Quick answer (30 seconds)

Conducting a thorough review before manufacturing prevents costly respins and assembly delays. A robust set of design review questions pcb focuses on validating connectivity, manufacturability, and physical constraints.

- Verify Schematic-to-Layout Integrity: Ensure the netlist matches exactly and all footprints correspond to the correct BOM components.

- Check Manufacturing Constraints (DFM): Confirm trace widths, spacing, and drill sizes meet the capabilities of APTPCB (APTPCB PCB Factory).

- Validate High-Speed Requirements: Review impedance profiles and length matching, specifically for interfaces like 100BASE-T1 differential pair design.

- Assess Power Integrity: Ensure power planes have sufficient copper weight and decoupling capacitors are placed close to power pins.

- Confirm Mechanical Fit: Check component height against enclosure limits and verify mounting hole locations.

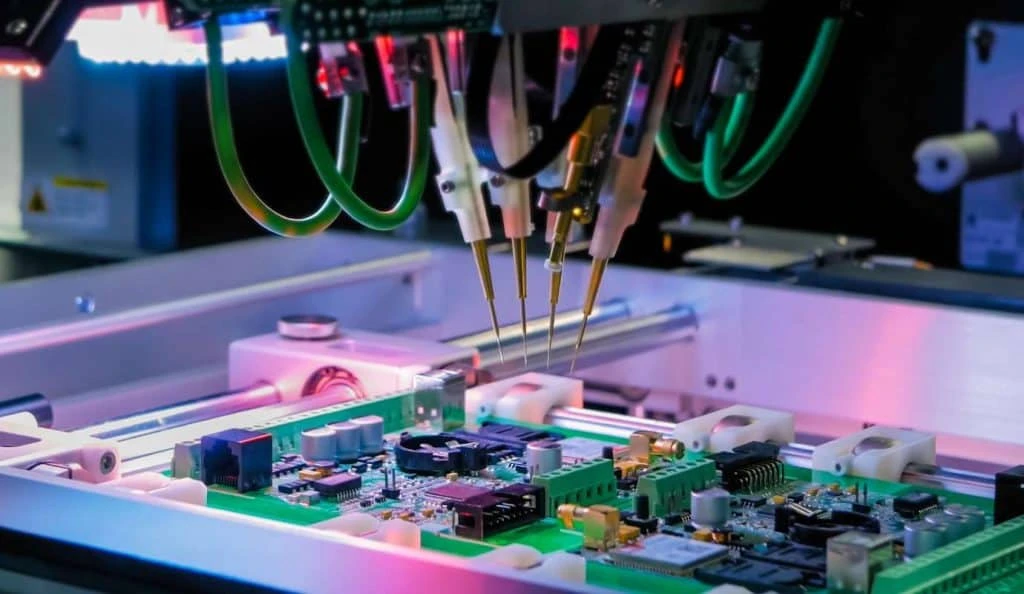

- Review Assembly (DFA): Ensure sufficient spacing between components for pick-and-place machines and soldering tools.

When to use this checklist (and when you can simplify)

Understanding when to apply a formal checklist ensures engineering resources are used effectively.

When to strictly apply design review questions pcb:

- New Product Introduction (NPI): First-time builds require a comprehensive review of every layer and net.

- High-Speed or RF Designs: Complex boards involving 1000BASE-T1 magnetics and layout need rigorous signal integrity checks.

- High-Volume Production: Minor errors in mass production lead to massive scrap costs; a detailed review is mandatory.

- Complex Stackups: Designs utilizing HDI, blind/buried vias, or rigid-flex materials require specific manufacturing validation.

- Safety-Critical Applications: Automotive, medical, and aerospace boards must pass strict reliability reviews.

When a full formal review might be simplified:

- Minor Revision Changes: If only a silkscreen label or a non-critical resistor value changed, a full layout review may be overkill (focus on the delta).

- Simple Breakout Boards: 2-layer adapter boards with low-speed signals often require only basic connectivity and DRC checks.

- Breadboard Prototypes: Early-stage proof-of-concept designs might prioritize speed over perfect DFM, provided they are hand-assembled.

Key design review rules (parameters and limits)

A structured review compares the design against specific physical and electrical rules. The following table outlines critical parameters to verify during the review process.

| Rule Category | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Trace Width | > 4-6 mil (standard) | Ensures current capacity and manufacturability. | DRC & Impedance Calculator. | Overheating or open circuits during etching. |

| Trace Spacing | > 4-6 mil (standard) | Prevents shorts and crosstalk. | DRC (Design Rule Check). | Short circuits or signal interference. |

| Via Size | 0.2mm - 0.3mm (mech drill) | Affects aspect ratio and plating reliability. | Drill table review. | Drill breakage or plating voids. |

| Annular Ring | > 4-5 mil | Ensures via pad is not broken during drilling. | DFM Check. | Open connections (breakout). |

| Impedance Control | ±10% of target (e.g., 50Ω) | Critical for signal integrity on high-speed lines. | Stackup solver / Field solver. | Signal reflection and data corruption. |

| Copper to Edge | > 10-20 mil | Prevents copper exposure during routing/scoring. | DRC / Edge clearance check. | Shorts to chassis or exposed copper. |

| Solder Mask Dam | > 3-4 mil | Prevents solder bridging between pads. | DFM Analysis. | Solder bridges on fine-pitch ICs. |

| Silkscreen Size | > 25-30 mil height | Ensures readability for assemblers. | Visual inspection. | Unreadable text, assembly errors. |

| Thermal Relief | 4 spokes / 10-15 mil | Aids soldering on large copper planes. | Plane settings review. | Cold solder joints (tombstoning). |

| Drill Aspect Ratio | < 8:1 or 10:1 | Ensures plating solution flows through the hole. | Board thickness vs. drill size. | Incomplete barrel plating (open vias). |

| Component Spacing | > 10-20 mil (min) | Allows nozzle access for pick-and-place. | DFA (Design for Assembly) check. | Components cannot be placed or reworked. |

| Test Points | > 30-40 mil pad | Required for ICT or flying probe testing. | Testability review. | Inability to test board automatically. |

Review process (implementation checkpoints)

Following a sequential process ensures no aspect of the design is overlooked.

Schematic and Netlist Verification

- Action: Compare the layout netlist against the schematic.

- Key Parameter: 0 errors in netlist comparison.

- Acceptance Check: Confirm all pins are connected as intended and no "unrouted nets" remain.

Mechanical Constraints and Footprint Review

- Action: Overlay the PCB 3D model with the enclosure STEP file.

- Key Parameter: Clearance > 0.5mm (or per spec) from casing.

- Acceptance Check: Verify connectors align with cutouts and tall capacitors do not hit the lid.

Component Placement and Thermal Review

- Action: Check placement of heat-generating components relative to sensitive ICs.

- Key Parameter: Junction temperature (Tj) < Max rating.

- Acceptance Check: Ensure airflow paths are clear and thermal vias are present under power pads.

Critical Signal Routing (High-Speed/RF)

- Action: Review routing for impedance-controlled lines.

- Key Parameter: 100BASE-T1 differential pair design length matching < 5 mil (or per spec).

- Acceptance Check: Verify continuous reference planes (no splits) under high-speed traces.

Power Distribution Network (PDN) Check

- Action: Analyze voltage drop and current density on power rails.

- Key Parameter: Voltage drop < 3-5%.

- Acceptance Check: Confirm trace widths are sufficient for the current and decoupling caps are close to pins.

DFM and DFA Final Sweep

- Action: Run a manufacturer-specific DFM check (using APTPCB constraints).

- Key Parameter: Min trace/space and drill sizes meet "Standard" or "Advanced" capabilities.

- Acceptance Check: No DRC violations; acid traps and slivers removed.

Silkscreen and Documentation Review

- Action: Check polarity markers and reference designators.

- Key Parameter: Text is not over pads or vias.

- Acceptance Check: Pin 1 is clearly marked for all ICs and connectors.

Gerber and Output Generation

- Action: Generate Gerber X2 or ODB++ files and view them in a third-party viewer.

- Key Parameter: File alignment and format.

- Acceptance Check: Layers align perfectly; drill file matches drill chart.

design review questions pcb troubleshooting (failure modes and fixes)

Even with a checklist, issues can slip through. Here is how to troubleshoot common failures identified during or after the review.

Symptom: High-speed data errors (Packet Loss)

- Causes: Impedance mismatch, stubs, or reference plane splits.

- Checks: Did you verify the 1000BASE-T1 magnetics and layout return path? Are there vias breaking the ground plane?

- Fix: Respin to stitch ground planes or remove stubs.

- Prevention: Use simulation tools during the routing phase.

Symptom: Solder bridging on fine-pitch ICs

- Causes: Insufficient solder mask dam or stencil aperture too large.

- Checks: Is the solder mask web < 3 mil? Is the stencil reduction applied?

- Fix: Modify stencil design (reduce aperture); for PCB, increase spacing if possible.

- Prevention: Adhere to strict DFM rules for fine-pitch components.

Symptom: Board does not fit in enclosure

- Causes: Connector placement offset or component height violation.

- Checks: Was a 3D interference check performed? Were "keep-out" zones respected?

- Fix: Mechanical modification of the enclosure (if cheaper) or PCB layout adjustment.

- Prevention: Import mechanical STEP files into the ECAD tool before routing.

Symptom: Noisy Analog Signals

- Causes: Digital return currents crossing analog areas (Shared Ground impedance).

- Checks: Are analog and digital grounds separated or properly partitioned?

- Fix: Cut traces and jump wire for prototype; redesign ground plane for production.

- Prevention: Proper floorplanning and return path analysis.

Symptom: Open Vias (Intermittent connection)

- Causes: Aspect ratio too high prevents plating; trapped air.

- Checks: Is board thickness to drill diameter ratio > 10:1?

- Fix: Use larger vias or thinner board material.

- Prevention: Check drill table against manufacturer capabilities.

Symptom: Tombstoning of passive components

- Causes: Uneven thermal mass on pads (one pad on large plane, one on thin trace).

- Checks: Are thermal reliefs used on plane connections?

- Fix: Hand rework; modify layout to add thermal spokes.

- Prevention: Enforce thermal relief rules in CAD software.

How to prioritize design review questions pcb (design decisions and trade-offs)

Not all design review questions carry equal weight. Prioritizing them depends on the board's complexity and application.

1. Functionality vs. Manufacturability For a prototype, functionality (connectivity) is paramount. You might accept a lower yield or higher cost to get it done fast. For mass production, DFM questions (yield, cost, testability) become the top priority.

2. Signal Integrity vs. Layout Density In high-speed designs involving 100BASE-T1 differential pair design, signal integrity dictates the layout. You must prioritize questions about impedance and return paths over questions about minimizing board size or layer count. If the signal fails, the board is useless.

3. Cost vs. Performance Questions regarding stackup materials (e.g., FR4 vs. Rogers) directly impact cost. If your design review questions pcb reveal marginal signal performance on FR4, you must decide if the cost of specialized material is justified.

4. Manual Inspection vs. Automated Checks Trust DRC for spacing and width, but prioritize manual review for "intent" questions. A DRC passes a trace routed over a split plane, but a manual review catches the EMI risk. Focus human effort on logic and physics, not just geometry.

design review questions pcb FAQ (cost, lead time, common defects, acceptance criteria, Check Manufacturing Constraints (DFM) files)

Q: How does a thorough design review affect PCB cost? A: It reduces cost significantly by preventing respins. While it adds engineering time upfront, catching a DFM violation (like a drill size that requires a custom tool) prevents manufacturer upcharges.

- Prevents scrap.

- Avoids "advanced technology" surcharges by optimizing for standard specs.

Q: What are the critical design review questions for high-speed interfaces? A: You must ask: Is the continuous reference plane maintained? Are differential pairs length-matched within tolerance?

- Specifically check 1000BASE-T1 magnetics and layout for isolation and symmetry.

- Verify via stubs are back-drilled or minimized.

Q: Does APTPCB offer a DFM review service? A: Yes, APTPCB performs a DFM check on all orders. However, engineers should perform their own review before submission to minimize hold times.

Q: What files are needed for a proper design review? A:

- Gerber files (all layers).

- Drill files (NC Drill).

- IPC-356 Netlist (for electrical test comparison).

- Assembly drawings and Pick & Place files (for DFA).

Q: How do I validate 100BASE-T1 differential pair design during review? A: Check that the differential impedance is 100Ω ±10%. Ensure the pair is routed together without splitting around obstacles, and verify that the mode conversion limits are met by maintaining symmetry.

Q: What is the impact of skipping the "Mechanical Fit" question? A: The board may be electrically perfect but physically useless.

- Connectors may be recessed too far.

- Mounting holes may not align with standoffs.

- Tall components may prevent the case from closing.

Q: What are the acceptance criteria for a PCB design review? A:

- 0 DRC errors.

- 0 Unrouted nets.

- All DFM queries resolved.

- Simulation results (if applicable) meet spec margins.

Q: How long does a typical design review take? A: It varies from 2 hours for a simple microcontroller board to several days for a complex server motherboard. Allocating 10-20% of the total design time to review is a good rule of thumb.

Q: Can software automate all design review questions pcb? A: No. Software checks rules (DRC), but it cannot check intent. It won't know if you accidentally swapped the TX and RX lines on a UART unless you verify the schematic logic manually.

Q: What questions should I ask regarding PCB testing? A: Ask: Are there enough test points for ICT? Is there a dedicated ground point for the probe?

- See First Article Inspection for more on how we validate the first unit.

design review questions pcb glossary (key terms)

| Term | Definition |

|---|---|

| DRC | Design Rule Check; software verification of spacing and width rules. |

| DFM | Design for Manufacturability; optimizing the design for the factory's process window. |

| Netlist | A list of all electrical connections (nets) and components in the design. |

| Gerber | The standard file format used to convey PCB layer data to manufacturing. |

| Impedance | The opposition to AC current flow; critical for high-speed signal integrity. |

| Differential Pair | Two complementary signals used to transmit data with high noise immunity. |

| Return Path | The path current takes to return to the source; usually on the ground plane. |

| Fiducial | Optical markers used by pick-and-place machines to align the board. |

| Stackup | The arrangement of copper and insulating layers in the PCB. |

| Tombstoning | A defect where a component stands up on one end during reflow soldering. |

| IPC Class | Industry standard level (Class 2 for standard, Class 3 for high reliability). |

| BOM | Bill of Materials; the list of all components to be assembled. |

Related resources

- DFM Guidelines: baseline constraints to check before you send files.

- PCB stack-up: lock structure early to avoid SI/PI surprises.

- PCB manufacturing: what process limits matter in production.

- Full turnkey PCBA: assembly constraints that should influence placement.

Request a quote for design review questions pcb (Check Manufacturing Constraints (DFM) review + pricing)

Ready to move from design to production? APTPCB provides a comprehensive DFM review alongside your quote to ensure your answers to the design review questions pcb translate into a buildable board.

What to send for a precise quote and DFM check:

- Gerber Files: RS-274X or X2 format.

- Fabrication Drawing: Including stackup, material specs, and drill chart.

- Quantity & Lead Time: Prototype or mass production needs.

- Assembly Files: BOM and Pick & Place data if PCBA is required.

Get a Quote and DFM Review Now – We verify your files to prevent manufacturing issues before they happen.

Conclusion (next steps)

Successfully navigating design review questions pcb is the final gate between a digital concept and a physical reality. By systematically validating electrical connectivity, manufacturing constraints, and signal integrity rules—such as those for 1000BASE-T1 magnetics and layout—you ensure a reliable product. APTPCB supports this process with advanced manufacturing capabilities and rigorous quality checks, helping you deliver high-performance electronics right the first time.