The rapid electrification of the automotive industry has placed On-board charger PCB design at the center of vehicle performance and safety. As the critical bridge between the AC power grid and the high-voltage DC battery pack, the On-board Charger (OBC) must handle immense power loads while maintaining strict isolation and thermal stability. For engineers and procurement managers, understanding the nuances of this specific PCB category is no longer optional—it is a requirement for success in the EV market.

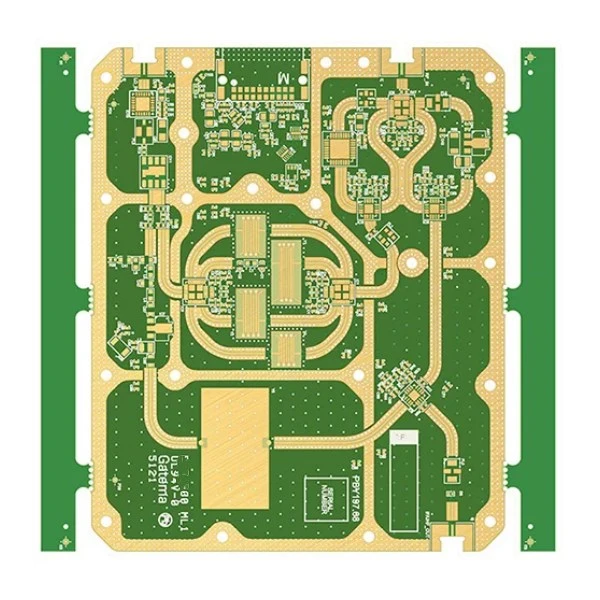

At APTPCB (APTPCB PCB Factory), we have witnessed the evolution of charging technology from simple low-power circuits to complex, bi-directional systems using wide-bandgap semiconductors. This guide serves as a comprehensive resource to navigate the complexities of designing, selecting, and manufacturing PCBs for on-board chargers.

Key Takeaways

- Definition: On-board charger PCB design focuses on converting grid AC to battery DC within the vehicle, prioritizing power density, thermal management, and high-voltage safety.

- Critical Metric: Efficiency is paramount; a 1% loss in a 22kW charger generates significant heat that the PCB layout must dissipate.

- Material Necessity: High CTI (Comparative Tracking Index) materials and heavy copper are standard requirements to prevent arcing and handle high currents.

- Misconception: Treating an OBC PCB like a standard power supply is dangerous; automotive vibration and temperature cycling require far more robust mechanical design.

- Validation: Automated Optical Inspection (AOI) is not enough; In-Circuit Testing (ICT) and Hi-Pot (High Potential) testing are mandatory for safety.

- Trend: The shift toward 800V architectures and Gallium Nitride (GaN) components demands tighter layout tolerances and advanced stackups.

What On-board charger PCB design really means (scope & boundaries)

To understand the specific requirements of On-board charger PCB design, we must first define its operational environment and functional scope compared to standard electronics. An OBC is not merely a power converter; it is a safety-critical automotive component that operates under harsh conditions while managing kilowatts of energy.

The scope of this design discipline encompasses three main stages:

- AC Input and PFC (Power Factor Correction): The PCB must handle grid voltage (110V-240V AC) and rectify it. This area requires robust EMI filtering and surge protection.

- DC-DC Conversion: This stage steps up or steps down the voltage to match the battery pack (400V or 800V). It involves high-frequency switching, often utilizing SiC or GaN MOSFETs, which require low-inductance PCB layouts.

- Control and Communication: The "brain" of the charger communicates with the Battery Management System (BMS) and the charging station (EVSE). This low-voltage section must be galvanically isolated from the high-voltage power stages to protect the vehicle's digital logic.

Unlike stationary industrial chargers, an On-board charger PCB travels with the vehicle. It is subjected to constant mechanical vibration, shock, and temperature extremes ranging from -40°C to +105°C (or higher). Therefore, the design is not just about electrical connectivity; it is about electro-mechanical reliability.

On-board charger PCB design metrics that matter (how to evaluate quality)

Once the scope of the On-board charger PCB design is defined, the next step is to establish quantifiable metrics to evaluate the quality and performance of the board. These metrics help engineers and buyers align on specifications before manufacturing begins.

| Metric | Why it matters | Typical range or influencing factors | How to measure |

|---|---|---|---|

| Thermal Conductivity | Determines how fast heat moves away from power components (MOSFETs, transformers). | 1.0 – 3.0 W/mK for FR4; >2.0 W/mK for MCPCB. | ASTM D5470 or Laser Flash Analysis. |

| CTI (Comparative Tracking Index) | Critical for preventing electrical breakdown (tracking) across the PCB surface under high voltage. | PLC 0 (600V+) or PLC 1 (400V-599V). | IEC 60112 standard tracking test. |

| Copper Weight | Dictates the current carrying capacity without excessive temperature rise. | 2oz to 6oz (Heavy Copper) is standard. | Micro-section analysis (cross-section). |

| Dielectric Breakdown Voltage | Ensures the insulation layer does not fail under high voltage spikes. | >3kV to 5kV depending on isolation requirements. | Hi-Pot test (High Potential). |

| Warpage / Bow & Twist | Flatness is essential for the reliable soldering of large power modules and heatsink attachment. | <0.75% (Standard), <0.5% (High reliability). | Shadow Moiré or laser profilometry. |

| Impedance Control | Vital for the CAN bus or communication lines talking to the BMS. | ±10% tolerance on differential pairs. | TDR (Time Domain Reflectometry). |

How to choose On-board charger PCB design: selection guidance by scenario (trade-offs)

Understanding the metrics allows us to apply On-board charger PCB design principles to specific automotive scenarios, where trade-offs between cost, performance, and space are inevitable. Different EV architectures require distinct PCB strategies.

Scenario 1: The Standard Commuter (3.3kW - 6.6kW OBC)

- Requirement: Cost-effective, moderate reliability.

- Solution: Standard FR4 High-Tg material with 2oz-3oz copper.

- Trade-off: Lower power density requires a larger board area for cooling.

- Best Practice: Use thermal vias extensively to transfer heat to the chassis.

Scenario 2: The Performance EV (11kW - 22kW OBC)

- Requirement: High power density, fast charging.

- Solution: Heavy Copper PCB (4oz+) or Metal Core PCB (MCPCB) for power stages.

- Trade-off: Higher manufacturing cost and heavier weight.

- Best Practice: Implement embedded copper coins or busbars for main current paths to reduce resistance.

Scenario 3: 800V Architecture (Next-Gen Fast Charging)

- Requirement: Extreme voltage isolation, high efficiency.

- Solution: Specialized materials with CTI >600V (PLC 0). Increased creepage distances.

- Trade-off: Layout becomes larger due to required safety spacing (clearance/creepage).

- Best Practice: Use conformal coating or potting to allow tighter spacing where physics permits.

Scenario 4: Bi-directional Charging (V2G - Vehicle to Grid)

- Requirement: Complex control logic, power flow in both directions.

- Solution: Multilayer PCB (6-10 layers) with mixed signal separation.

- Trade-off: Signal integrity becomes harder to manage due to switching noise from both directions.

- Best Practice: Strict separation of analog, digital, and power grounds.

Scenario 5: Space-Constrained Compact EVs

- Requirement: Fitting the charger into tight, irregular spaces.

- Solution: Rigid-Flex PCB technology to fold the circuit around mechanical housings.

- Trade-off: Significantly higher cost and complex assembly.

- Best Practice: Ensure the bend radius is calculated correctly to avoid trace cracking under vibration.

Scenario 6: High-Frequency GaN/SiC Chargers

- Requirement: Very fast switching speeds to reduce inductor size.

- Solution: Low-loss laminate materials (similar to RF boards) to minimize switching losses.

- Trade-off: Material cost is 2-3x higher than standard FR4.

- Best Practice: Minimize loop inductance in the layout to prevent voltage spikes that can destroy expensive switches.

On-board charger PCB design implementation checkpoints (design to manufacturing)

After selecting the right scenario, the On-board charger PCB design moves into the implementation phase, where theoretical designs are converted into physical manufacturing data. This phase is fraught with potential errors if specific checkpoints are not validated.

At APTPCB, we recommend the following checklist before releasing files for production:

Stackup Verification:

- Recommendation: Ensure the resin content in the prepreg is sufficient to fill the gaps between heavy copper tracks.

- Risk: Resin starvation leads to voids and delamination (measling).

- Acceptance: Review stackup simulation with the CAM engineer.

Creepage and Clearance Audit:

- Recommendation: Follow IPC-2221B or IEC 60664 standards for high voltage spacing.

- Risk: Arcing during operation, leading to catastrophic failure.

- Acceptance: Run a DFM (Design for Manufacturing) check specifically for net-to-net spacing on HV lines.

Thermal Via Design:

- Recommendation: Use plugged and capped vias (VIPPO) if placing vias in pads, or tented vias for isolation.

- Risk: Solder wicking away from the pad, resulting in poor thermal connection.

- Acceptance: Specify IPC-4761 Type VII for filled vias in the fabrication notes.

Heavy Copper Etching Compensation:

- Recommendation: Design traces slightly wider than the final requirement to account for etch-back.

- Risk: Traces becoming too thin to carry the required current.

- Acceptance: Consult the Automotive Electronics PCB guidelines for etch factors based on copper weight.

Solder Mask Quality:

- Recommendation: Use high-quality, high-voltage rated solder mask. Ensure dams between pads are sufficient.

- Risk: Solder bridging and reduced dielectric strength.

- Acceptance: Verify minimum solder dam width (typically 4mil for green, higher for other colors).

Component Placement for Assembly:

- Recommendation: Keep heavy components (chokes, capacitors) away from the board edges to reduce stress during depanelization.

- Risk: Ceramic capacitor cracking (MLCC) due to board flexing.

- Acceptance: Perform a stress analysis or follow strict keep-out zones.

Surface Finish Selection:

- Recommendation: ENIG (Electroless Nickel Immersion Gold) or Immersion Silver for flat pads.

- Risk: HASL is too uneven for fine-pitch components or large power modules.

- Acceptance: Visual inspection for planarization.

Panelization Strategy:

- Recommendation: Use robust waste tabs and mouse bites that can support the weight of a heavy copper board.

- Risk: Panel sagging during reflow, causing component misalignment.

- Acceptance: Review panel drawing for structural integrity.

On-board charger PCB design common mistakes (and the correct approach)

Even with a rigorous checklist, engineers often encounter pitfalls in On-board charger PCB design that only become apparent during testing or mass production. Identifying these early saves significant time and capital.

Mistake 1: Ignoring the "Skin Effect" in High-Frequency Tracks.

- Issue: At high switching frequencies (e.g., 100kHz+), current flows only on the outer surface of the conductor, increasing effective resistance.

- Correction: Use multiple thinner parallel layers or litz wire connections instead of just relying on a single thick trace for high-frequency AC currents.

Mistake 2: Underestimating Thermal Expansion (CTE Mismatch).

- Issue: Aluminum heatsinks and FR4 PCBs expand at different rates, stressing solder joints.

- Correction: Use materials with matched CTE or employ flexible thermal interface materials (TIM) that absorb the movement.

Mistake 3: Poor Grounding Strategy.

- Issue: Mixing high-power grounds with sensitive analog control grounds creates noise that disrupts the BMS communication.

- Correction: Use a "star ground" topology or dedicated ground planes, connecting them at a single point (usually near the ADC or controller).

Mistake 4: Over-reliance on Thermal Vias without Solder Control.

- Issue: Placing open vias under the thermal pad of a MOSFET sucks solder to the back of the board.

- Correction: Always tent vias on the bottom or use filled-and-capped vias to keep the solder on the pad.

Mistake 5: Neglecting Mechanical Supports for Heavy Components.

- Issue: Relying solely on solder joints to hold heavy inductors. Vibration will eventually crack the joint.

- Correction: Use RTV silicone or mechanical brackets/screws for large magnetic components.

Mistake 6: Inadequate Testing Coverage.

- Issue: Relying only on visual inspection.

- Correction: Implement rigorous PCB Quality protocols, including In-Circuit Test (ICT) and functional load testing.

On-board charger PCB design FAQ (cost, lead time, On-Board Charger PCB IPC-2221 (DESIGN) for Manufacturability (DFM) files, stackup, impedance, Automated Optical Inspection (AOI) inspection)

Q1: What is the difference between an On-board Charger (OBC) and a DC Fast Charger? The OBC is built inside the car and converts AC (grid) to DC. A DC Fast Charger is an external station that converts AC to DC outside the car and bypasses the OBC to charge the battery directly.

Q2: Why is heavy copper preferred for On-board charger PCB design? Heavy copper (3oz-6oz) allows the PCB to carry high currents (30A-60A+) with minimal resistive loss and heat generation, which is crucial for efficiency.

Q3: Can I use standard FR4 for an OBC? For low-power sections (control logic), yes. However, for the power stage, you typically need High-Tg (Glass Transition Temperature) FR4 or specialized high-CTI laminates to handle the thermal and voltage stress.

Q4: What is the typical voltage rating for an OBC PCB? Most modern EVs use a 400V battery architecture, requiring components rated for 600V-650V. Newer 800V architectures require PCBs and components rated for 1000V-1200V.

Q5: How do I manage heat in a sealed OBC unit? Heat management relies on transferring heat from components through the PCB (via thermal vias) to a liquid-cooled cold plate attached to the bottom of the board.

Q6: What is V2G and how does it affect PCB design? Vehicle-to-Grid (V2G) allows the car to send power back to the grid. This requires bi-directional switches and more complex filtering on the PCB, increasing the component count and layout density.

Q7: Is conformal coating necessary? Yes. Because the OBC is located in the vehicle, it is exposed to humidity and condensation. Conformal coating protects the high-voltage traces from shorting due to moisture.

Q8: What IPC standards apply to OBCs? IPC-6012 (Class 3 for automotive reliability), IPC-2221 (Design), and IPC-A-610 (Assembly acceptability) are the baselines.

Q9: How does switching frequency affect the PCB layout? Higher frequencies (using GaN/SiC) reduce the size of magnetics but increase EMI. The layout must minimize loop areas to prevent the PCB from becoming an antenna.

Q10: What data do I need to send for a quote? Gerber files, BOM (Bill of Materials), Pick & Place file, and a detailed fabrication drawing specifying copper weight, stackup, and special requirements like CTI or breakdown voltage.

Resources for On-board charger PCB design (related pages and tools)

- Automotive Electronics PCB: Explore our specific capabilities for the automotive sector.

- Heavy Copper PCB: Learn more about the manufacturing process for high-current boards.

- Turnkey Assembly Services: From PCB fabrication to component sourcing and final assembly.

- PCB Quality Control: Understand how we validate reliability through certifications and testing.

On-board charger PCB design glossary (key terms)

| Term | Definition |

|---|---|

| OBC | On-board Charger. The device inside an EV that converts AC grid power to DC battery power. |

| PFC | Power Factor Correction. A circuit stage that aligns voltage and current waveforms to maximize efficiency. |

| BMS | Battery Management System. The electronic system that manages a rechargeable battery (cell balancing, monitoring). |

| EMI / EMC | Electromagnetic Interference / Compatibility. Noise generated by switching circuits that must be contained. |

| CTI | Comparative Tracking Index. A measure of the electrical breakdown (tracking) properties of an insulating material. |

| Creepage | The shortest distance between two conductive parts along the surface of the insulation. |

| Clearance | The shortest distance between two conductive parts through the air. |

| Galvanic Isolation | Isolating functional sections of electrical systems to prevent current flow; no direct conduction path. |

| SiC | Silicon Carbide. A wide-bandgap semiconductor material used for high-voltage, high-efficiency switching. |

| GaN | Gallium Nitride. A semiconductor material allowing for very high switching frequencies and power density. |

| Tg | Glass Transition Temperature. The temperature at which the PCB base material turns from rigid to soft/deformable. |

| V2G | Vehicle-to-Grid. Technology enabling EVs to push energy back into the power grid. |

| EVSE | Electric Vehicle Supply Equipment. The external charging station or wall box. |

| Hi-Pot Test | High Potential Test. Verifies the insulation capability of the PCB/Assembly under high voltage. |

Conclusion (next steps)

On-board charger PCB design is a discipline that tolerates no shortcuts. It sits at the intersection of high-power electrical engineering, thermal dynamics, and automotive safety standards. A successful design requires a holistic approach—balancing efficiency metrics with robust material selection and rigorous manufacturing protocols.

Whether you are prototyping a next-generation GaN charger or scaling up production for a fleet of commercial EVs, the quality of the bare board determines the reliability of the final product.

Ready to move from design to production? When submitting your data to APTPCB for a DFM review or quote, please ensure you provide:

- Gerber Files (RS-274X format).

- Stackup Specifications (including copper weight and dielectric requirements).

- Fabrication Drawing (noting CTI requirements, solder mask type, and tolerance).

- Test Requirements (Hi-Pot voltage levels, impedance constraints).

By partnering with an experienced manufacturer early in the design phase, you ensure your On-board charger meets the rigorous demands of the modern road.