielectric constant and loss tangent ensuring material properties meet design specifications.

Material Excellence

By implementing comprehensive material expertise, validated processing parameters, and application-appropriate selection guidance, APTPCB delivers low loss PCBs achieving target dielectric loss specifications across substrate technologies.

Optimizing Conductor Loss Performance

Conductor losses become increasingly significant at higher frequencies where skin effect concentrates current near conductor surfaces making surface characteristics critical. Smooth copper technologies and appropriate surface finishes minimize conductor loss contribution. Inadequate conductor optimization causes excessive resistive losses at higher frequencies, inconsistent loss between production lots, or degraded performance from inappropriate surface finishes — significantly impacting total insertion loss and system performance.

At APTPCB, our manufacturing implements conductor optimization for minimum loss.

Key Conductor Optimization Techniques

- Smooth Copper Foils: Rolled annealed and reverse-treated copper with minimized surface roughness reducing effective resistance where skin depth approaches roughness dimensions.

- Copper Weight Selection: Appropriate conductor thickness balancing current capacity with minimal benefit beyond several skin depths at operating frequency through high frequency PCB fabrication practices.

- Surface Finish Selection: Immersion silver or OSP finishes avoiding magnetic losses from nickel underlayers while providing adequate solderability for high frequency PCB assembly requirements.

- Plating Control: Electroplating processes maintaining surface quality without introducing roughness degrading high frequency performance.

- Oxide Treatment Selection: Alternative oxide treatments and bonding promoters avoiding surface roughening while ensuring lamination adhesion.

- Roughness Measurement: Surface characterization validating conductor roughness meets specifications with correlation to electrical loss performance.

Conductor Loss Excellence

Through smooth copper technologies, appropriate surface finish selection, and controlled processing coordinated with conductor loss requirements, APTPCB achieves conductor loss performance supporting demanding low loss applications.

Designing for Minimum Transmission Line Loss

Transmission line design significantly affects total insertion loss through configuration selection, length optimization, and transition management. Design decisions balance loss minimization against other circuit requirements. Inadequate transmission line design causes higher loss than necessary for given requirements, unequal loss between channels affecting balance, or excessive transitions increasing cumulative loss — directly impacting system loss budget and performance.

At APTPCB, our manufacturing supports optimized transmission line designs for minimum loss.

Key Design Optimization Strategies

- Stripline vs. Microstrip Selection: Stripline eliminating radiation loss for sensitive applications while microstrip provides component access with manageable radiation through controlled impedance high frequency PCB configurations.

- Length Minimization: Component placement optimizing for short high frequency paths reducing cumulative loss with multilayer routing enabling direct paths.

- Via Transition Reduction: Minimizing layer transitions reducing cumulative via losses with optimized transition structures where transitions required.

- Backdrilling Implementation: Via stub removal preventing resonance effects adding to insertion loss at higher frequencies through precision depth control.

- Trace Width Optimization: Impedance-matched trace widths maximizing conductor cross-section within impedance constraints reducing resistive loss.

- Coupling Management: Appropriate spacing preventing parasitic coupling adding loss while enabling intentional coupling where designed.

Design Optimization Support

By supporting optimized transmission line designs, providing DFM review, and enabling design features minimizing loss coordinated with fabrication capabilities, APTPCB enables low loss PCB implementations meeting demanding specifications.

Validating Low Loss Performance

Low loss PCB verification requires accurate loss characterization across operating frequency range with material property confirmation and transmission line measurement. Testing validates design predictions and manufacturing consistency. Inadequate validation misses loss performance issues, lacks data for design correlation, or fails to detect production variations — impacting product quality and design confidence.

At APTPCB, our testing provides comprehensive low loss verification.

Key Verification Capabilities

- Network Analyzer Measurement: Insertion loss measurement across frequency using calibrated test fixtures with de-embedding removing fixture contributions for accurate device characterization.

- Material Characterization: Dielectric constant and loss tangent verification using resonant or transmission line methods confirming substrate properties meet specifications.

- TDR Verification: Time domain reflectometry confirming impedance control contributing to low return loss and efficient power transfer.

- Test Coupon Design: Coupon structures accurately representing product transmission lines enabling production monitoring through high frequency PCB manufacturer quality practices.

- Statistical Analysis: Production coupon data analysis relating measurements to overall product performance with trend monitoring for process control.

- Loss Budget Correlation: Comparison of measured loss to design predictions validating models and identifying optimization opportunities.

Verification Excellence

Through comprehensive loss measurement, material characterization, and statistical analysis coordinated with quality requirements, APTPCB validates low loss PCB performance meeting customer specifications.

Supporting Critical Low Loss Applications

Low loss high frequency PCBs enable demanding applications where signal preservation is paramount including communications infrastructure, radar systems, and test equipment. Application-specific requirements guide material selection, design optimization, and verification approaches. Inadequate application understanding causes specifications not matching operational needs, inappropriate material selection, or insufficient verification — impacting product suitability and system performance.

At APTPCB, our manufacturing supports critical low loss applications.

Key Application Areas

Satellite Communications

- Antenna feed networks requiring efficient power delivery from HPAs to radiating elements through aerospace defense quality standards.

- Receiver front ends preserving weak signals through low loss RF paths for maximum sensitivity.

- Frequency conversion assemblies maintaining signal integrity through multiple stages.

- Phased array modules requiring consistent low loss across numerous identical channels.

Radar and Sensing Systems

- Transmit paths efficiently delivering power to antennas for maximum detection range.

- Receive paths preserving weak return signals for processing with minimum degradation.

- Phased array radar with low loss beam-forming networks across production volumes.

- Automotive radar at 77 GHz demanding low loss in cost-competitive high-volume production.

Test and Measurement

- Signal generator output networks delivering accurate levels through minimal loss paths.

- Network analyzer calibration standards with characterized, repeatable loss performance.

- Probe systems minimizing signal degradation for accurate device characterization.

Application Excellence

Through application understanding, appropriate manufacturing approaches, and quality systems meeting industry requirements, APTPCB delivers low loss PCBs serving demanding application needs across communications, radar, and test equipment markets.

Manufacturing for Consistent Low Loss

Achieving consistent low loss performance requires tight process control throughout fabrication maintaining material properties, dimensional accuracy, and surface characteristics determining loss. Statistical monitoring ensures production consistency. Inadequate process control causes lot-to-lot loss variations, individual board variations exceeding specifications, or drift over time requiring correction — impacting product consistency and customer satisfaction.

At APTPCB, our manufacturing implements precision control for consistent low loss.

Key Manufacturing Controls

- Dielectric Thickness Control: Lamination processes achieving consistent dielectric thickness affecting loss and impedance through high frequency multilayer PCB construction precision.

- Trace Width Accuracy: Precision etching maintaining trace widths within tolerance affecting conductor loss and impedance.

- Surface Roughness Control: Processing maintaining conductor surface characteristics throughout fabrication with measurement verification.

- Plating Uniformity: Copper plating achieving consistent thickness across panels maintaining uniform loss characteristics.

- Cleanliness Control: Contamination prevention avoiding surface effects that could degrade high frequency performance.

- Statistical Process Control: Parameter monitoring with control charts identifying variations before specification limits reached.

Manufacturing Consistency

Through precision process control, statistical monitoring, and continuous improvement supported by quality systems, APTPCB achieves manufacturing consistency delivering low loss PCBs meeting specifications reliably across production.