Bringing a PCB from concept to stable production requires more than a clean schematic or a well-routed layout. For electronics companies moving toward prototypes, NPI, or mass production, the real challenge is ensuring that the design is manufacturable, consistent, cost-efficient, and assembly-ready.

This is where PCB Design for Manufacturing (DFM) becomes essential. DFM ensures that your PCB can move smoothly through fabrication, assembly, and testing — without unexpected redesigns, yield problems, or costly delays.

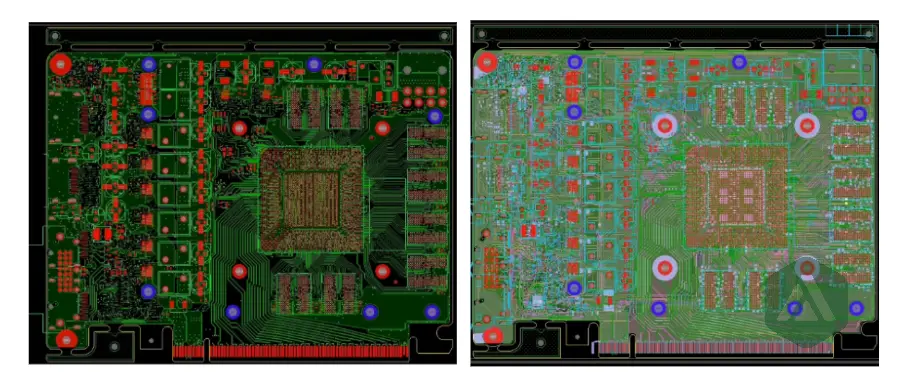

As a factory specializing in PCB manufacturing and full turnkey PCBA, APTPCB reviews every design from a real production perspective. We align your design with actual material behavior, drill tolerances, stack-up constraints, soldering processes, and test requirements, helping you avoid issues long before they reach the production floor.

Our goal is simple:

To help you build PCBs that are manufacturable, reliable, high-yield, and truly ready for volume production.

This guide walks through the fundamentals of PCB Design for Manufacturing, the common pitfalls it prevents, and how partnering early with an experienced factory like APTPCB can ensure a smooth transition from engineering to production — with far fewer risks and far more confidence.

1. What Is PCB Design for Manufacturing (DFM)?

PCB Design for Manufacturing (DFM) is the practice of designing your PCB so that it can be:

- fabricated,

- assembled,

- tested, and

- scaled to volume

efficiently and reliably in a real factory environment.

Good DFM makes sure your PCB design matches:

- Manufacturing capabilities: minimum trace/space, drill sizes, aspect ratios

- Material behavior: dielectric constant, Tg, resin content, copper weight

- Stack-up and impedance rules: what is actually achievable on the line

- SMT assembly constraints: stencil, placement, reflow, and warpage limits

- Test and inspection requirements: ICT, FCT, AOI, X-ray, boundary scan

For many designs, especially mainstream FR4 PCBs and more complex multilayer boards, this alignment between design and process is what keeps projects on schedule and within budget.

In other words, DFM closes the gap between engineering intent and industrial reality.

Without solid PCB DFM:

- a perfectly simulated schematic can become a yield bottleneck, and

- a working prototype can turn into a high-cost, low-yield product at volume.

2. Common PCB This is where PCB Design for Manufacturing (DFM) Problems That Break Production

Most redesigns, delays, and yield problems come from a small set of recurring DFM issues. Typical examples include:

- ❌ Via-in-pad without proper filling → solder wicking, voids, tombstoning

- ❌ Drill size too small for reliable hole plating and mechanical strength

- ❌ Copper too thick for the requested fine-pitch trace/space

- ❌ Spacing too tight for stable etching across the full panel

- ❌ Stack-up incompatible with impedance targets or not available in reality

- ❌ Components too close to board edges, cut-outs, or vias

- ❌ Insufficient solder mask dam → solder bridging under reflow

- ❌ Inconsistent pad sizes / wrong land patterns copied from datasheets

- ❌ High thermal imbalance → warped boards and assembly difficulty

- ❌ No test points or inaccessible nets → expensive ICT/FCT fixtures and debug

The good news: most of these can be avoided simply by involving a manufacturing-experienced factory early in the design phase and aligning your layout with a realistic PCB stack-up from the beginning.

3. Core Principles of Effective PCB Design for Manufacturing

A serious PCB DFM review examines your design from multiple angles. Below are the key pillars APTPCB focuses on when we evaluate “PCB design for manufacturing” for real projects.

3.1 Material Selection & Stack-Up Feasibility

- Matching dielectric constant (Dk), thickness, and resin content

- Ensuring achievable impedance for high-speed / RF nets

- Selecting copper weight that fits both current and manufacturable line width

- Confirming material availability and long-term continuity for volume

For high-speed, high-frequency designs, choosing the right base from our portfolio of high-speed PCBs and low-loss materials is often the difference between a one-time lab success and a stable, repeatable product.

Poorly defined stack-ups are one of the top causes of:

- failed impedance measurements,

- unplanned layer increases, and

- unexpected cost jumps.

3.2 Drill Planning & Via Structures

- Verifying minimum drill size and aspect ratio against factory limits

- Choosing the right mix of through-hole, blind, buried, and microvias

- Ensuring sufficient annular ring under realistic registration tolerance

- Identifying when backdrilling or filled via-in-pad is needed

Every hole in your PCB must be physically manufacturable with margin, not just “allowed” in the CAD tool.

3.3 Trace Width, Spacing & Etch Compensation

- Aligning trace/space with copper thickness and process capability

- Accounting for etch compensation and line width variation

- Considering panel-level uniformity, not just a single coupon

For example, a request like “3.5 mil trace/space on 2 oz copper” needs to be checked against real production capability, especially for mass production. DFM is where the factory either confirms feasibility or suggests safe limits.

When impedance is critical, using tools such as our online impedance calculator together with an agreed stack-up can greatly reduce trial-and-error in layout.

3.4 Solder Mask, Pad Design & Surface Finish

- Setting solder mask openings and dams to avoid bridging

- Aligning pad geometry with stencil design and paste release

- Choosing the right surface finish (ENIG, OSP, LF-HASL, ENEPIG, etc.) for:

- BGA / fine-pitch,

- wire bonding / ENEPIG needs, and

- reliability / corrosion performance

The result is cleaner reflow, fewer defects, and longer-term stability in the field.

3.5 Thermal Management & Warpage Control

- Balancing copper distribution across layers

- Avoiding hot spots through component clustering and layout tweaks

- Selecting board thickness that works with your mechanical and thermal needs

- Considering the number of reflow cycles and assembly steps

For power-dense or high-thermal designs, options such as high-thermal PCBs or metal-based structures can be evaluated as part of the DFM process.

Good DFM for thermal behavior reduces:

- board bow and twist,

- tombstoning and opens, and

- intermittent mechanical and solder-joint failures.

4. This is where PCB Design for Manufacturing (DFM) for PCB Assembly (DFA): The Other Half of Manufacturability

A PCB that is easy to fabricate but hard to assemble is not truly manufacturable.

That’s why Design for Assembly (DFA) is the essential second half of PCB Design for Manufacturing.

Key DFA checks include:

- ✔ Adequate component-to-component spacing for pick-and-place heads

- ✔ Clear and well-placed fiducials for global and local alignment

- ✔ Appropriate stencil thickness and aperture design for paste volume

- ✔ Avoiding shadowing and solder voids near tall components

- ✔ Correct polarity, pin-1 markings, and reference designators

- ✔ Robust BGA design:

- via-in-pad strategy,

- escape routing,

- solder mask definition, and

- X-ray inspectability

Bringing DFA into your PCB design for manufacturing workflow ensures the board is not just “buildable on paper” but smooth to assemble on SMT lines. Our BGA, QFN & fine-pitch assembly capabilities are designed around exactly these kinds of constraints.

5. Why Working with a PCB + PCBA Factory Matters

Many teams rely on:

- built-in EDA DRC/DFM rule sets, or

- design-only firms that don’t operate factories

These are useful, but they have limits:

- ❌ They don’t fully reflect real fab constraints and process drift

- ❌ They lack detail on assembly equipment limits and line behavior

- ❌ They cannot validate stack-up proposals against inventory and supply chain

- ❌ They struggle to predict yield and failure modes at scale

By contrast, a PCB + PCBA factory like APTPCB brings live production data into your design decisions:

- ⭐ Real lamination curves and process windows

- ⭐ Observed copper distribution effects across thousands of panels

- ⭐ Actual drill, etch, and solder mask tolerances held in production

- ⭐ SMT yield experience with similar packages and materials

- ⭐ Integrated view of fabrication + assembly + test

This is why more electronics companies now prefer to work directly with a manufacturing partner who can stand behind DFM, fabrication, and assembly under one roof — from rigid and HDI PCBs to full PCBA.

6. How APTPCB Runs Factory-Level PCB This is where PCB Design for Manufacturing (DFM) Review

When you send your design for a PCB Design for Manufacturing review, APTPCB’s engineering team evaluates:

- Complete Gerber files (or ODB++/IPC-2581 data)

- Centroid and BOM for assembly feasibility

- Proposed stack-up and performance targets

- Impedance-critical nets and routing rules

- Full drill tables and via concepts

- Overall DFx:

- DFM (fabrication)

- DFA (assembly)

- DFT (test strategy, test pads, accessibility)

Based on this, we provide:

- ✔ Practical, factory-backed recommendations instead of generic comments

- ✔ Clear line/space and via limits aligned to your stack-up and copper weight

- ✔ Verified stack-up options that are available and cost-optimized

- ✔ Suggestions to improve yield, warpage, and assembly robustness

- ✔ Risk reports highlighting critical areas (BGAs, HDI, high-speed, power)

- ✔ DFT suggestions: test pads, net access, fixture-friendly layout

All of this is supported by our dedicated testing & quality systems, from SPI and AOI to ICT, FCT, and final inspection.

The goal is simple:

Protect your design, reduce your total cost, and ensure stable mass production.

7. When to Apply PCB Design for Manufacturing in Your Project

The best time to think about PCB Design for Manufacturing is long before first production, not after the first batch fails ICT.

We strongly recommend engaging DFM at these stages:

- ✔ Before prototype layout is frozen

- ✔ Before sending files for quotation (to avoid pricing surprises)

- ✔ Before locking stack-up and materials with other stakeholders

- ✔ Before complex routing of HDI, high-speed, RF, and dense BGAs

- ✔ Before PCBA assembly and stencil fabrication

For fast engineering cycles, using capabilities such as NPI & small batch PCB manufacturing makes it easier to validate DFM decisions before moving to mass production PCB manufacturing.

The earlier DFM starts, the fewer:

- ECOs,

- re-spins,

- lab debugs, and

- “urgent” schedule extensions

Conclusion: PCB Design for Manufacturing Is the Foundation of Reliable Electronics

PCB Design for Manufacturing is not a final checkbox — it is the foundation of every reliable electronic product.

With APTPCB as your manufacturing partner, you gain:

- Factory-level DFM reviews tailored to your product

- Validated stack-ups and materials that can be sustained at volume

- High-yield PCB fabrication aligned with real process windows

- Efficient, robust PCB assembly with DFA and DFT in mind

- A smoother path from NPI to stable mass production

If your next project needs to be manufacturable, cost-effective, and truly production-ready, make PCB Design for Manufacturing part of the design from day one — and work with a factory that understands it at every layer. For application-specific needs, you can also explore our PCB industry solutions across server, automotive, industrial, communication, and more.

Get PCB Design for Manufacturing (DFM) Review from APTPCB

To get actionable PCB DFM feedback from a real factory, you can prepare:

- ✅ Gerber/ODB++/IPC-2581 data

- ✅ Proposed stack-up and key performance requirements

- ✅ Drill files and via structure concepts (HDI, blind, buried, via-in-pad)

- ✅ BOM and placement for critical components (BGAs, high-speed, RF, power)

- ✅ Target quantities, lifetime, and reliability expectations

Share your design package with APTPCB, and our engineers will help you:

- identify DFM and DFA risks before they cost time and money,

- optimize your design for yield, reliability, and cost, and

- bring your PCB from prototype to confident, repeatable production.