Microinverter PCB assemblies enable module-level power optimization converting DC power from individual solar panels to AC grid voltage, requiring compact high-density designs withstanding outdoor exposure while maintaining >96% efficiency. Unlike central inverters managing entire arrays, microinverters must achieve exceptional power density fitting beneath solar panels while providing 25-year reliability matching panel warranties in harsh environmental conditions.

At APTPCB, we deliver specialized microinverter assembly services combining compact PCB designs, thermal management, environmental protection, and comprehensive testing. Our capabilities support residential and commercial module-level power electronics optimizing energy harvest from individual panels.

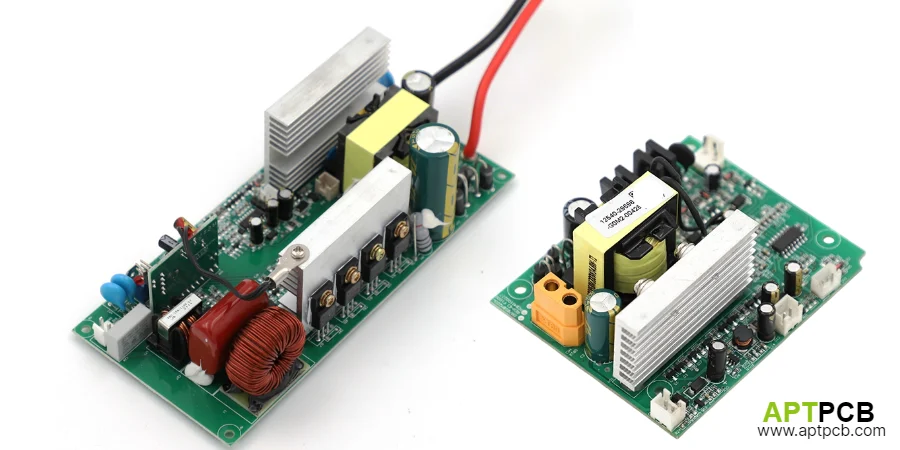

Implementing High-Density PCB Assembly for Compact Microinverters

Microinverter size constraints require high-density component placement and multilayer PCB construction fitting power conversion, control, and communication within limited enclosure volumes. Excessive size increases costs and mounting complexity while inadequate power density compromises efficiency or thermal performance.

At APTPCB, our assembly expertise optimizes component density without compromising reliability or manufacturability.

Key High-Density Assembly Techniques

- Fine-Pitch Component Placement: BGA QFN assembly handling 0.4mm pitch control ICs, power modules, and microprocessors with precision placement ensuring reliable connections.

- HDI PCB Integration: HDI PCB technology with microvias and fine-line routing enabling compact layouts and reduced layer counts optimizing cost and size.

- Component Height Management: Strategic component selection and placement maintaining low profile fitting compact enclosures while accommodating required heat sinks and cooling.

- Thermal Via Integration: Dense thermal via arrays beneath power devices transferring heat through PCB to chassis mounting surfaces within limited board area.

- High-Frequency Layout: Controlled impedance routing and proper grounding managing high-frequency switching noise in dense layouts preventing EMI issues.

- Assembly Process Validation: SMT assembly process optimization with reflow profiling and inspection ensuring reliable assembly of dense boards.

Compact Yet Reliable Design

Through high-density assembly expertise and advanced manufacturing, APTPCB delivers microinverter assemblies achieving power densities >100W/in³ while maintaining reliability and thermal performance.

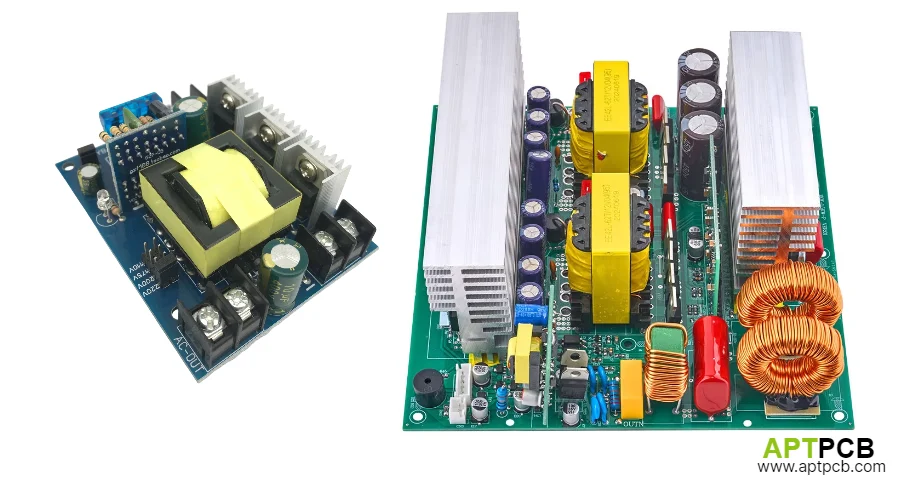

Managing Thermal Performance in Sealed Outdoor Enclosures

Microinverters operate in sealed weatherproof enclosures beneath solar panels experiencing elevated ambient temperatures from panel heating and direct sunlight. Inadequate thermal management causes efficiency loss, premature component failure, or safety shutdown reducing energy production and system reliability.

APTPCB implements comprehensive thermal strategies for sealed enclosure applications.

Key Thermal Management Strategies

- Optimized Copper Distribution: Heavy copper PCB construction with 2-4oz layers spreading heat from power semiconductors across board area reducing peak temperatures.

- Chassis Heat Transfer: PCB mounting and thermal interface design conducting heat from board to aluminum enclosure enabling convective and radiative cooling to ambient.

- Component Power Dissipation: Strategic placement of heat-generating devices maximizing thermal coupling to mounting surfaces and minimizing temperature rise.

- Thermal Simulation: Pre-production modeling validating thermal performance under worst-case conditions (high ambient, full power, no wind) ensuring specifications met.

- Material Selection: High-Tg materials maintaining performance during continuous elevated temperature operation in sealed enclosures.

- Thermal Testing Validation: Temperature measurement and thermal imaging during power testing verifying designs maintain safe operating temperatures.

Reliable Outdoor Operation

By combining thermal design with validated manufacturing, APTPCB enables microinverters achieving >96% efficiency while maintaining junction temperatures within specifications during full-power operation in 65°C ambient beneath panels.

Providing Environmental Protection for 25-Year Lifetimes

Microinverters require enhanced environmental protection surviving decades of moisture, temperature cycling, and potential condensation in sealed outdoor enclosures. Inadequate protection causes corrosion, insulation resistance degradation, or solder joint failures requiring warranty replacements.

APTPCB implements comprehensive environmental protection processes.

Key Protection Implementation Methods

- Conformal Coating Application: PCB conformal coating with acrylic or silicone materials providing moisture barriers while maintaining thermal dissipation and rework capability.

- Enhanced Surface Finishes: ENIG finish providing superior corrosion resistance compared to HASL ensuring long-term solder joint reliability and wire bond integrity.

- Cleaning and Contamination Control: Stringent flux removal and ionic contamination testing ensuring high insulation resistance in high-humidity outdoor environments.

- Moisture-Resistant Components: Component selection emphasizing sealed packages and moisture-insensitive materials surviving condensation and humidity exposure.

- Environmental Testing: Accelerated humidity, temperature cycling, and salt spray testing validating 25-year lifetime predictions in outdoor installations.

- Sealing and Potting: Optional potting materials for highest-reliability applications providing maximum environmental protection in extreme climates.

Decades of Field Reliability

Through comprehensive environmental protection and quality systems, APTPCB delivers microinverter assemblies achieving field failure rates <0.5% annually supporting 25-year warranties.

Executing Comprehensive Functional Testing for Microinverters

Microinverter validation requires testing efficiency, MPPT performance, grid synchronization, and protection circuits under realistic operating conditions. Inadequate testing results in field failures, efficiency losses, or safety non-compliance requiring expensive warranty service.

APTPCB provides dedicated microinverter test capabilities.

Key Functional Testing Requirements

- Efficiency Mapping: Testing across input voltage and power ranges verifying >96% peak efficiency and California Energy Commission (CEC) weighted efficiency compliance.

- MPPT Algorithm Validation: Simulating varying irradiance conditions testing maximum power point tracking speed and accuracy optimizing energy harvest.

- Grid Synchronization: Validating voltage/frequency tracking, power factor control, and anti-islanding protection meeting IEEE 1547 and UL 1741 requirements.

- Communication Testing: Verifying powerline communication (PLC), WiFi, or Zigbee monitoring interfaces ensuring reliable system monitoring and data collection.

- Protection Circuit Verification: Testing overvoltage, overcurrent, ground fault, and arc fault detection ensuring proper protective response.

- Environmental Stress Screening: Functional testing with temperature cycling and burn-in identifying early failures before shipment.

Validated Performance and Compliance

Through comprehensive testing with AOI inspection, APTPCB delivers microinverter assemblies meeting efficiency, safety, and reliability specifications.

Supporting Rapid Innovation in Microinverter Technology

Microinverter markets evolve rapidly with efficiency improvements, new power levels, and enhanced monitoring features requiring manufacturers adapting designs quickly. Manufacturing partners must support rapid development cycles, responsive engineering, and efficient volume production.

APTPCB provides agile manufacturing enabling microinverter innovation.

Key Development Support Capabilities

- Quick Turn Prototyping: NPI assembly delivering functional prototypes in 7-10 days supporting design validation and certification testing.

- DFM Optimization: Design review identifying assembly challenges, cost reduction opportunities, and reliability improvements before production commitment.

- Test Development: Custom fixture design and programming automating functional validation during production ramps and volume manufacturing.

- Component Engineering: Component sourcing expertise recommending alternates, managing obsolescence, and ensuring authentic parts from authorized distributors.

- Volume Transition: Smooth scaling from engineering builds through mass production maintaining consistent quality and processes.

- Technical Support: Engineering assistance throughout development, production launch, and volume manufacturing phases.

Accelerated Product Development

Through flexible manufacturing and support services, APTPCB enables microinverter manufacturers rapidly bringing new products to market supporting innovation and deployment.

Enabling Cost-Effective Volume Production

Microinverter competitiveness requires achieving target costs while maintaining quality and reliability. Manufacturing optimization must reduce costs without compromising the 25-year operational lifetime required for residential installations.

APTPCB implements cost optimization strategies balanced with reliability requirements.

Key Cost Optimization Approaches

- Panel Utilization Optimization: Efficient PCB profiling and panelization maximizing boards per panel reducing per-unit material costs.

- Component Standardization: Strategic component selection minimizing unique parts and leveraging high-volume purchasing for cost reduction.

- Process Efficiency: Automated assembly processes and optimized workflows reducing labor costs while maintaining quality consistency.

- Supply Chain Management: Volume purchasing, vendor-managed inventory, and strategic sourcing reducing component costs and ensuring availability.

- Design for Manufacturing: Collaborative optimization reducing layer counts, minimizing special processes, and improving assembly yield.

- Quality Cost Balance: Appropriate testing levels ensuring reliability while avoiding excessive costs from over-testing.

Competitive Manufacturing Economics

By combining efficiency with mass production capability, APTPCB delivers microinverter assemblies at competitive costs supporting market success.