Power distribution board PCBs manage electrical power distribution across industrial control panels, telecommunications central offices, data centers, and building management systems handling currents from 50A through 1000A+ with integrated protection (fuses, circuit breakers), monitoring (voltage, current, temperature sensors), and control features (relay switching, remote management) requiring heavy copper construction, robust connectors, and reliable operation supporting critical infrastructure through 15-25 year service lives.

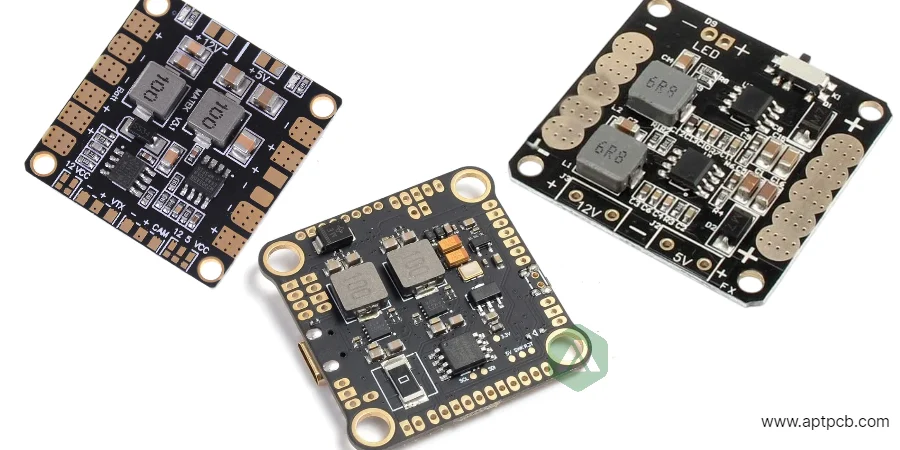

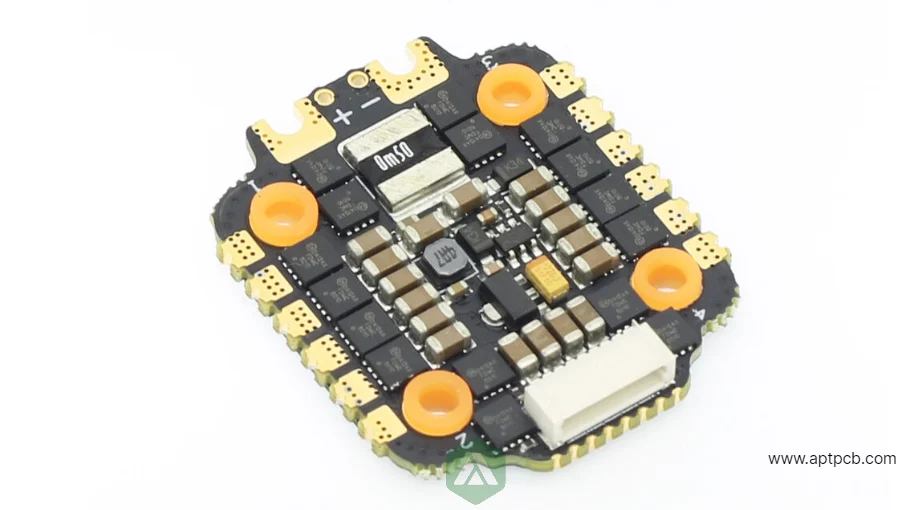

At APTPCB, we manufacture power distribution PCBs with heavy copper capabilities (4-10oz), busbar integration, and industrial-grade components. Our high thermal PCB expertise supports high-current applications requiring superior heat dissipation across voltage ranges from 12-48VDC telecommunications through 480VAC industrial three-phase distribution.

Managing High-Current Distribution

Multi-hundred ampere current distribution requires heavy copper PCB construction, proper trace width calculations, busbar integration, and thermal management preventing excessive temperature rise causing PCB delamination, connector degradation, or component failures. Inadequate current handling design causes resistive heating, voltage drops affecting connected equipment, or catastrophic failures from conductor melting or arc flash.

At APTPCB, our manufacturing implements validated high-current distribution designs.

Key High-Current Design Requirements

Heavy Copper PCB Construction

- 4-10oz copper thickness in power distribution layers handling continuous high currents with metal core PCB options for highest thermal performance

- Trace width calculations accounting for temperature rise limits (typically 10-30°C above ambient)

- Current derating for internal layers considering limited heat dissipation

- Via arrays distributing current between layers reducing resistance and hot spots

- Plated through-holes or heavy copper vias handling layer-to-layer current transfer

- Thermal simulation validating designs maintain safe copper temperatures

Busbar Integration Methods

- Copper busbar mounting using bolted connections achieving low-resistance interfaces

- PCB-integrated busbars formed from heavy copper PCB material

- Flexible busbar connections accommodating thermal expansion and vibration

- Proper torque specifications ensuring consistent contact resistance

- Surface treatment preventing oxidation maintaining low contact resistance

- Testing validation measuring resistance and temperature rise under rated current

Providing Protection and Monitoring

Distribution boards integrate overcurrent protection (fuses, circuit breakers), monitoring sensors (current, voltage, temperature), and status indication enabling comprehensive power management. Protection coordination ensures proper clearing of faults while monitoring provides operational visibility supporting predictive maintenance and optimization.

APTPCB manufactures distribution boards with integrated protection and monitoring.

Protection and Monitoring Integration

Overcurrent Protection

- Fuse holders or circuit breaker mounting accommodating branch circuit protection

- Protection coordination ensuring proper fault clearing without nuisance trips

- Indicator LEDs or status signals showing protection device state

- Remote monitoring interfaces communicating protection status

- Replacement accessibility enabling maintenance without extended downtime

- Thermal management preventing protection device heating affecting operation

Current and Voltage Monitoring

- Hall effect current sensors or shunt resistors measuring branch currents

- Voltage sensing circuits monitoring bus voltage and branch outputs

- Temperature sensors detecting hot spots or thermal issues

- Microcontroller or monitoring IC processing sensor data

- Communication interfaces (Modbus, Ethernet, RS-485) reporting telemetry

- Alarm outputs triggering external systems during abnormal conditions

Enabling Scalable and Modular Architectures

Distribution board designs must accommodate varying load counts, current ratings, and voltage configurations supporting diverse installations from small control panels through large data center or telecommunications facilities. Modular architectures enable customization without complete redesign reducing engineering costs and time-to-market.

APTPCB supports modular distribution board manufacturing.

Modular Design Implementation

Scalable Architecture

- Common backplane or bus structure supporting variable module counts

- Plug-in branch modules enabling field configuration and expansion

- Standardized mounting enabling mechanical interchangeability

- Communication bus allowing inter-module coordination and monitoring

- Power module redundancy supporting N+1 or 2N configurations

- Field-replaceable modules enabling maintenance without system shutdown

Connector and Interface Standards

- High-current connectors rated for continuous operation at rated current

- Keyed connectors preventing incorrect insertion or reverse polarity

- Locking mechanisms maintaining secure connections despite vibration

- Touch-safe construction preventing accidental contact with live conductors

- Labeling and documentation supporting installation and maintenance

- Testing validation confirming connector resistance and temperature rise

Supporting Critical Infrastructure Applications

Power distribution boards serve mission-critical applications including telecommunications central offices, data centers, hospital electrical systems, and industrial control panels requiring high availability (>99.99% uptime), redundancy features, remote monitoring, and validated reliability supporting uninterrupted operation of critical loads.

APTPCB provides manufacturing supporting critical infrastructure requirements.

Critical Application Features

High Availability Design

- Redundant power paths enabling continued operation despite single failures

- Hot-swap capability allowing module replacement without system shutdown

- Battery backup coordination supporting seamless failover during outages

- Predictive monitoring enabling proactive maintenance before failures

- Detailed documentation supporting rapid troubleshooting and repair

- Spare module inventory strategies minimizing downtime during failures

Industry Standards Compliance

- NEBS Level 3 for telecommunications central office equipment

- UL 508A for industrial control panels

- IEC 61439 for low-voltage switchgear and control gear assemblies

- Data center standards (TIA-942) for computing infrastructure

- Seismic qualification for installations in earthquake zones

- Fire ratings meeting building code requirements for installed locations

Delivering Ruggedized Industrial Construction

Distribution boards installed in industrial environments face harsh conditions including temperature extremes, humidity, dust, vibration, and corrosive atmospheres requiring ruggedized construction, environmental protection, and validated qualification testing ensuring 15-25 year service lives matching facility infrastructure lifetimes.

APTPCB implements industrial-grade manufacturing ensuring long-term reliability.

Industrial Construction Requirements

Environmental Protection

- Conformal coating protecting circuits from humidity and contamination

- Sealed connectors preventing moisture and dust ingress

- Corrosion-resistant finishes surviving industrial atmospheres

- Wide temperature range components (-40 to +85°C) surviving extremes

- Vibration-resistant mounting and component attachment

- IP-rated enclosures when required for exposed installations

Quality and Reliability

- Industrial-grade components rated for extended lifetimes

- Rigorous burn-in and environmental stress screening

- Accelerated life testing predicting field reliability

- Comprehensive documentation supporting long-term supportability

- Manufacturing traceability enabling failure analysis and improvement

- Warranty and support programs backing long-term performance commitments

Through ruggedized construction, comprehensive testing, and quality management coordinated with PCB quality standards, APTPCB enables power distribution board manufacturers deploying reliable solutions supporting critical infrastructure across telecommunications, data centers, and industrial facilities worldwide.

Providing Manufacturing and Engineering Support

Power distribution board projects require close engineering collaboration optimizing designs for manufacturing, cost, and reliability while meeting application-specific requirements for current capacity, protection coordination, monitoring features, and mechanical integration.

APTPCB delivers comprehensive manufacturing and engineering support.

Support Services

Engineering Collaboration

- DFM review optimizing designs for manufacturing and cost

- Current capacity analysis validating thermal performance

- Protection coordination studies ensuring proper fault clearing

- Mechanical integration support for enclosure and mounting

- Testing and qualification support throughout development

- Ongoing support throughout product lifecycle

Through comprehensive engineering support, flexible manufacturing, and proven quality systems coordinated with PCB fabrication process controls, APTPCB enables successful power distribution board programs supporting critical infrastructure applications globally.