Contents

- Highlights

- PCB Prototype vs Mass Production: Definition and Scope

- PCB Prototype vs Mass Production Rules and Specifications

- PCB Prototype vs Mass Production Implementation Steps

- PCB Prototype vs Mass Production Troubleshooting

- 6 Essential Rules for PCB Prototype vs Mass Production (Cheat Sheet)

- FAQ

- Request a Quote / DFM Review for PCB Prototype vs Mass Production

- Conclusion

In the lifecycle of electronics hardware, the transition from pcb prototype vs mass production is the most critical milestone for commercial success. While prototyping focuses on design verification, speed, and functional testing (often ignoring unit cost), mass production prioritizes yield, reliability, and cost-efficiency. A design that works perfectly as a single unit on a lab bench can fail catastrophically when manufactured in batches of 10,000 due to minor process variations or inefficient assembly data.

Understanding the engineering and logistical gap between these two stages is essential. It is not simply a matter of ordering "more." It requires a fundamental shift in how data is prepared, how components are sourced, and how quality is verified.

Quick Answer

For engineers and procurement managers navigating pcb prototype vs mass production, here are the core distinctions and action items:

- Volume & Cost Structure: Prototypes carry high unit costs but low setup fees (or bundled pricing). Mass production requires upfront NRE (Non-Recurring Engineering) tooling charges (e-test fixtures, stencils) but offers significantly lower unit prices as volume increases.

- DFM Rigor: Prototypes often rely on "best effort" manufacturing. Mass production requires strict DFM Guidelines to ensure the board can be assembled automatically without manual intervention.

- Panelization: Prototypes are often made as single units. Mass production demands optimized panelization (arrays) with breakaway rails and fiducials to maximize throughput on SMT lines.

- Testing Strategy: Prototypes use Flying Probe testing (slow, no fixture). Mass production utilizes ICT (In-Circuit Testing) bed-of-nails fixtures for instant electrical verification.

- Material Locking: In mass production, you must validate and lock in specific laminate brands (e.g., Isola, Shengyi) and component MPNs to prevent supply chain disruptions.

- Verification: Always perform a First Article Inspection (FAI) before authorizing the full production run.

Highlights

- Yield is King: In mass production, a 1% defect rate is unacceptable. Design choices must center on maximizing manufacturing yield.

- Standardization: Limiting the variety of drill sizes and component types reduces machine changeover time and cost.

- Supply Chain Validation: Mass production requires checking the "End of Life" (EOL) status of every component in the BOM.

- Process Capability: Understanding the Cpk (Process Capability Index) of your manufacturer ensures your tolerances match their mass production capabilities.

PCB Prototype vs Mass Production: Definition and Scope

The distinction between pcb prototype vs mass production goes beyond quantity; it is a difference in manufacturing philosophy.

PCB Prototyping is an agile process. The goal is to get a physical board in hand as quickly as possible to verify the schematic and layout. Engineers often use Quick Turn PCB services where lead times are measured in hours or days. In this phase, higher costs per board are accepted to save time. Manufacturers might use shared panels (combining multiple customers' designs on one sheet) to reduce tooling costs, and assembly might be partially manual.

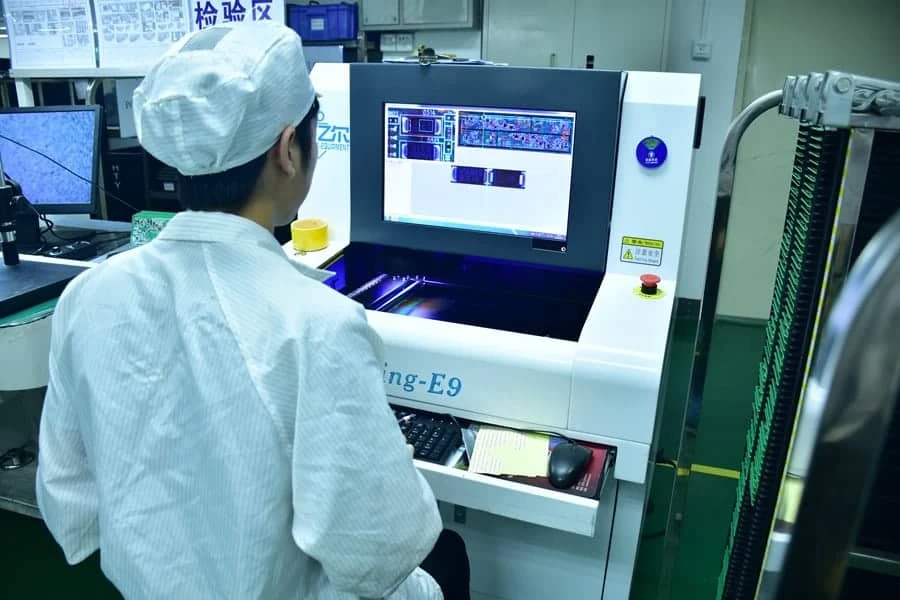

Mass Production, conversely, is a stable, controlled process. It involves dedicated tooling, optimized assembly programs, and rigorous quality control gates. The focus shifts to Process Control. For example, in mass production, the thermal profile of the reflow oven is tuned specifically for the thermal mass of your specific panel to ensure perfect solder joints across thousands of boards. This is where Mass Production PCB Manufacturing expertise becomes vital—balancing throughput with strict quality adherence.

Tech / Decision Lever → Practical Impact

| Decision Lever / Spec | Practical Impact (Yield/Cost/Reliability) |

|---|---|

| Test Method (Flying Probe vs. ICT) | Flying probe is free but slow (Prototype). ICT requires expensive fixtures ($1k+) but tests boards in seconds (Mass Production). |

| Solder Mask Dams | Prototypes may tolerate missing dams. Mass production requires strict dams to prevent solder bridging during wave/reflow soldering. |

| Panelization Strategy | Single units are fine for lab testing. Mass production requires arrays with tooling rails to fit SMT conveyors and maximize material usage. |

| Component Sourcing | Prototypes use catalog distributors (DigiKey/Mouser). Mass production requires direct manufacturer reels to lower cost and ensure traceability. |

PCB Prototype vs Mass Production Rules and Specifications

When moving from a prototype design to a mass production candidate, specifications must be tightened. "It worked in the lab" is not a specification. You must define the acceptable range of variation.

| Rule / Spec | Recommended Value (Mass Prod) | Why it matters | How to verify |

|---|---|---|---|

| Trace/Space Tolerance | ±20% (Standard), ±10% (Impedance) | Tighter tolerances increase cost and scrap rate. Design with standard tolerances if possible. | Impedance coupons & microsection analysis. |

| Annular Ring | +0.15mm over drill size | Ensures the drill hole remains within the copper pad despite machine movement (drill wander). | CAM review of Gerber files before fabrication. |

| Solder Mask Expansion | 0.05mm - 0.075mm | Prevents mask from encroaching on pads (soldering issues) or exposing adjacent copper (bridging). | Check "Mask to Pad" clearance in CAD tools. |

| Bow and Twist | < 0.75% (SMT Standard) | Warped boards cause pick-and-place failures and open joints on BGA components. | Place board on flat surface; measure max lift height. |

| Copper Balance | Symmetric Stackup | Asymmetric copper distribution causes warping during thermal cycles (reflow). | Review layer stackup for copper weight symmetry. |

For complex designs involving high-density interconnects, consulting our HDI PCB capabilities early in the design phase can prevent costly redesigns when scaling up.

PCB Prototype vs Mass Production Implementation Steps

Transitioning to mass production is often referred to as NPI (New Product Introduction). This is a structured process to reduce risk.

Implementation Process

Step-by-step execution guide

Stop all feature changes. Submit data for a comprehensive DFM review to identify features that yield poorly at volume (e.g., acid traps, slivers).

Resolve all technical queries (EQs) from the CAM engineers. Define panelization, impedance requirements, and specific material brands (e.g., Rogers vs. FR4).

Run a small volume (50-100 units) using production tooling. This validates the SMT program, stencil design, and reflow profile before full commitment.

The first board off the production line is fully inspected (X-Ray, AOI, functional test). Only after FAI approval does the rest of the batch proceed.

PCB Prototype vs Mass Production Troubleshooting

Even with careful planning, issues can arise when scaling up. Here are common failure modes in the pcb prototype vs mass production transition and how to fix them.

1. Tombstoning of Passive Components

Issue: Small resistors or capacitors stand up vertically on one pad during reflow. Cause: Uneven heating or asymmetric pad design. In prototypes, hand soldering hides this. In mass production, the reflow oven exposes thermal imbalances. Fix: Ensure thermal relief connections are used for pads connected to large copper planes. Verify that pad sizes are identical for both sides of the component.

2. Solder Bridging on Fine Pitch Ics

Issue: Shorts between pins on QFP or connector components. Cause: Stencil aperture is too large, or solder mask dams are missing between pins. Fix: Reduce stencil aperture by 10-15% for fine-pitch pads. Ensure the PCB design includes solder mask dams (min 3-4 mil) between every pin.

3. Warpage During Reflow

Issue: The board bows or twists, causing BGA open circuits. Cause: Unbalanced copper stackup or using thin cores (e.g., 0.8mm) without pallets. Fix: Use a balanced stackup (mirror layers from the center). For thin boards, use SMT carrier pallets during assembly.

6 Essential Rules for PCB Prototype vs Mass Production (Cheat Sheet)

| Rule / Guideline | Why It Matters (Physics/Cost) | Target Value / Action |

|---|---|---|

| Panelization with Rails | Machines need edges to grip. Single boards slow down the line significantly. | 5-7mm rails + Fiducials |

| Component Availability | A single out-of-stock part can halt 10,000 boards. | Check EOL status & Alternates |

| Test Points | ICT fixtures need physical access to nets to verify assembly. | 1mm pad on bottom side |

| Thermal Reliefs | Direct connection to planes sucks heat away, causing cold solder joints. | 4-spoke relief on GND pads |

| Surface Finish | HASL is cheap but uneven. ENIG is flat but costs more. | ENIG for Fine Pitch / BGA |

| Standardization | Unique drill sizes require tool changes. Unique parts require feeder slots. | Consolidate BOM & Drills |

FAQ

Q: At what quantity should I switch from prototype to mass production?

A: Typically, the crossover point is between 50 and 100 units. Below this, the NRE costs (stencils, fixtures) might outweigh the unit savings. Above 100 units, NPI Small Batch or mass production processes become more economical and reliable.

Q: Can I use the exact same Gerber files for mass production as I did for the prototype?

A: Usually, no. While the copper layers remain the same, the manufacturing data often changes. You will need to add panelization (arrays), tooling holes, and fiducials for the assembly machines. It is best to let your manufacturer handle the panelization to match their equipment.

Q: How does the lead time differ?

A: Prototypes can be done in 24-48 hours. Mass production typically requires 10-15 working days for standard PCBs, plus additional time for component procurement and assembly. This allows for batching, queue optimization, and thorough QC.

Q: Why is the unit price so much lower in mass production?

A: Mass production benefits from economies of scale. Setup costs (CAM engineering, machine programming, stencil creation) are amortized over thousands of units. Additionally, materials are purchased in bulk, and machine throughput is optimized to reduce run time per board.

Request a Quote / DFM Review for PCB Prototype vs Mass Production

Ready to scale your design? Whether you need a quick prototype to validate a concept or are ready to run 50,000 units, APTPCB has the infrastructure to support you.

Checklist for Quote:

- Gerber Files: RS-274X format (all layers).

- BOM (Bill of Materials): Include Manufacturer Part Numbers (MPN) and quantities.

- Pick & Place File: Centroid data for assembly.

- Quantity: Estimated annual volume and batch size.

- Special Requirements: Impedance control, specific stackup, or testing requirements.

Conclusion

The journey from pcb prototype vs mass production is about maturing your design from a functional concept into a manufacturable product. By focusing on DFM, standardizing components, and implementing rigorous testing strategies like ICT, you can ensure a smooth transition. Don't let the success of a single prototype lull you into a false sense of security—prepare your data for the rigors of volume manufacturing.

Signed, The Engineering Team at APTPCB