potting material selection Selecting the correct encapsulation for Battery Management System (BMS): what this playbook covers (and who it’s for)

Selecting the correct encapsulation for a Battery Management System (BMS) is not merely about waterproofing; it is a structural and thermal decision that dictates the safety of the entire energy storage unit. This playbook is designed for hardware engineers, procurement leads, and quality managers who are transitioning a BMS design from prototype to mass production. It addresses the specific challenges of potting material selection BMS, focusing on the interaction between chemical compounds, PCB substrates, and high-voltage components.

Readers will gain a structured approach to defining material specifications that prevent common failures like thermal runaway propagation, solder joint fatigue due to thermal expansion, and dielectric breakdown. We move beyond basic datasheets to explore how viscosity affects manufacturing cycle time and how hardness impacts repairability. The goal is to equip you with the technical criteria needed to audit suppliers and approve a Bill of Materials (BOM) that balances cost with automotive-grade reliability.

At APTPCB (APTPCB PCB Factory), we frequently observe that the gap between a successful prototype and a failed production run often lies in the potting process window. This guide bridges that gap by providing a risk-based validation plan and a procurement checklist. Whether you are building for EVs, grid storage, or industrial robotics, this document serves as your roadmap for securing a robust supply chain.

When potting material selection Selecting the correct encapsulation for Battery Management System (BMS) is the right approach (and when it isn’t)

Understanding the scope of this guide requires first establishing when full encapsulation is necessary versus when lighter protection methods suffice.

Potting is the correct approach when:

- Thermal Management is Critical: The BMS handles high currents (100A+), and the PCB alone cannot dissipate heat effectively. Potting compounds with high thermal conductivity act as a bridge to the metal enclosure.

- High Voltage Isolation is Required: Your design involves a high voltage BMS stackup design (400V or 800V architectures). Potting eliminates air gaps, preventing arcing and corona discharge that standard air clearance cannot manage.

- Vibration and Shock are Constant: The application is automotive or aerospace. The mass of the potting compound dampens vibration, preventing heavy components (like inductors or connectors) from fatigue-cracking their solder joints.

- Security is a Priority: You need to protect intellectual property (IP). Opaque, hard potting makes reverse engineering the circuit significantly more difficult without destroying the board.

Potting might be overkill (or dangerous) when:

- Weight is a Primary Constraint: Potting adds significant mass. For lightweight drones, conformal coating for BMS (like acrylic or parylene) is often preferred if high voltage isolation isn't the main driver.

- Frequent Maintenance is Expected: If fuses or connectors need replacement in the field, hard potting makes rework impossible. In these cases, selective potting or a silicone gel is required.

- RF Interference is Sensitive: Some potting materials have high dielectric constants that can detune antennas or affect high-frequency signal integrity if not accounted for in the design phase.

Specs & requirements (before quoting)

Once you have determined that potting is essential, you must translate performance needs into quantifiable metrics before engaging a manufacturer like APTPCB.

- Thermal Conductivity (W/m·K):

- Target: Typically 0.5 to 2.0 W/m·K for BMS.

- Why: Standard epoxy is an insulator (~0.2 W/m·K). You likely need filled systems to pull heat away from MOSFETs.

- Viscosity (Mixed):

- Target: < 3000 cPs for complex geometries; up to 10,000 cPs for simple pours.

- Why: Low viscosity ensures the material flows under fine-pitch components (BGAs) and displaces air, preventing voids that lead to hot spots.

- Hardness (Shore Scale):

- Target: Shore A 40-80 (Silicone/PU) for stress relief; Shore D 60-80 (Epoxy) for physical armor.

- Why: Too hard transfers stress to components during thermal cycling; too soft offers no mechanical protection.

- Glass Transition Temperature (Tg):

- Target: Must be outside the operating range (usually < -40°C for flexible materials or > 120°C for rigid ones).

- Why: Operating near Tg causes drastic changes in the Coefficient of Thermal Expansion (CTE), ripping components off the board.

- Dielectric Strength:

- Target: > 15 kV/mm.

- Why: Essential for high voltage BMS stackup design to prevent breakdown between high-potential traces and the chassis.

- Cure Profile (Time vs. Temp):

- Target: Room temp cure (24h) vs. Heat cure (1h @ 80°C).

- Why: Heat curing is faster for volume but risks damaging heat-sensitive battery cells if the BMS is potted while attached to the pack.

- Flame Retardancy:

- Target: UL94 V-0.

- Why: Non-negotiable for battery safety. The material must self-extinguish if a component fails and ignites.

- CTE (Coefficient of Thermal Expansion):

- Target: < 50 ppm/°C (for rigid); higher is acceptable for soft silicones.

- Why: Mismatch between the PCB (FR4 ~14-17 ppm) and potting causes warping and solder fractures.

- Chemical Resistance:

- Target: Resistant to electrolyte leakage (if near cells) and cleaning solvents.

- Why: Battery electrolyte is corrosive and can degrade the potting interface over time.

- Adhesion Strength:

- Target: Specific to the housing material (Aluminum, ABS, PC).

- Why: Delamination creates moisture traps. You may need a primer or plasma treatment specification.

Hidden risks (root causes & prevention)

Defining requirements is the first step; understanding how potting material selection BMS fails in production is the second step to ensuring longevity.

Risk: Exothermic Reaction "Cooking" Components

- Why it happens: Fast-curing epoxies generate significant heat during the chemical reaction. Large volumes (thick pours) trap this heat.

- Detection: Thermocouples placed inside the potting mass during prototyping.

- Prevention: Choose low-exotherm formulations or use a multi-stage pour process to let heat dissipate.

Risk: CTE Mismatch Shearing Solder Joints

- Why it happens: The potting expands faster than the component or PCB during heating. If the material is too hard (high modulus), it shears the component legs.

- Detection: Thermal cycling tests (-40°C to +85°C) followed by cross-sectioning.

- Prevention: Use a flexible material (Polyurethane/Silicone) or a "glob top" buffer around sensitive ICs before full potting.

Risk: Voids Causing High Voltage Arcing

- Why it happens: Air bubbles get trapped under components or in corners during dispensing. Air has a lower dielectric strength than potting.

- Detection: X-ray inspection or partial discharge testing.

- Prevention: Mandate vacuum potting (dispensing and curing in a vacuum chamber) for all HV designs.

Risk: Catalyst Poisoning (Silicone)

- Why it happens: Platinum-cure silicones fail to cure if they touch sulfur, amines, or tin (often found in solder masks or other adhesives).

- Detection: The material remains "gooey" at the interface after the cure cycle.

- Prevention: Verify chemical compatibility of the solder mask and flux residues with the silicone supplier.

Risk: Sedimentation of Fillers

- Why it happens: Thermal fillers (ceramics) are heavy and sink to the bottom of the drum or the dispenser tank.

- Detection: Inconsistent thermal performance or hardness across a batch.

- Prevention: Require suppliers to use agitated tanks and continuous recirculation lines.

Risk: CTI Failure on the PCB

- Why it happens: Even with potting, the interface between the PCB and potting can track.

- Detection: Hipot and leakage test BMS failures in humid conditions.

- Prevention: Specify high CTI laminate for BMS (CTI > 600V, PLC 0) to ensure the board material itself resists tracking.

Risk: Sensor Interference

- Why it happens: Potting exerts pressure on MEMS sensors (gyroscopes, pressure sensors) or alters the thermal mass around temp sensors.

- Detection: Offset readings in functional testing.

- Prevention: Use a protective cap or dam around sensors to keep them free of potting.

Risk: Wire Breakage During Cure

- Why it happens: Potting shrinks as it cures. If wires are tight, the shrinkage snaps them.

- Detection: Open circuit faults post-cure.

- Prevention: Leave "service loops" or slack in wires and cables before potting.

Validation plan (what to test, when, and what “pass” means)

To mitigate the risks identified above, a rigorous validation plan is required before mass production release.

- Thermal Shock Testing:

- Objective: Verify CTE compatibility.

- Method: 100 cycles, -40°C to +125°C (or max rating), < 10 sec transfer.

- Pass Criteria: No visible cracks in potting; no electrical continuity loss; no delamination from housing.

- Powered Thermal Cycling (PTC):

- Objective: Test thermal dissipation.

- Method: Run BMS at max current while cycling ambient temp.

- Pass Criteria: Component junction temperatures remain within safe limits (e.g., MOSFETs < 100°C).

- Hipot and Leakage Test BMS:

- Objective: Verify dielectric isolation.

- Method: Apply high voltage (e.g., 2500V DC) between HV terminals and chassis/LV ground.

- Pass Criteria: Leakage current < 1mA (or specific spec); no breakdown.

- Damp Heat Test:

- Objective: Check hydrolytic stability (especially for Polyurethanes).

- Method: 85°C / 85% RH for 1000 hours.

- Pass Criteria: Potting does not turn to "mush" (reversion); insulation resistance remains high.

- Vibration Testing:

- Objective: Simulate road/flight conditions.

- Method: Random vibration profiles (e.g., ISO 16750-3) for X, Y, Z axes.

- Pass Criteria: No physical damage; no intermittent electrical contact.

- Cross-Sectioning (Destructive):

- Objective: Check for internal voids and fill quality.

- Method: Cut a potted unit through critical areas (under BGAs, transformers).

- Pass Criteria: > 95% fill; no voids bridging HV conductors.

- Adhesion Pull Test:

- Objective: Verify bond to housing.

- Method: Attempt to peel potting from the case wall.

- Pass Criteria: Cohesive failure (potting tears) rather than adhesive failure (peels clean off wall).

- Flammability Test:

- Objective: Verify safety compliance.

- Method: Apply flame per UL94 standards (if not already certified).

- Pass Criteria: Self-extinguishes within specified time; no flaming drips.

- Chemical Compatibility Check:

- Objective: Ensure no reaction with other BMS materials.

- Method: Immersion of wires/connectors in uncured potting; immersion of cured potting in electrolyte.

- Pass Criteria: No swelling, cracking, or discoloration.

- AEC-Q100 Validation for BMS (Context):

- Objective: Ensure the ICs inside the potting survive the stress.

- Method: Review IC datasheets for package stress ratings.

- Pass Criteria: Confirmation that potting stress (shrinkage) does not exceed IC package limits.

Supplier checklist (RFQ + audit questions)

When selecting a manufacturing partner, use this checklist to ensure they can handle the complexities of potting material selection BMS.

RFQ Inputs (What you send):

- 3D CAD model of the PCBA and Enclosure (STEP format).

- "Keep Out" zones clearly marked (connectors, sensors, test points).

- Potting material datasheet (or performance requirements if selecting).

- Volume per unit (cc) and weight tolerance.

- Curing constraints (max temp, max time).

- Cosmetic requirements (surface finish, color, allowable bubbles on top).

- Testing requirements (100% Hipot? 100% Visual?).

- Packaging requirements (trays, ESD protection).

Capability Proof (What they demonstrate):

- Do they have vacuum potting chambers? (Critical for HV).

- Can they handle 2-part mixing with dynamic mixing heads?

- Do they have automated dispensing robots (3-axis or 5-axis)?

- Can they demonstrate experience with high voltage BMS stackup design assembly?

- Do they have X-ray capability for void detection?

- Can they process high-viscosity, thermally conductive materials?

Quality System & Traceability:

- Is the mixing ratio monitored in real-time? (Alarm if ratio drifts).

- Is the pot life (working time) tracked automatically?

- Are material batch numbers linked to specific PCBA serial numbers?

- Is there a procedure for purging mixing nozzles to prevent cross-contamination?

- Do they perform incoming QC on the resin (viscosity check, filler settling)?

- Is there a "shore hardness" check on a sample coupon for every shift/batch?

Change Control & Delivery:

- What is the procedure if the resin manufacturer changes the formulation?

- How are partial drums stored (humidity control, nitrogen blanket)?

- Can they scale from prototype (hand pour) to production (automated) without changing the process validation?

- Do they have temperature-controlled shipping for the finished goods if necessary?

- What is the contingency plan for equipment downtime (redundant lines)?

- How do they handle rework or scrap of potted units?

Decision guidance (trade-offs you can actually choose)

Every potting decision involves a compromise. Here is how to navigate the most common trade-offs in potting material selection BMS.

- Repairability vs. Protection:

- If you prioritize field repair: Choose Silicone Gel or a soft Polyurethane. These can be dug out.

- If you prioritize IP protection and ruggedness: Choose a hard Epoxy. It is permanent and tamper-evident.

- Thermal Performance vs. Flow:

- If you prioritize heat dissipation: Choose a heavily filled ceramic epoxy (> 1.5 W/mK). Be prepared for higher viscosity and slower dispensing.

- If you prioritize gap filling and speed: Choose a low-viscosity unfilled urethane. It flows fast but insulates heat.

- Cost vs. Temperature Range:

- If you prioritize extreme temps (> 150°C): Choose Silicone. It is the most expensive but stable.

- If you prioritize cost: Choose Polyurethane or Epoxy. They are cheaper but brittle at very low temps or degrade at very high temps.

- Stress vs. Adhesion:

- If you prioritize low stress on components: Choose Silicone. It has low modulus.

- If you prioritize adhesion to the case: Choose Epoxy. Silicones often require primers and adhere poorly to some plastics.

- Weight vs. Isolation:

- If you prioritize weight reduction: Consider conformal coating for BMS combined with strategic "dam and fill" only over HV areas.

- If you prioritize max voltage isolation: Full encapsulation is the only safe option for compact HV designs.

FAQ

Q: Can I just use conformal coating instead of potting for a BMS? A: For low-voltage (< 48V) consumer electronics, yes. However, conformal coating for BMS does not provide the thermal mass or the high-voltage arc suppression required for EV or industrial grid storage systems.

Q: How do I prevent air bubbles in my potting? A: The most effective method is vacuum potting, where the material is degassed and dispensed in a vacuum chamber. Alternatively, heating the material (to lower viscosity) and bottom-up filling can help reduce voids.

Q: What is the difference between potting and encapsulation? A: They are often used interchangeably. Technically, "potting" implies the shell (the "pot") stays with the product, while "encapsulation" or "casting" might involve removing the mold. In BMS, the housing usually stays.

Q: How thick should the potting layer be? A: It depends on the voltage. A general rule is to ensure at least 2-3mm of coverage over the tallest high-voltage component, but dielectric strength calculations should dictate the exact minimum.

Q: Will potting affect my RF antenna performance? A: Yes. Potting materials have a dielectric constant (Dk) different from air. This will detune antennas. You should either keep the antenna out of the potting or retune the antenna with the potting material present.

Q: Can APTPCB help with material selection? A: Yes. APTPCB engineers can review your thermal and environmental requirements to suggest suitable material classes and coordinate with resin suppliers.

Q: What happens if the potting is too hard? A: During thermal cycling, the PCB and components expand. If the potting is too hard (high modulus), it won't yield, causing solder joints to crack or ceramic capacitors to fracture.

Q: Is potting reversible? A: Generally, no. While some soft silicones can be removed manually, it is labor-intensive and risks damaging the board. Treat potted assemblies as non-repairable units.

Related pages & tools

- PCB Conformal Coating Services – Understand the alternative to potting for lighter-duty protection and how we apply it.

- Automotive Electronics PCB Manufacturing – Explore our capabilities in building high-reliability boards that meet AEC-Q standards.

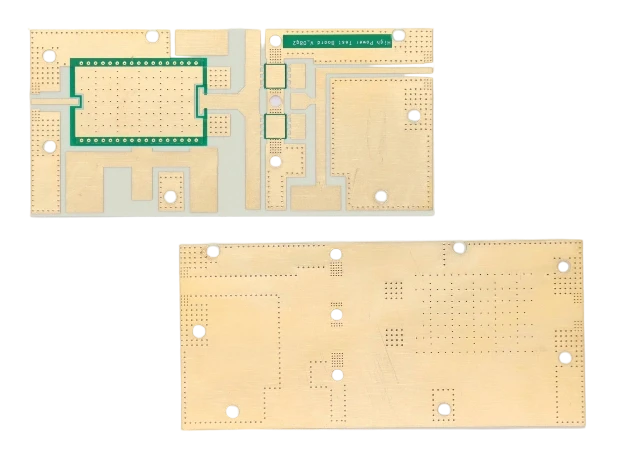

- Power & Energy PCB Solutions – See how we handle heavy copper and high-voltage designs for BMS and inverters.

- High Thermal PCB Materials – Learn about metal-core and high-conductivity substrates that work in tandem with potting.

- PCBA Testing & Quality Control – Details on our testing protocols, including functional and environmental stress testing.

Request a quote

Click here to request a DFM review and Quote – Our engineering team will review your potting material selection BMS requirements and stackup to ensure manufacturability.

For the most accurate quote, please provide:

- Gerber files and BOM.

- Potting material specification (or performance goals).

- 3D STEP file of the assembly (PCBA + Enclosure).

- Estimated annual volume.

- Testing requirements (e.g., Hipot, Leakage).

Conclusion

Successful potting material selection BMS is a balancing act between thermal management, electrical isolation, and mechanical stress relief. It transforms a fragile PCB into a robust automotive-grade component capable of surviving harsh environments. By defining clear requirements for viscosity, hardness, and thermal conductivity, and by validating these choices against risks like CTE mismatch and voids, you ensure the safety and longevity of your battery system. APTPCB is ready to support this transition from design to scaled production with rigorous process control and expert guidance.