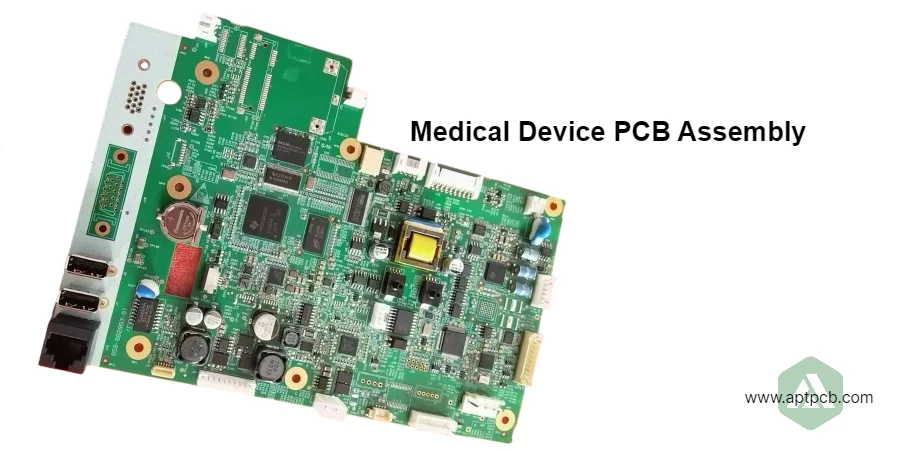

Medical device PCB assemblies implement patient monitoring, diagnostic equipment, and therapeutic systems requiring ISO 13485 quality management, IEC 60601 electrical safety, biocompatible materials, and FDA regulatory compliance supporting vital signs monitors, diagnostic imaging, infusion pumps, and surgical instruments demanding validated manufacturing, comprehensive testing, and complete traceability through 10-15 year product lifecycles with zero-tolerance for failures impacting patient safety.

At APTPCB, we deliver medical device assembly services with medical devices expertise implementing ISO 13485 certified processes and validated manufacturing supporting Class I through Class III medical devices.

Achieving ISO 13485 and FDA Compliance

Medical device manufacturing requires ISO 13485 quality management system, FDA Design Controls (21 CFR Part 820), and comprehensive documentation supporting regulatory submissions and audits. Regulatory challenges include process validation (IQ/OQ/PQ), design history files, device master records, and change control. Inadequate compliance prevents FDA clearance, causes audit findings requiring corrective actions, or results in warning letters impacting business — significantly affecting market access, product launches, and regulatory standing.

At APTPCB, our assembly implements ISO 13485 certified processes achieving FDA compliance and audit readiness.

Regulatory Compliance Implementation

- ISO 13485 Quality System: Certified processes covering design controls, process validation, and risk management with quality system documentation.

- Process Validation: IQ/OQ/PQ protocols validating manufacturing processes meet specifications with documented evidence supporting regulatory submissions.

- Design History File Support: Comprehensive documentation tracking design inputs, verification, validation, and risk management activities.

- Traceability Systems: Lot tracking, serial numbering, and test result recording enabling complete device genealogy from components through final shipment.

- Change Control: Rigorous change management with impact assessment, validation, and documentation maintaining regulatory compliance.

- Audit Support: Hosting FDA, notified body, or customer audits demonstrating compliance and facilitating regulatory approvals.

FDA Clearance Support

Through ISO 13485 certification, validated processes, and comprehensive documentation expertise, APTPCB enables medical device manufacturers achieving FDA 510(k) clearance, CE marking, and global regulatory approvals supporting market introduction.

Ensuring IEC 60601 Electrical Safety

Medical devices contacting or near patients require IEC 60601-1 electrical safety including reinforced isolation (4kV), leakage current limits (<100μA patient contact), and comprehensive protection against electrical hazards. Safety challenges include achieving adequate creepage/clearance distances, validating isolation barriers, and implementing protective earth or double insulation. Inadequate safety implementation prevents certification, creates patient shock hazards, or causes field safety incidents — significantly impacting patient safety, product liability, and regulatory compliance.

At APTPCB, our manufacturing implements IEC 60601 electrical safety achieving patient protection and regulatory compliance.

Electrical Safety Implementation

- Reinforced Isolation Design: >8mm creepage/clearance between patient connections and mains power meeting IEC 60601-1 requirements with testing quality validation.

- Leakage Current Control: Circuit design and component selection limiting earth leakage, enclosure leakage, and patient leakage currents below safety limits.

- Means of Protection: Type BF or CF isolation for patient-applied parts providing appropriate protection based on application risk.

- Protective Earth Integrity: Low-resistance (<0.1Ω) protective earth connections with monitoring and fault indication where required.

- Hipot Testing: Production testing applying 2x working voltage + 1000V validating insulation integrity on every unit.

- EMC Compliance: IEC 60601-1-2 EMC testing ensuring devices neither emit interference affecting other equipment nor are susceptible to external EMI.

Patient Safety Assurance

Through IEC 60601 expertise, validated electrical safety design, and comprehensive testing protocols, APTPCB delivers medical devices meeting electrical safety requirements protecting patients and clinical staff while achieving regulatory certification.

Implementing Biocompatible Materials and Coatings

Medical devices contacting skin or body fluids require biocompatible materials meeting ISO 10993 preventing cytotoxicity, sensitization, or irritation. Biocompatibility challenges include material selection, coating validation, and comprehensive testing demonstrating safety. Inadequate biocompatibility causes adverse patient reactions, regulatory compliance failures, or product recalls — significantly impacting patient safety and market access.

At APTPCB, our manufacturing implements biocompatible processes supporting body-contacting medical devices.

Biocompatibility Implementation

- Material Selection: Biocompatible PCB laminates, medical-grade conformal coatings, and appropriate surface finishes meeting ISO 10993 with PCB conformal coating expertise.

- Coating Validation: Parylene or medical-grade urethane coatings providing complete encapsulation preventing tissue contact with electronics.

- ISO 10993 Testing: Cytotoxicity, sensitization, irritation, and systemic toxicity testing validating material safety for intended patient contact.

- Cleaning Validation: Validated cleaning processes removing flux residues and contaminants ensuring biocompatibility and preventing contamination.

- Manufacturing Environment: Controlled assembly areas maintaining cleanliness standards preventing particulate contamination of medical devices.

Biocompatible Medical Devices

Through biocompatible material selection, validated coating processes, and ISO 10993 testing coordinated with clean assembly environments, APTPCB enables medical devices safe for patient contact supporting surgical instruments, monitors, and therapeutic applications.

Providing Precision Analog and Physiological Measurement

Medical devices measure vital signs (ECG, SpO2, blood pressure, temperature) requiring precision analog front-ends, low-noise design, and clinical accuracy validation. Measurement challenges include rejecting motion artifacts, preventing 50/60Hz interference, and achieving clinical correlation. Inadequate measurement implementation causes inaccurate readings affecting clinical decisions, false alarms causing notification fatigue, or regulatory compliance failures — significantly impacting clinical utility and patient safety.

At APTPCB, our assembly supports precision medical measurement achieving clinical accuracy specifications.

Medical Measurement Implementation

- Low-Noise Analog Design: High-resolution ADCs (16-24 bit), precision amplifiers, and proper grounding achieving >80dB SNR for biopotential signals.

- Motion Artifact Rejection: Adaptive filtering and signal processing algorithms maintaining measurement accuracy despite patient movement.

- Isolation and Protection: Medical-grade isolation amplifiers and defibrillator protection circuits ensuring patient safety and device survival.

- Clinical Accuracy Validation: Correlation studies comparing device measurements against gold-standard medical equipment validating accuracy specifications.

- FDA Recognized Standards: Design per AAMI standards (EC13 for ECG, EC57 for pulse oximetry) supporting regulatory submissions.

Through precision analog design and clinical validation coordinated with functional testing expertise, APTPCB enables medical devices achieving clinical-grade measurement accuracy supporting critical patient monitoring and diagnostic applications.

Supporting Sterile and Single-Use Devices

Surgical instruments and disposable medical devices require designs supporting sterilization (autoclave, ETO, radiation) or single-use construction meeting cost targets while maintaining performance and safety. Sterilization challenges include component and material selection surviving sterilization cycles, maintaining electrical performance post-sterilization, and achieving cost targets for disposables. Inadequate sterilization compatibility causes device failures post-sterilization, limits sterilization options, or requires expensive rework — significantly impacting product viability and hospital adoption.

At APTPCB, we support sterile medical device manufacturing with sterilization-compatible designs and cost-optimized assembly.

Sterile Device Support

Sterilization Compatibility

- Component selection surviving multiple autoclave, ETO, or gamma irradiation cycles without degradation.

- Material validation confirming PCB laminates, coatings, and adhesives maintain properties post-sterilization.

- Validation testing demonstrating electrical and mechanical performance unchanged after specified sterilization cycles.

Single-Use Optimization

- Cost-optimized designs achieving disposable device pricing while maintaining safety and performance requirements.

- Simplified assembly processes reducing manufacturing costs enabling single-use business models.

- Packaging and sterile barrier systems maintaining sterility through distribution and storage.

Through sterilization expertise and cost-conscious design coordinated with special PCB manufacturing capabilities, APTPCB enables both reusable and single-use medical devices meeting clinical requirements and economic targets.

Ensuring Complete Traceability and Quality Records

Medical device regulations require complete traceability from raw materials through patient use enabling recall management, complaint investigation, and continuous improvement. Traceability challenges include managing component lots, serial number assignment, and test result archiving. Inadequate traceability prevents effective recalls, complicates failure investigations, or results in regulatory findings — significantly impacting quality management and regulatory compliance.

At APTPCB, our manufacturing provides comprehensive traceability supporting medical device quality requirements.

Traceability Implementation

- Component Lot Tracking: Recording component lots used in each device enabling targeted recalls and supplier quality management.

- Serial Number Control: Unique device identification enabling individual device history tracking throughout lifecycle.

- Test Result Archiving: Permanent records of all electrical tests, inspections, and validations performed on each unit.

- Electronic Device History: Database systems linking components, processes, tests, and calibrations to specific devices.

- Complaint Handling: Investigation procedures linking field issues to manufacturing records supporting root cause analysis.

Through comprehensive traceability systems and quality documentation coordinated with incoming quality control processes, APTPCB enables medical device manufacturers meeting regulatory requirements and supporting quality management throughout device lifecycles.