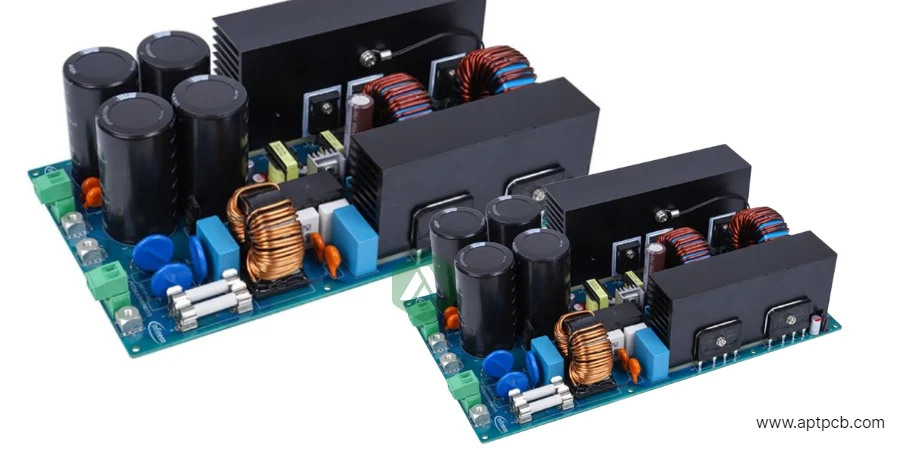

PFC power board assemblies implement active power factor correction achieving >0.99 PF while reducing harmonic distortion to THD <5% meeting EN 61000-3-2, IEEE 519, and global power quality standards across server power supplies (1-3kW), telecommunications infrastructure (1-5kW), industrial equipment (2-10kW+), and grid-scale converters requiring optimized grid interface, minimal harmonic pollution, and high efficiency (>95%) supporting reliable operation through millions of switching cycles.

At APTPCB, we deliver specialized PFC assembly services implementing boost, interleaved, and bridgeless topologies with power energy expertise. Our capabilities support single-phase and three-phase PFC across power ranges from 300W through 100kW+ with comprehensive harmonic testing validating compliance with international power quality standards.

Achieving High Power Factor and Low THD

Active PFC circuits shape input current waveforms to follow input voltage achieving near-unity power factor (typically >0.99) and low total harmonic distortion (typically <5%) significantly exceeding passive PFC performance (<0.7 PF, >30% THD) and meeting stringent regulatory requirements while improving system efficiency and enabling higher power loading on building electrical infrastructure.

At APTPCB, our assembly services implement optimized PFC topologies achieving power quality targets.

Key PFC Performance Requirements

Boost PFC Topology

- Continuous conduction mode (CCM) operation maintaining sinusoidal input current at rated power with automotive electronics grade component reliability

- Average current mode control using dedicated PFC controllers (UCC28070, L6563, NCP1654)

- DC bus regulation maintaining 380-400VDC output voltage across input and load variations

- Inductor design balancing ripple current, efficiency, and physical size

- High-voltage MOSFET and diode selection withstanding 600-800V with adequate margins

- Efficiency optimization achieving >95% at rated load through component selection and layout

Interleaved PFC Implementation

- Multi-phase operation (typically 2-4 phases) reducing input current ripple and EMI

- Phase shedding at light loads improving efficiency across full load range

- Current sharing ensuring balanced loading between parallel phases

- Reduced component stress distributing power across multiple semiconductors

- Compact magnetic design using coupled inductors reducing size and weight

- Advanced control ICs managing interleaving timing and current balancing

Managing High-Frequency Switching and EMI

PFC converters operate at 50-150kHz switching frequencies requiring careful PCB layout minimizing parasitic inductance, comprehensive EMI filtering meeting conducted emissions standards, and thermal management handling kilowatts of throughput power. Inadequate design causes excessive EMI, switching losses, or component overheating compromising performance and reliability.

APTPCB implements high-frequency optimized layouts supporting reliable PFC operation.

Key High-Frequency Design

PCB Layout Optimization

- Minimized switching loop inductance reducing ringing and voltage overshoot

- Wide traces in high-current paths minimizing resistive losses

- Ground plane distribution providing low-impedance return paths

- Component placement keeping gate drive circuits close to switches

- Thermal via arrays transferring heat from power components

- Multi-layer construction with power planes distributing current

EMI Management

- Input filter coordination with PFC stage achieving overall emissions compliance

- Common-mode choke after PFC reducing high-frequency noise

- Snubber circuits controlling ringing and reducing radiated emissions

- Shielding when required isolating PFC section from sensitive circuits

- Pre-compliance testing identifying EMI issues during development

- Validation testing confirming compliance with EN 55022 and FCC Part 15

Implementing Three-Phase PFC Systems

High-power applications (>10kW) often use three-phase PFC providing balanced loading on three-phase supplies, reduced component stress per phase, and improved efficiency. Three-phase implementations require phase sequence detection, balanced current control, and coordination between phases achieving overall power quality targets.

APTPCB assembles three-phase PFC systems supporting industrial and utility applications.

Key Three-Phase Implementation

Topology Options

- Vienna rectifier (three-level boost) reducing switch voltage stress to Vdc/2

- Six-switch boost topology providing flexible control and bidirectional capability

- Swiss rectifier minimizing switch count reducing cost and complexity

- Interleaved multi-phase designs distributing power across multiple stages

- Control complexity requiring DSP or FPGA implementation

- Current sensing for each phase enabling balanced current control

System Coordination

- Phase sequence detection identifying A-B-C rotation for proper control

- Neutral current minimization through balanced operation across phases

- DC bus voltage regulation maintaining constant output despite three-phase variations

- Fault handling coordinating between phases during loss-of-phase or imbalance conditions

- Communication interfaces reporting status and power quality metrics

- Comprehensive protection preventing damage during abnormal grid conditions

Ensuring Harmonic Compliance and Testing

PFC validation requires harmonic analysis confirming compliance with EN 61000-3-2 (equipment <16A), IEEE 519 (utility interconnection), or IEC 61000-3-12 (equipment >16A) measuring individual harmonic amplitudes up to 40th harmonic (2kHz). Comprehensive testing prevents non-compliance requiring design iteration and validates performance across input voltage, output power, and load variations.

APTPCB provides dedicated harmonic testing capabilities.

Key Harmonic Testing

Compliance Measurement

- Harmonic analyzer measuring individual harmonic current amplitudes per standards

- Power factor and displacement power factor measurement quantifying performance

- THD calculation summing harmonic content validating <5-10% targets

- Testing across input voltage range (85-265VAC) confirming compliance at extremes

- Load sweep testing from 25-100% validating harmonic performance across range

- Temperature testing ensuring performance maintained across ambient variations

Power Quality Validation

- RMS current and voltage measurement characterizing input power characteristics

- Waveform capture visualizing input current and voltage for analysis

- Transient testing validating response to load steps and input variations

- Efficiency measurement across operating points confirming >95% targets

- Holdup time testing measuring DC bus voltage decay during input interruption

- Long-term stability testing validating sustained operation maintaining specifications

Supporting Server and Industrial Applications

PFC systems serve diverse high-power applications including data center server supplies (redundant 1+1 or 2+2 configurations), telecommunications rectifiers (48V DC infrastructure), industrial motor drives (400-800V DC bus), and grid-tie inverters (solar, energy storage) requiring application-specific optimizations in redundancy, communications, environmental ratings, and features.

APTPCB supports high-power PFC applications with specialized manufacturing.

Key Application Requirements

Data Center Server Power

- High efficiency (>95% at 50% load) reducing cooling costs and PUE

- High power density (>20W/in³) maximizing server density

- Hot-swap capability enabling field replacement without system shutdown

- PMBus communication providing telemetry and control interfaces

- Hold-up time (>10ms) maintaining operation during brief grid disturbances

- Redundant configurations (N+1) ensuring availability despite single failure

Industrial and Telecom

- Wide operating temperature (-40 to +70°C) surviving unconditioned environments

- Ruggedized construction withstanding vibration and shock

- Three-phase input capability for high-power installations (>5kW)

- Battery backup coordination enabling seamless transition during outages

- Communication protocols (Modbus, CANbus) integrating into control systems

- Long service life (15-20 years) matching infrastructure equipment expectations

Through application-optimized designs and flexible manufacturing coordinated with support services, APTPCB enables PFC power board manufacturers serving data center, telecommunications, and industrial markets.

Delivering Volume Manufacturing

PFC power board production requires balancing performance, reliability, and cost meeting market expectations while achieving power quality and efficiency specifications. Manufacturing optimization through automation, process control, and supply chain management enables competitive pricing while maintaining quality standards.

APTPCB delivers cost-effective PFC manufacturing through proven processes.

Production Excellence

Manufacturing Capabilities

- Automated assembly handling high-current components and precision placement

- Inline testing validating functionality before full characterization

- Harmonic compliance testing on production samples ensuring ongoing compliance

- Thermal testing confirming designs maintain temperatures under rated conditions

- Statistical process control monitoring yields and identifying improvement opportunities

- Volume capability supporting thousands of units monthly with consistent quality

Through comprehensive manufacturing capabilities and quality systems coordinated with final quality inspection procedures, APTPCB enables PFC manufacturers deploying products meeting global power quality standards across diverse high-power applications.