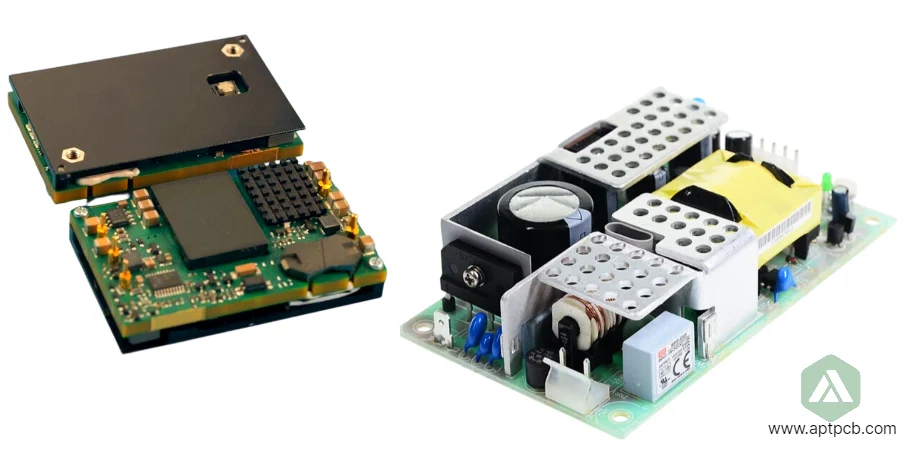

Power control board assemblies integrate microcontrollers, power monitoring circuits, relay drivers, and communication interfaces enabling intelligent load management, energy optimization, and remote control across industrial automation, renewable energy systems, building management, and smart grid infrastructure requiring precise measurement accuracy (±0.5%), reliable switching (millions of cycles), and continuous operation supporting critical power management applications through 15-20 year service lives.

At APTPCB, we deliver specialized power control assembly services implementing advanced monitoring algorithms, multi-channel control, and robust communication protocols with turnkey assembly capabilities. Our expertise supports 100W through 100kW+ control systems across voltage ranges from 12VDC through 480VAC three-phase with comprehensive functional validation and compliance testing.

Achieving Precision Power Measurement and Monitoring

Accurate power measurement forms the foundation of intelligent control systems, yet achieving <0.5% accuracy across wide dynamic ranges while measuring voltage, current, power factor, and harmonics simultaneously presents significant technical challenges. Inadequate measurement precision causes incorrect load calculations, suboptimal control decisions, and billing errors in commercial applications — all directly impacting system effectiveness and customer trust.

At APTPCB, our assembly services implement validated measurement architectures ensuring accuracy across full operating ranges.

Key Measurement Implementation Techniques

- High-Resolution ADC Integration: 16-24 bit delta-sigma ADCs with simultaneous sampling capturing voltage and current waveforms at 4-8kHz rates enabling accurate real-time power calculations across varying load conditions.

- Precision Current Sensing: Calibrated shunt resistors (±0.1%) or Hall effect sensors with temperature compensation maintaining accuracy across -40 to +85°C operating ranges ensuring consistent measurement despite environmental variations.

- Voltage Isolation and Conditioning: Transformer or resistive divider networks with precision amplifiers providing galvanic isolation while maintaining measurement accuracy achieving specifications for safety-critical applications.

- Power Quality Analysis: FFT algorithms calculating harmonic content through 40th harmonic, detecting power factor, and identifying disturbances supporting predictive maintenance and grid compatibility validation.

- Multi-Channel Synchronization: Simultaneous sampling across multiple measurement channels preventing phase errors in three-phase systems enabling accurate power calculations and load balancing optimization.

- Calibration and Compensation: Factory calibration storing correction factors in non-volatile memory compensating for component tolerances and temperature drift maintaining long-term accuracy through testing quality validation protocols.

Validated Measurement Accuracy

By combining precision components, advanced signal processing, and comprehensive calibration procedures supported by our quality systems, APTPCB enables power control boards achieving IEC 62053-22 Class 0.5S accuracy specifications supporting revenue-grade metering, energy management optimization, and compliance with international standards across diverse industrial and commercial applications.

Implementing Reliable Multi-Channel Load Switching

Power control boards must reliably switch multiple loads ranging from resistive heaters through inductive motors across millions of switching cycles while preventing contact welding, maintaining low contact resistance, and coordinating switching sequences preventing overload conditions. Contact degradation from insufficient derating, improper snubber design, or inadequate thermal management causes premature failures requiring expensive field replacements and system downtime.

At APTPCB, our manufacturing implements validated switching circuits ensuring long-term reliability.

Key Switching Implementation Techniques

- Relay Selection and Integration: Automotive or industrial-grade relays rated 2-3× steady-state current with proper coil voltage regulation preventing undervoltage or overvoltage conditions affecting contact life expectancy.

- Solid-State Switching Options: TRIAC, SCR, or MOSFET-based switches for applications requiring silent operation, high-speed switching, or extended lifetime eliminating mechanical contact wear in demanding applications.

- Snubber Circuit Design: RC or RCD snubbers limiting voltage transients during inductive load switching preventing contact arcing and voltage spikes potentially damaging sensitive electronics or control circuits.

- Zero-Crossing Detection: Synchronizing switching operations with AC voltage zero-crossings minimizing inrush current and electromagnetic interference improving system reliability and electromagnetic compatibility.

- Sequential Startup Control: Staggered load energization preventing simultaneous inrush limiting peak demand charges and preventing nuisance trips of upstream protection devices.

- Contact Monitoring and Diagnostics: Current sensing and feedback circuits detecting stuck or welded contacts enabling predictive maintenance preventing unexpected system failures through functional testing validation during production.

Proven Switching Reliability

Through proper component selection, validated circuit design, and comprehensive life testing coordinated with our manufacturing processes, APTPCB delivers power control boards achieving >10 million mechanical switching cycles or >100,000 hours solid-state operation supporting reliable load management across industrial automation, HVAC control, and energy management applications.

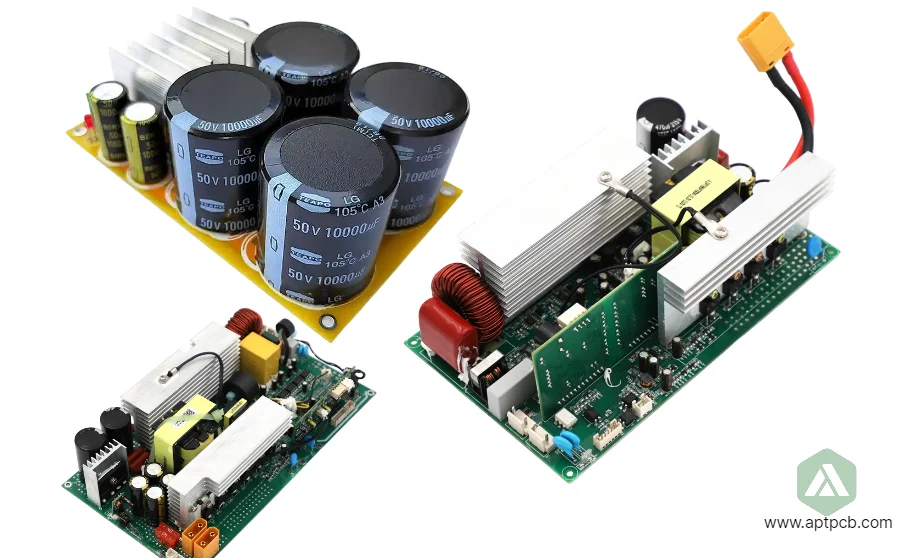

Managing Thermal Challenges in High-Current Control Applications

Power control boards handling hundreds of amperes dissipate significant heat from relay coils, switching semiconductors, current shunts, and power supply circuits requiring comprehensive thermal management preventing component overheating causing premature aging, false trips, or catastrophic failures. Insufficient thermal design creates hot spots exceeding component ratings, accelerating electrolytic capacitor aging, and degrading relay contact performance — directly impacting system reliability and maintenance costs.

At APTPCB, our assembly integrates validated thermal strategies ensuring safe continuous operation.

Key Thermal Management Techniques

- Heavy Copper PCB Construction: 4-6oz copper thickness in power distribution layers spreading heat across board area while handling high continuous currents with quality system controls ensuring consistent copper weight specifications.

- Strategic Component Placement: Separating heat-generating devices (relays, regulators, shunts) preventing thermal coupling while optimizing natural convection or forced air cooling effectiveness.

- Thermal Via Arrays: Dense via patterns beneath power components transferring heat through PCB to heat sinks or opposite side improving thermal dissipation in double-sided assemblies.

- Heat Sink Integration: Properly sized extruded aluminum or copper heat sinks with thermal interface materials maintaining semiconductor junction temperatures within specifications during sustained operation.

- Temperature Monitoring: Embedded NTC thermistors or digital temperature sensors enabling thermal derating, over-temperature protection, and predictive maintenance through continuous monitoring.

- Thermal Simulation Validation: Pre-production CFD analysis predicting component temperatures under worst-case conditions validating thermal design before committing to tooling and production.

Thermally Robust Design Implementation

By implementing comprehensive thermal analysis, validated heat sink designs, and temperature monitoring capabilities supported by NPI assembly prototyping services, APTPCB enables power control boards maintaining safe operating temperatures throughout extended service lives supporting reliable continuous operation in demanding industrial and commercial environments.

Enabling Smart Grid and IoT Connectivity

Modern power control systems require robust communication capabilities integrating with building management systems, SCADA networks, cloud platforms, and mobile applications enabling remote monitoring, automated control, and data analytics. Communication interface implementation must balance functionality against security, reliability, and cost while supporting industry-standard protocols ensuring interoperability across diverse system architectures.

At APTPCB, our assembly services integrate validated communication interfaces supporting intelligent power management.

Key Communication Implementation Techniques

- Industrial Protocol Support: Modbus RTU/TCP, BACnet, LonWorks, or KNX integration enabling seamless connection to building automation and industrial control systems supporting standardized device discovery and configuration.

- Wireless Connectivity Options: WiFi, Zigbee, LoRaWAN, or cellular (4G/5G) modules providing remote access and monitoring in applications where wired connections impractical or cost-prohibitive.

- Cybersecurity Implementation: Secure boot, encrypted communications (TLS/SSL), and access control preventing unauthorized system access protecting critical infrastructure from cyber threats.

- Cloud Platform Integration: MQTT or REST APIs enabling data streaming to cloud platforms supporting real-time monitoring, historical analysis, and machine learning-based optimization algorithms.

- Local HMI Interfaces: LCD displays, status LEDs, and button inputs providing local visibility and control supporting commissioning, troubleshooting, and manual override functionality.

- Firmware Update Capability: Over-the-air (OTA) or field-programmable firmware updates enabling feature additions, bug fixes, and security patches throughout product lifecycle through mass production support services.

Connected Power Management Solutions

Through comprehensive communication protocol support, secure implementation practices, and flexible interface options, APTPCB enables power control manufacturers deploying IoT-connected solutions supporting smart building automation, industrial energy management, and grid modernization initiatives across global markets.

Providing Comprehensive Protection and Safety Features

Power control boards managing critical loads require multi-layer protection preventing damage from overcurrent, overvoltage, undervoltage, ground faults, and communication failures while maintaining safe operation despite component or software malfunctions. Protection implementation must coordinate with upstream devices, provide user-adjustable thresholds, and maintain UL, CE, or IEC compliance enabling global market access.

At APTPCB, our manufacturing implements validated protection circuits ensuring safe reliable operation.

Key Protection Implementation Techniques

- Overcurrent Protection: Hardware current sensing with adjustable trip thresholds coordinating with upstream circuit breakers preventing nuisance trips while protecting against sustained overload or short circuit conditions.

- Voltage Monitoring: Under-voltage and over-voltage detection with adjustable hysteresis preventing load damage from supply variations triggering controlled shutdown or load disconnection during fault conditions.

- Ground Fault Detection: Residual current monitoring identifying leakage currents indicating insulation failures preventing shock hazards in safety-critical applications meeting electrical code requirements.

- Thermal Protection: Temperature-based derating and shutdown preventing component damage during high ambient temperatures or cooling system failures enabling graceful degradation rather than catastrophic failure.

- Watchdog Monitoring: Independent hardware watchdog circuits detecting software hang or communication loss triggering safe-state transitions preventing uncontrolled operation during system malfunctions.

- Arc Flash Prevention: Current limiting and rapid disconnection during fault conditions minimizing arc flash hazards in high-voltage installations protecting personnel and equipment through component sourcing of safety-rated components.

Multi-Layer Safety Assurance

Through comprehensive protection circuit implementation, validated coordination studies, and compliance testing supported by our quality management systems, APTPCB delivers power control boards meeting international safety standards supporting deployment in commercial buildings, industrial facilities, and utility infrastructure worldwide.

Supporting Diverse Application Markets and Customization

Power control boards serve diverse applications including building automation (lighting, HVAC, elevator control), renewable energy (solar MPPT, battery management), industrial processes (motor control, heating), and smart grid (demand response, load shedding) requiring application-specific optimizations in control algorithms, interface protocols, environmental ratings, and certification requirements.

At APTPCB, we provide flexible manufacturing supporting diverse customization requirements through modular designs and comprehensive engineering support.

Key Application Support Capabilities

Building Automation Integration

- BACnet or KNX protocol support enabling integration with commercial building management systems supporting centralized monitoring and control.

- DIN rail or wall-mount form factors accommodating standard electrical panel installations supporting diverse mounting requirements.

- Scheduling and occupancy-based control implementing energy-saving algorithms reducing operational costs through intelligent load management.

- Integration with lighting control, HVAC systems, and access control providing comprehensive building automation solutions.

- Local and remote override capability supporting manual operation during maintenance or emergency conditions.

Industrial and Renewable Energy

- Ruggedized construction surviving harsh environments (-40 to +85°C) with conformal coating protecting against humidity and contamination through PCB conformal coating processes.

- Three-phase power monitoring and control supporting industrial motor drives, transformer monitoring, and generator management applications.

- MPPT algorithms and battery charge control supporting solar installations and energy storage systems maximizing renewable energy utilization.

- Predictive maintenance algorithms analyzing power consumption patterns identifying equipment degradation before failures occur.

- Industrial certification support (UL508, CE, IECEx) enabling deployment in hazardous locations and global industrial facilities.

Through application-optimized designs, flexible manufacturing platforms, and comprehensive engineering support coordinated with special PCB manufacturing capabilities, APTPCB enables power control manufacturers deploying intelligent power management solutions across diverse commercial, industrial, and utility markets supporting energy efficiency, grid modernization, and operational optimization worldwide.