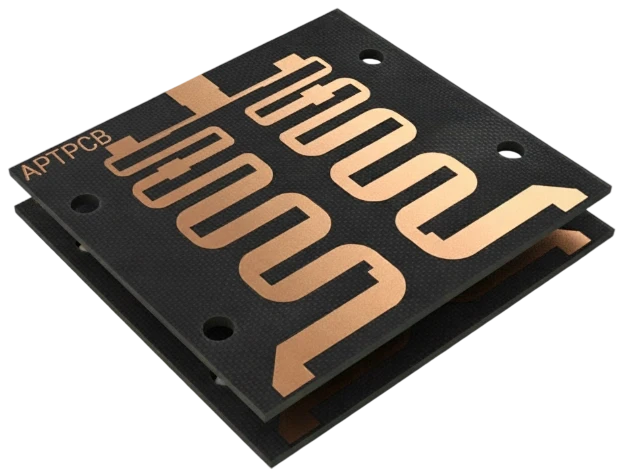

LTE-V2X PCB technology enables vehicle-to-everything communication, operating primarily in the 5.9 GHz ITS band to support safety-critical data exchange. Unlike standard automotive boards, these PCBs require high-frequency materials, precise impedance control, and strict adherence to automotive reliability standards like IPC-6012 Class 3. APTPCB (APTPCB PCB Factory) specializes in fabricating these hybrid structures, ensuring signal integrity for C-V2X and 5G V2X applications.

LTE-V2X PCB quick answer (30 seconds)

- Material Selection: Most designs utilize a hybrid stackup combining high-frequency laminates (e.g., Rogers RO4350B or RO3003) for signal layers with high-Tg FR4 for digital/power layers to balance cost and performance.

- Frequency Requirements: The board must support the 5.9 GHz band with low insertion loss; standard FR4 is typically insufficient for the RF path due to high dielectric loss.

- Impedance Control: Strict control (±5% to ±7%) is required for 50Ω single-ended and 100Ω differential pairs to prevent signal reflection.

- Automotive Reliability: Boards must pass thermal cycling tests (-40°C to +125°C or higher) and meet AEC-Q100/200 compatible board level reliability standards.

- Copper Roughness: Very Low Profile (VLP) or Hyper Very Low Profile (HVLP) copper foil is necessary to minimize skin effect losses at high frequencies.

- Via Technology: Blind, buried, and stacked vias are common to increase density, often requiring backdrilling to remove signal stubs that cause resonance.

When LTE-V2X PCB applies (and when it doesn’t)

Understanding the specific use case prevents over-engineering or under-specifying the circuit board.

Use LTE-V2X PCB when:

- Designing On-Board Units (OBU): The device handles direct vehicle-to-vehicle (V2V) or vehicle-to-infrastructure (V2I) communication.

- Developing Roadside Units (RSU): Infrastructure hardware that communicates with passing vehicles requires high-durability, weather-resistant RF boards.

- Integrating C-V2X Modules: The PCB hosts a cellular V2X modem requiring specific RF routing and thermal dissipation.

- High-Speed Data Aggregation: The system acts as a V2X Gateway PCB processing sensor fusion data (LiDAR, Radar, Camera) alongside V2X messages.

- 5G V2X Applications: Designs utilizing 5G NR (New Radio) sidelink interfaces requiring ultra-low latency.

Do not use LTE-V2X PCB when:

- Standard Body Control Modules: Door locks, window lifters, and seat controllers operate at low frequencies and should use standard FR4.

- Basic Infotainment (Non-Connected): Audio amplifiers or screens without integrated V2X connectivity do not need expensive high-frequency laminates.

- Low-Speed Diagnostics: OBD-II dongles that only read CAN bus data do not require RF-grade PCB fabrication.

- Cost-Sensitive Consumer Electronics: The materials and processes for V2X are significantly more expensive than standard consumer-grade PCBs.

LTE-V2X PCB rules and specifications (key parameters and limits)

Adhering to specific parameters ensures the board functions correctly in the 5.9 GHz spectrum while surviving the automotive environment.

| Rule / Parameter | Recommended Value / Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Dielectric Constant (Dk) | 3.0 – 3.6 (RF Layers) | Affects signal propagation speed and impedance dimensions. | TDR Testing / Material Datasheet | Impedance mismatch; signal reflection. |

| Dissipation Factor (Df) | < 0.003 @ 10 GHz | Determines signal loss (attenuation) as heat. | Vector Network Analyzer (VNA) | High insertion loss; reduced communication range. |

| Copper Roughness | < 2 µm (VLP/HVLP) | Reduces skin effect losses at 5.9 GHz. | SEM Analysis / Cross-section | Increased signal loss; thermal rise. |

| Impedance Tolerance | ±5% or ±7% | Ensures maximum power transfer. | TDR (Time Domain Reflectometry) | High VSWR; poor antenna performance. |

| Thermal Reliability | T260 > 60 min; T288 > 15 min | Withstands reflow and automotive operating temps. | TMA (Thermal Mechanical Analysis) | Delamination during assembly or field use. |

| Glass Transition (Tg) | > 170°C (High Tg) | Prevents barrel cracks during thermal expansion. | DSC (Differential Scanning Calorimetry) | Via failure in harsh environments. |

| Via Stub Length | < 10 mil (or Backdrilled) | Prevents resonant frequencies interfering with signals. | X-Ray / Cross-section | Signal distortion; bit error rate increases. |

| Solder Mask | LPI, specific Dk/Df matched | Standard mask can alter impedance on microstrips. | Impedance Coupon Testing | Impedance shifts on outer layers. |

| Cleanliness | < 1.56 µg/cm² NaCl eq. | Prevents electrochemical migration (ECM). | Ion Chromatography | Dendrite growth; short circuits. |

| Layer Registration | ± 3 mil | Critical for coupling in broadside coupled structures. | X-Ray Inspection | High crosstalk; impedance variation. |

LTE-V2X PCB implementation steps (process checkpoints)

Fabricating a V2X Communication PCB requires a modified process flow to handle hybrid materials and strict RF requirements.

Stackup Design & Simulation

- Action: Define the hybrid stackup (e.g., Rogers top layer, FR4 core). Simulate trace widths for 50Ω impedance.

- Key Parameter: Material compatibility (CTE matching between RF and FR4 materials).

- Check: Verify resin content is sufficient to fill voids in copper patterns without starving the laminate.

Material Preparation & Handling

- Action: Cut high-frequency laminates using specialized routing to prevent fraying.

- Key Parameter: Dimensional stability of PTFE or ceramic-filled hydrocarbons.

- Check: Ensure no debris or scratches on the dielectric surface before imaging.

Inner Layer Imaging & Etching

- Action: Apply compensation factors for etchback, which differs between standard copper and VLP copper.

- Key Parameter: Trace width tolerance (typically ±0.5 mil for RF lines).

- Check: Automated Optical Inspection (AOI) to detect "mouse bites" or protrusions on RF traces.

Hybrid Lamination

- Action: Press the heterogeneous materials using a cycle optimized for the material with the highest cure temperature/pressure requirement.

- Key Parameter: Heating ramp rate and cool-down cycle to minimize warpage.

- Check: Inspect for delamination or voids at the interface between dissimilar materials.

Drilling & Backdrilling

- Action: Drill vias with optimized feed/speed for ceramic-filled materials to reduce bit wear. Perform controlled depth drilling (backdrilling) on high-speed signal vias.

- Key Parameter: Stub length remaining (< 10 mil).

- Check: X-ray verification of backdrill depth relative to the target internal layer.

Plating & Surface Finish

- Action: Apply copper plating followed by a flat surface finish like ENIG or Immersion Silver. HASL is generally avoided due to unevenness.

- Key Parameter: Plating thickness uniformity (min 20-25 µm in hole).

- Check: Verify surface flatness for fine-pitch BGA components (often used in V2X modules).

Final Electrical Test

- Action: Perform 100% net list testing and TDR impedance testing on coupons.

- Key Parameter: Pass/Fail based on impedance tolerance (e.g., 50Ω ±5%).

- Check: Generate a TDR report confirming impedance values for all critical nets.

LTE-V2X PCB troubleshooting (failure modes and fixes)

Issues with V2X Antenna PCB or communication boards often manifest as signal degradation or reliability failures.

Symptom: High Insertion Loss (Signal Attenuation)

- Causes: Incorrect material Df, rough copper profile, or excessive solder mask coverage on RF lines.

- Checks: Review material datasheet vs. actual usage; inspect copper foil type (STD vs. VLP).

- Fix: Switch to VLP/HVLP copper; remove solder mask from RF traces (solder mask window).

- Prevention: Specify maximum roughness and Df in the fabrication notes.

Symptom: Impedance Mismatch (High VSWR)

- Causes: Over-etching of traces, variation in dielectric thickness, or incorrect reference plane distance.

- Checks: Cross-section analysis to measure actual trace width and dielectric height.

- Fix: Adjust trace width compensation in CAM; tighten press-out thickness tolerance.

- Prevention: Use "dummy copper" balancing to ensure even pressure during lamination.

Symptom: Delamination after Reflow

- Causes: Moisture absorption in materials, CTE mismatch between hybrid materials, or insufficient bonding.

- Checks: Check baking logs; analyze interface between FR4 and RF material.

- Fix: Bake boards before assembly; optimize lamination cycle for hybrid stacks.

- Prevention: Store moisture-sensitive materials in dry cabinets; select prepregs with compatible resin systems.

Symptom: Passive Intermodulation (PIM)

- Causes: Poor copper etching quality, contamination in the substrate, or ferromagnetic surface finishes (like HASL with high nickel).

- Checks: PIM testing; visual inspection for etch residue.

- Fix: Use Immersion Silver or ENIG (with controlled phosphorus); improve etch quality.

- Prevention: Design for PIM; avoid 90-degree corners on RF traces.

Symptom: CAF (Conductive Anodic Filament) Growth

- Causes: Electrochemical migration along glass fibers due to voltage bias and humidity.

- Checks: Insulation resistance testing under high humidity.

- Fix: Increase hole-to-hole clearance; use CAF-resistant materials.

- Prevention: Adhere to strict design rules for high-voltage or tight-pitch areas; use anti-CAF prepregs.

How to choose LTE-V2X PCB (design decisions and trade-offs)

Selecting the right approach for an LTE-V2X PCB involves balancing RF performance against cost and manufacturability.

Hybrid Stackup vs. Pure High-Frequency Material

- Hybrid (Recommended): Uses expensive RF material (e.g., Rogers) only for the outer signal layers and standard FR4 for the inner power/ground/digital layers. This significantly reduces material cost while maintaining RF performance.

- Pure RF Material: Uses high-frequency laminate for the entire board. This offers the best consistency and thermal stability but is 3-5x more expensive. Use only for extremely critical military or aerospace V2X applications.

Surface Finish: ENIG vs. Immersion Silver

- ENIG (Electroless Nickel Immersion Gold): Excellent shelf life and solderability. However, the nickel layer can cause slight signal loss at very high frequencies due to magnetic properties.

- Immersion Silver: Better for RF performance (no nickel) and lower cost, but has a shorter shelf life and is sensitive to tarnishing. Choose Silver for pure performance; choose ENIG for reliability and shelf life.

Ceramic-Filled vs. Non-Ceramic PTFE

- Ceramic-Filled: Easier to process (drill/plate) and more dimensionally stable. Preferred for complex multilayer V2X boards.

- Non-Ceramic PTFE: Lower loss but very difficult to process (requires special hole preparation). Avoid unless ultra-low loss is the only priority.

LTE-V2X PCB FAQ (cost, lead time, common defects, acceptance criteria, Design for Manufacturability (DFM) files)

What drives the cost of an LTE-V2X PCB? The primary cost driver is the high-frequency laminate material (Rogers, Taconic, Isola), which can be 5-10x the price of FR4. Other factors include hybrid lamination complexity, backdrilling requirements, and strict impedance testing (Class 3).

What is the typical lead time for these boards? Standard lead time is 10-15 working days. However, high-frequency materials often have longer procurement lead times. APTPCB recommends checking material stock during the quoting phase.

Do I need backdrilling for V2X PCBs? If your signal frequency is 5.9 GHz and you have through-hole vias connecting top-to-inner layers, the remaining "stub" can cause resonance. Backdrilling is highly recommended for any via stub longer than 10-15 mils on RF lines.

What are the acceptance criteria for automotive V2X PCBs? Most automotive customers require adherence to IPC-6012 Class 3 (High Reliability). This mandates stricter plating thickness (average 25µm), no breakout allowed on vias, and rigorous thermal stress testing.

Can I use standard FR4 for 5.9 GHz V2X? Generally, no. Standard FR4 has a high Dissipation Factor (Df ~0.02), which results in excessive signal loss and phase distortion at 5.9 GHz. Specialized "High-Speed FR4" (like Megtron 6) or RF laminates are required.

What files are needed for a DFM review? Provide Gerber files (RS-274X), a detailed stackup drawing specifying material types (e.g., "Rogers RO4350B 10mil"), drill files (NC Drill), and an IPC-356 netlist for electrical test verification.

How do you test V2X Antenna PCBs? Beyond standard E-test (Open/Short), we perform TDR (Time Domain Reflectometry) for impedance, and optionally VNA (Vector Network Analyzer) testing for insertion loss if specified.

What is the difference between C-V2X and DSRC PCB requirements? Both operate near 5.9 GHz, so material requirements are similar. However, C-V2X (Cellular V2X) often requires more complex integration with cellular bands (4G/5G), leading to higher density HDI designs compared to DSRC.

How does APTPCB handle hybrid material CTE mismatch? We use optimized lamination cycles with controlled heating and cooling rates. We also assist in stackup design to ensure the construction is balanced to prevent warping.

Is IATF 16949 certification required? For automotive production parts, the manufacturing facility must be IATF 16949 certified. APTPCB ensures compliance with automotive quality management systems.

Resources for LTE-V2X PCB (related pages and tools)

- Automotive Electronics PCB: Explore our capabilities in manufacturing high-reliability automotive boards.

- High Frequency PCB: Details on RF materials, processing, and signal integrity for 5.9 GHz applications.

- Rogers PCB Materials: Specific data on Rogers laminates commonly used in V2X stackups.

- HDI PCB Technology: For complex C-V2X modules requiring microvias and high-density routing.

- Impedance Calculator: Estimate trace width and spacing for your 50Ω and 100Ω lines.

LTE-V2X PCB glossary (key terms)

| Term | Definition | Context in PCB |

|---|---|---|

| C-V2X | Cellular Vehicle-to-Everything | Communication standard using cellular technology (4G LTE/5G). |

| DSRC | Dedicated Short-Range Communications | Older WiFi-based V2X standard (802.11p). |

| ITS Band | Intelligent Transportation Systems Band | The 5.9 GHz frequency spectrum reserved for V2X. |

| Hybrid Stackup | Mixed Material Build | Combining RF material and FR4 in one board to save cost. |

| Backdrilling | Controlled Depth Drilling | Removing the unused portion of a plated through-hole (stub). |

| Skin Effect | Current Crowding | Tendency of AC current to flow near the surface of the conductor at high frequencies. |

| Insertion Loss | Signal Attenuation | The loss of signal power resulting from insertion of a device (trace) in a transmission line. |

| OBU | On-Board Unit | The V2X device installed inside the vehicle. |

| RSU | Roadside Unit | The V2X infrastructure device installed on traffic lights/poles. |

| MIMO | Multiple Input Multiple Output | Antenna technology using multiple transmitters/receivers; requires precise PCB routing. |

Request a quote for LTE-V2X PCB (Design for Manufacturability (DFM) review + pricing)

For accurate pricing and a comprehensive DFM review, please submit your design data to APTPCB. We specialize in hybrid stackups and automotive-grade reliability.

Please include the following for a fast response:

- Gerber Files: RS-274X format preferred.

- Stackup Drawing: Specify RF material type (e.g., Rogers, Isola) and layer order.

- Fabrication Notes: Include IPC class (Class 2 or 3), copper weight, and surface finish.

- Volume: Prototype quantity vs. estimated production volume.

Conclusion (next steps)

Successfully deploying an LTE-V2X PCB requires navigating the complexities of high-frequency materials, hybrid lamination, and strict automotive reliability standards. By selecting the right stackup and partnering with a capable manufacturer, you ensure your OBU or RSU performs reliably in the 5.9 GHz ITS band. APTPCB provides the engineering support and manufacturing precision needed to bring these safety-critical designs to the road.