Key Takeaways

- Definition: An Optical Module PCB is the internal circuit board of a transceiver (like SFP, QSFP, or OSFP) responsible for converting electrical signals to optical signals and vice versa.

- Critical Metrics: Signal integrity (insertion loss, return loss) and thermal management are the two non-negotiable performance indicators.

- Material Selection: Standard FR4 is rarely sufficient; high-speed materials like Megtron 6/7 or Rogers are required for 100G, 400G, and 800G applications.

- Manufacturing Complexity: These boards often require HDI technology, rigid-flex structures, and precise wire bonding pads (gold fingers).

- Validation: Testing goes beyond standard electrical connectivity to include impedance control, thermal cycling, and high-frequency signal analysis.

- Integration: The form factor must fit strictly defined standards to plug into a 1U Server PCB or 2U Server PCB faceplate without mechanical interference.

What Optical Module PCB really means (scope & boundaries)

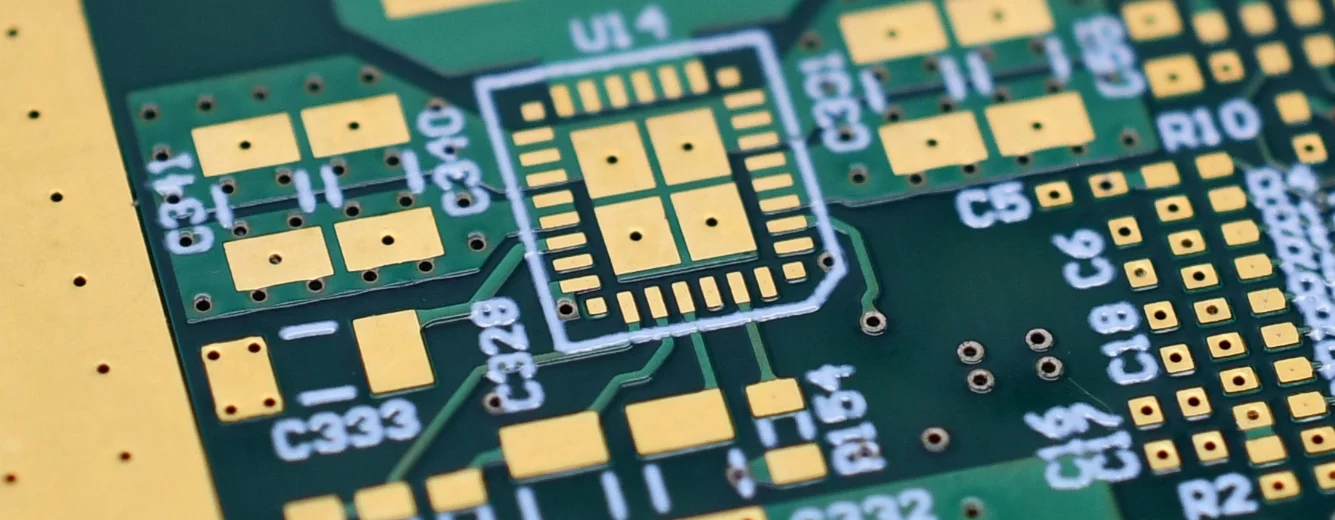

Before diving into technical specs, we must define exactly what constitutes an optical module board and where its boundaries lie. An Optical Module PCB is the miniaturized substrate housed inside optical transceivers. It acts as the bridge between the host system (switch, router, or server) and the optical components (TOSA/ROSA).

Unlike a standard motherboard, this PCB operates in a highly constrained space with extreme signal speed requirements. The scope of this technology covers various form factors, including SFP+, QSFP28, QSFP-DD, and OSFP. The primary function is to support the driver ICs, clock data recovery (CDR) chips, and the electro-optical interface.

The boundary of this definition excludes the main switch board or the backplane. It specifically refers to the pluggable unit's internal circuitry. APTPCB (APTPCB PCB Factory) specializes in these high-precision boards, distinguishing them from standard consumer electronics PCBs due to their stringent linewidth, spacing, and material requirements.

Optical Module PCB metrics that matter (how to evaluate quality)

Once the scope is defined, the next step is quantifying performance through specific metrics that determine signal fidelity and reliability.

| Metric | Why it matters | Typical Range / Factors | How to measure |

|---|---|---|---|

| Insertion Loss | Determines how much signal strength is lost as it travels through the PCB trace. Critical for long-reach modules. | < 0.5 dB/inch @ 14GHz (varies by material). | Vector Network Analyzer (VNA). |

| Dielectric Constant (Dk) | Affects signal propagation speed and impedance. Lower Dk is better for high speed. | 3.0 – 3.7 (High-speed materials). | Material datasheet / TDR testing. |

| Dissipation Factor (Df) | Represents energy lost as heat in the dielectric. Lower Df preserves signal integrity. | 0.002 – 0.005 (Ultra-low loss). | Material datasheet / Resonator method. |

| Thermal Conductivity | Optical lasers generate significant heat; the PCB must dissipate this to prevent wavelength drift. | 0.5 – 2.0 W/mK (or higher with metal cores). | Laser flash method / Thermal imaging. |

| Impedance Control | Mismatched impedance causes signal reflection (return loss), corrupting data. | 85Ω or 100Ω differential ±5%. | Time Domain Reflectometry (TDR). |

| Surface Roughness | Rough copper creates a "skin effect" resistance at high frequencies, increasing loss. | HVLP (Hyper Very Low Profile) copper foil. | Profilometer / SEM analysis. |

How to choose Optical Module PCB: selection guidance by scenario (trade-offs)

Understanding these metrics allows engineers to make informed decisions based on specific deployment scenarios, balancing cost against performance.

1. 10G / 25G SFP+ Modules (Cost-Sensitive)

For lower-speed modules used in enterprise access networks, standard high-Tg FR4 materials may suffice. The trade-off here favors cost over ultra-low loss. The design is typically a simple 4-6 layer rigid board.

- Choice: Mid-loss material, standard copper profile.

2. 100G QSFP28 Data Center Interconnects (Balanced)

This is the workhorse of modern data centers. You need materials like Panasonic Megtron 6 or Isola I-Speed. Standard FR4 will cause too much attenuation.

- Choice: Low-loss material, strict impedance control, HDI level 1.

3. 400G / 800G QSFP-DD (Performance-Critical)

At these speeds, signal margins are razor-thin. You must use ultra-low loss materials (e.g., Megtron 7/8, Rogers RO3003). Any impedance discontinuity is fatal to the link.

- Choice: Ultra-low loss material, HVLP copper, backdrilling, advanced HDI (2+N+2).

4. Silicon Photonics (High Integration)

Silicon photonics modules often require the PCB to act as an interposer. This scenario demands high-density interconnects (HDI) with fine pitch BGA support.

- Choice: Any-layer HDI, fine lines/spaces (3/3 mil or less).

5. 5G Fronthaul / Outdoor Telecom (Harsh Environment)

Modules installed in towers face extreme temperature swings. The PCB must have a CTE (Coefficient of Thermal Expansion) matched to the components to prevent solder joint cracking.

- Choice: High-reliability materials, robust surface finishes (ENEPIG).

6. High-Density Server Environments

When populating a 1U Server PCB or 2U Server PCB faceplate, thermal crosstalk becomes a major issue. The optical module PCB must have optimized thermal paths (thermal vias, coin embedding) to shed heat away from the laser diode.

- Choice: High thermal conductivity prepregs, embedded copper coins.

Optical Module PCB implementation checkpoints (design to manufacturing)

After selecting the right approach for your scenario, the focus shifts to the rigorous checkpoints required during design and manufacturing to ensure yield and performance.

Stackup Design & Material Verification

- Recommendation: Simulate the stackup using field solvers before layout. Confirm material availability with APTPCB.

- Risk: Incorrect dielectric thickness leads to impedance failure.

- Acceptance: Approved stackup sheet with calculated impedance.

High-Speed Trace Routing

- Recommendation: Use curved traces or 45-degree bends. Avoid stubs.

- Risk: Signal reflection and EMI issues.

- Acceptance: Simulation report showing acceptable return loss.

Via Design (Backdrilling)

- Recommendation: Implement backdrilling for through-hole vias on high-speed lines to remove unused stubs.

- Risk: Via stubs act as antennas, causing resonance.

- Acceptance: Cross-section analysis confirming stub removal depth.

HDI Structure Implementation

- Recommendation: Use staggered microvias for better reliability than stacked vias if space permits.

- Risk: Microvia failure during thermal cycling.

- Acceptance: Interconnect Stress Test (IST) results.

Surface Finish Selection

- Recommendation: Use ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) for wire bonding capability and solderability. Hard gold is needed for the edge connector fingers.

- Risk: Black pad syndrome (ENIG) or poor wire bond strength.

- Acceptance: Wire pull test and shear test.

Gold Finger Plating

- Recommendation: Ensure hard gold thickness is sufficient (typically >30 micro-inches) for repeated plugging.

- Risk: Contact wear leading to connection failure.

- Acceptance: X-ray thickness measurement.

Thermal Management Layout

- Recommendation: Place thermal vias directly under hot components (laser driver, DSP).

- Risk: Overheating causes laser wavelength drift or module shutdown.

- Acceptance: Thermal simulation and IR camera verification on prototype.

Glass Weave Mitigation

- Recommendation: Rotate the design 10 degrees or use "spread glass" styles (1067, 1078) to avoid skew.

- Risk: Fiber weave effect causes timing skew between differential pairs.

- Acceptance: Eye diagram analysis.

Solder Mask Registration

- Recommendation: Use Laser Direct Imaging (LDI) for precise mask alignment on small pads.

- Risk: Solder mask on pads prevents soldering; exposed traces cause shorts.

- Acceptance: Visual inspection (AOI).

Impedance Testing (TDR)

- Recommendation: Include test coupons on the panel panel border.

- Risk: Batch failure due to etching variations.

- Acceptance: TDR report showing impedance within ±5% or ±10%.

Optical Module PCB common mistakes (and the correct approach)

Even with a robust implementation plan, specific pitfalls often derail optical module projects. Avoiding these errors saves costly respins.

Mistake 1: Ignoring the "Fiber Weave Effect."

- Issue: At 25Gbps+, the gap between glass bundles in the PCB material causes signals to travel at different speeds on the P and N lines of a differential pair.

- Correction: Use Spread Glass FR4 or rotate the routing angle relative to the weave.

Mistake 2: Incorrect Surface Finish for Wire Bonding.

- Issue: Using standard ENIG for gold wire bonding often leads to weak bonds because the gold layer is too thin or the nickel is oxidized.

- Correction: Specify ENEPIG or Soft Gold for areas requiring wire bonding to the optical sub-assembly.

Mistake 3: Overlooking Pad Definition (SMD vs. NSMD).

- Issue: For fine-pitch BGAs inside the module, mixing Solder Mask Defined (SMD) and Non-Solder Mask Defined (NSMD) pads can cause stress fractures.

- Correction: Follow the component manufacturer's strict guidelines, usually favoring NSMD for better copper adhesion.

Mistake 4: Poor Thermal Path for the Laser.

- Issue: Relying solely on the casing for heat dissipation.

- Correction: Design a direct copper path (coin or dense via farm) from the laser diode pad through the PCB to the module shell.

Mistake 5: Underestimating Edge Connector Tolerances.

- Issue: If the PCB thickness or finger chamfer is out of spec, the module won't fit into the cage of a 1U Server PCB.

- Correction: Strictly control the overall thickness (including plating) and chamfer angle (usually 20° or 30°).

Mistake 6: Neglecting Stub Length in Vias.

- Issue: Leaving long via stubs on high-speed lines creates notch filters that kill specific frequencies.

- Correction: Mandate backdrilling for any via stub longer than 10-15 mils on high-speed nets.

Optical Module PCB FAQ (cost, lead time, materials, testing, acceptance criteria)

To address lingering uncertainties beyond common mistakes, here are answers to frequent questions regarding optical module boards.

Q: What are the primary cost drivers for Optical Module PCBs? A: The main drivers are the high-frequency laminate materials (Rogers/Megtron), the use of HDI (blind/buried vias), hard gold plating for edge connectors, and ENEPIG surface finishes.

Q: How does the lead time for Optical Module PCBs compare to standard boards? A: Due to complex lamination cycles (for HDI) and specialized plating processes, lead times are typically longer—often 15 to 20 days for prototypes, compared to 3-5 days for standard boards.

Q: Which materials are best for 800G optical modules? A: For 800G, you generally need ultra-low loss materials like Panasonic Megtron 7 or 8, or Rogers RO3003/RO4000 series. Standard "High-Speed" FR4 is usually insufficient. See our High Frequency PCB capabilities for more details.

Q: What specific testing is required for the gold fingers on these modules? A: Beyond electrical testing, gold fingers require thickness measurement (X-ray), adhesion testing (tape test), and porosity testing to ensure they can withstand repeated insertion cycles.

Q: Can rigid-flex technology be used in optical modules? A: Yes. Rigid-Flex PCB designs are increasingly common in compact modules (like QSFP-DD) to fold the circuitry and fit more components into the small enclosure without using connectors.

Q: What is the acceptance criteria for impedance control on these boards? A: Standard PCBs accept ±10%. However, for optical modules running at 25Gbps per lane or higher, a tolerance of ±5% or even ±7% is often required to maintain signal integrity.

Q: How do you handle heat dissipation in such a small PCB? A: We use heavy copper, thermal via farms, and sometimes metal-core or embedded coin technologies. Check our High Thermal PCB solutions.

Q: Why is ENEPIG preferred over ENIG for optical modules? A: ENEPIG provides a palladium layer that prevents nickel corrosion ("black pad") and offers a superior surface for both gold wire bonding (chip-on-board) and standard soldering.

Resources for Optical Module PCB (related pages and tools)

For those seeking deeper technical data, the following resources provide complementary information to help you design better optical interconnects.

- HDI PCB Manufacturing: Understand the microvia technologies essential for miniaturizing optical modules.

- High Speed PCB Design: A broader look at signal integrity, materials, and layout rules.

- Rogers PCB Materials: Detailed specs on one of the most common material families used in high-performance transceivers.

- Impedance Calculator: A tool to help you estimate trace width and spacing for your required impedance.

Optical Module PCB glossary (key terms)

Finally, to ensure clear communication across teams, we define the essential terminology used throughout this guide.

| Term | Definition |

|---|---|

| PAM4 | Pulse Amplitude Modulation 4-level. A modulation scheme used in 400G/800G modules that transmits two bits per symbol. |

| NRZ | Non-Return to Zero. A binary modulation scheme (0 or 1) used in older or lower-speed modules (10G/25G). |

| SerDes | Serializer/Deserializer. A functional block that converts parallel data to serial data for high-speed transmission. |

| TOSA / ROSA | Transmitter/Receiver Optical Sub-Assembly. The physical components that convert electrons to photons (and back). |

| Backdrilling | A manufacturing process to drill out the unused portion of a plated through-hole (stub) to reduce signal reflection. |

| ENEPIG | Electroless Nickel Electroless Palladium Immersion Gold. A universal surface finish good for soldering and wire bonding. |

| Skew | The time difference between the arrival of signals on two different lines (e.g., P and N of a differential pair). |

| Loss Tangent (Df) | A measure of signal power lost as heat within the PCB dielectric material. |

| CTE | Coefficient of Thermal Expansion. How much the material expands when heated. Mismatch causes reliability issues. |

| Gold Finger | The gold-plated edge connector pads that plug into the host system's socket. |

| HDI | High Density Interconnect. PCB technology using microvias, blind vias, and buried vias to increase circuit density. |

| QSFP-DD | Quad Small Form-factor Pluggable Double Density. A high-speed module form factor supporting 200G and 400G. |

Conclusion (next steps)

Summarizing the journey from definition to validation, successful production of an Optical Module PCB relies on precision at every stage. Whether you are designing for a cost-effective 10G link or a cutting-edge 800G interconnect, the balance between material selection, stackup design, and manufacturing tolerance is vital. These components are the heartbeat of modern data centers, plugging directly into the 1U Server PCB and 2U Server PCB infrastructure that powers the internet.

Ready to move to production? To get an accurate DFM review and quote from APTPCB, please prepare the following:

- Gerber Files: RS-274X format preferred.

- Stackup Diagram: Specify layer count, copper weight, and dielectric thickness.

- Material Spec: Clearly state the laminate (e.g., Megtron 7, Rogers 4350B).

- Impedance Requirements: List target impedance and reference layers.

- Drill Chart: Identify backdrilling locations and via types (blind/buried).

- Surface Finish: Specify ENEPIG, Hard Gold, or other requirements.

Contact our engineering team today to ensure your optical module designs are built for speed and reliability.