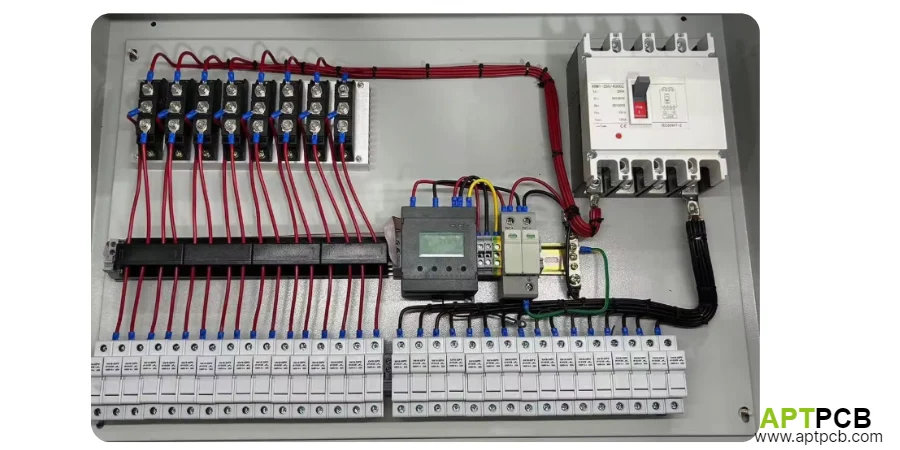

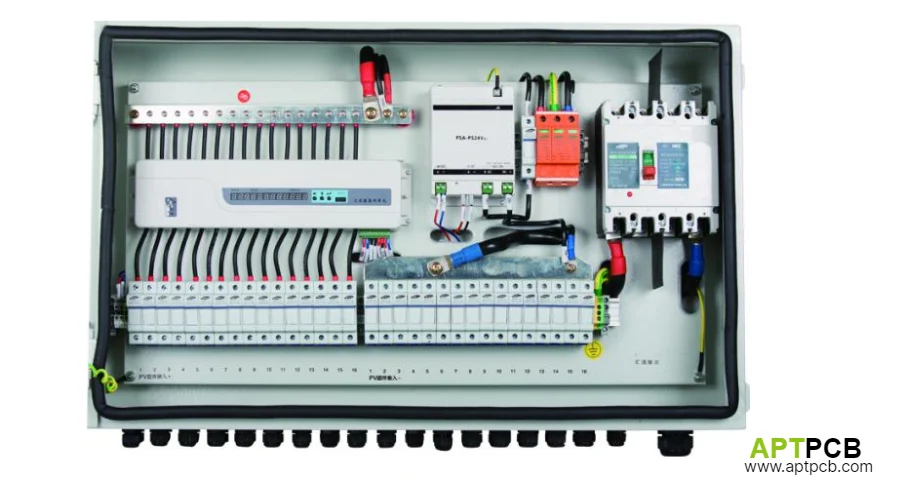

PV DC combiner PCBs consolidate multiple solar string outputs into common DC bus connections managing high voltages (600-1500VDC) with integrated monitoring, overcurrent protection, and surge suppression. These boards serve as critical distribution points in commercial and utility-scale solar installations requiring robust high-voltage design, environmental durability, and 25+ year operational lifetimes matching system warranties.

At APTPCB, we manufacture PV combiner PCBs implementing high-voltage design rules, protection circuits, and monitoring capabilities. Our manufacturing expertise supports utility-scale installations requiring reliable DC power management and comprehensive string monitoring.

Implementing High-Voltage DC Design and Safety

PV combiner boards handle DC voltages up to 1500V requiring enhanced creepage, clearance, and material selection preventing electrical breakdown or arc flash hazards. High-voltage design errors create life-safety risks and certification failures with serious consequences.

At APTPCB, our manufacturing implements stringent high-voltage design rules and process controls.

Key High-Voltage Design Requirements

- Enhanced Spacing Rules: Creepage and clearance distances per IEC 62109 and UL 1741 maintaining minimum separation between high-voltage conductors.

- Isolation Implementation: Multilayer PCB construction with dedicated isolation layers achieving reinforced isolation between DC strings and monitoring circuits.

- Material Selection: High-CTI laminate materials (>400V) preventing carbon tracking and maintaining insulation resistance in outdoor humidity.

- Soldermask Protection: Enhanced soldermask thickness providing dielectric barrier and environmental protection for high-voltage traces.

- Partial Discharge Testing: Manufacturing qualification through corona testing ensuring designs withstand continuous high-voltage stress without degradation.

- Arc Flash Protection: Design features and component spacing minimizing arc flash energy in fault conditions protecting personnel and equipment.

Electrical Safety Compliance

Through high-voltage manufacturing expertise and PCB fabrication processes, APTPCB delivers combiner PCBs maintaining electrical safety throughout 25+ year operational lifetimes in utility-scale installations.

Integrating String Current Monitoring and Management

Modern PV combiners provide individual string current monitoring enabling performance optimization, fault detection, and predictive maintenance. Monitoring implementation requires precision current sensing, communication interfaces, and integration with plant SCADA systems.

APTPCB manufactures combiner boards with comprehensive monitoring capabilities.

Key Monitoring Implementation

- String Current Sensing: Hall-effect or shunt-based current measurement for each string with ±1% accuracy enabling performance monitoring and fault detection.

- Voltage Monitoring: String and bus voltage measurement validating proper operation and detecting ground faults or arc faults.

- Temperature Monitoring: Ambient and component temperature sensing enabling thermal management and identifying connection resistance issues.

- Communication Integration: RS-485, Modbus, or Ethernet interfaces transmitting monitoring data to plant SCADA systems for centralized management.

- Data Processing: Microcontroller integration processing sensor data, implementing algorithms, and managing communication protocols.

- Alarm Generation: Configurable thresholds triggering alarms for overcurrent, undervoltage, or temperature conditions enabling rapid response.

Enhanced System Visibility

By integrating monitoring through BGA QFN assembly and validated testing, APTPCB enables combiner systems providing comprehensive visibility improving plant performance and uptime.

Providing Overcurrent Protection and Fusing

PV string protection requires overcurrent detection and isolation preventing fault currents from damaging panels, wiring, or inverters. Protection implementation includes fusing, circuit breakers, and fault detection logic ensuring rapid isolation while minimizing false trips.

APTPCB manufactures combiner boards with integrated protection systems.

Key Protection Implementation

- String Fusing: PCB-mounted fuse holders or integrated circuit breakers providing overcurrent protection for each string input.

- Fuse Rating Selection: Proper fuse selection balancing string protection with minimizing nuisance trips from normal irradiance variations.

- Arc Flash Detection: Optional arc fault detection circuits identifying dangerous arcing conditions triggering rapid shutdown.

- Ground Fault Detection: Monitoring circuit detecting insulation failures enabling rapid response preventing equipment damage or fire hazards.

- Surge Protection: Integrated surge suppression devices protecting electronics from lightning-induced transients common in outdoor installations.

- Bypass Options: Fused string bypass capabilities enabling continued operation during maintenance or string failures.

Comprehensive String Protection

Through integrated protection and validated manufacturing, APTPCB delivers combiner assemblies protecting expensive solar assets and ensuring safe operation throughout system lifetime.

Ensuring Environmental Durability for Outdoor Installations

PV combiner boxes operate in harsh outdoor environments—rooftop installations, desert locations, coastal regions—experiencing temperature extremes, humidity, dust, and UV exposure requiring enhanced environmental protection and material selection.

APTPCB implements comprehensive protection for outdoor power electronics.

Key Environmental Protection Methods

- High-Temperature Materials: High-Tg PCB laminates maintaining dimensional stability and electrical performance during continuous elevated temperature operation.

- Corrosion-Resistant Finishes: Enhanced surface treatments providing superior corrosion resistance in coastal or industrial environments.

- UV-Resistant Soldermask: Soldermask formulations resisting UV degradation maintaining mechanical properties and color despite continuous sunlight exposure.

- Moisture Protection: Conformal coating or potting options protecting circuits from humidity and condensation in sealed outdoor enclosures.

- Wide Temperature Range: Component selection supporting -40°C to +85°C operation across diverse geographic installations.

- Environmental Testing: Accelerated humidity, thermal cycling, and salt spray qualification validating 25-year outdoor lifetime predictions.

Decades of Field Reliability

Through environmental protection and special PCB manufacturing, APTPCB delivers combiner PCBs surviving extended outdoor operation in diverse climates.

Executing Production Testing and Quality Validation

PV combiner validation requires testing high-voltage insulation, protection circuits, monitoring accuracy, and communication interfaces ensuring reliable operation before field deployment. Comprehensive testing prevents costly field failures and safety incidents.

APTPCB provides dedicated high-voltage test capabilities.

Key Testing Requirements

- Hi-Pot Testing: Dielectric withstand testing verifying insulation integrity between high-voltage sections and monitoring circuits.

- Insulation Resistance: Measuring insulation resistance confirming proper isolation meeting safety standards and certification requirements.

- Current Sensing Validation: Verifying monitoring accuracy across operating current ranges with calibrated instrumentation.

- Protection Circuit Testing: Triggering overcurrent, ground fault, and arc fault conditions verifying proper protective responses.

- Communication Testing: Validating RS-485, Modbus, or Ethernet interfaces ensuring reliable data transmission.

- Environmental Stress: Temperature cycling and thermal shock testing identifying manufacturing defects before shipment.

Validated Safety and Performance

Through comprehensive testing with quality system controls, APTPCB delivers combiner PCBs meeting safety standards and performance specifications supporting successful utility-scale deployments.

Supporting Scalable Production for Solar Installations

PV combiner requirements span small commercial installations through utility-scale solar farms requiring manufacturing flexibility supporting diverse specifications, certifications, and volume requirements from hundreds to thousands of units.

APTPCB provides scalable manufacturing from prototypes through volume production.

Key Production Capabilities

- Custom Configurations: Flexible manufacturing accommodating string counts, voltage ratings, and monitoring features serving specific project requirements.

- Rapid Prototyping: NPI small batch production delivering evaluation units supporting project bidding and engineering validation.

- Volume Production: Mass production capability supporting utility-scale projects requiring thousands of combiner assemblies with consistent quality.

- Certification Support: Manufacturing documentation and testing supporting UL, CE, and regional certifications enabling global installations.

- Supply Chain Management: Component procurement ensuring availability of specialized high-voltage components and fusing devices.

- Technical Support: Engineering assistance with high-voltage design, protection coordination, and manufacturing throughout project lifecycle.

Reliable Solar Infrastructure Partnership

Through scalable capabilities and responsive support, APTPCB enables solar developers and EPCs deploying reliable DC power management infrastructure. Our power energy experience supports successful utility-scale solar projects globally.