Key Takeaways

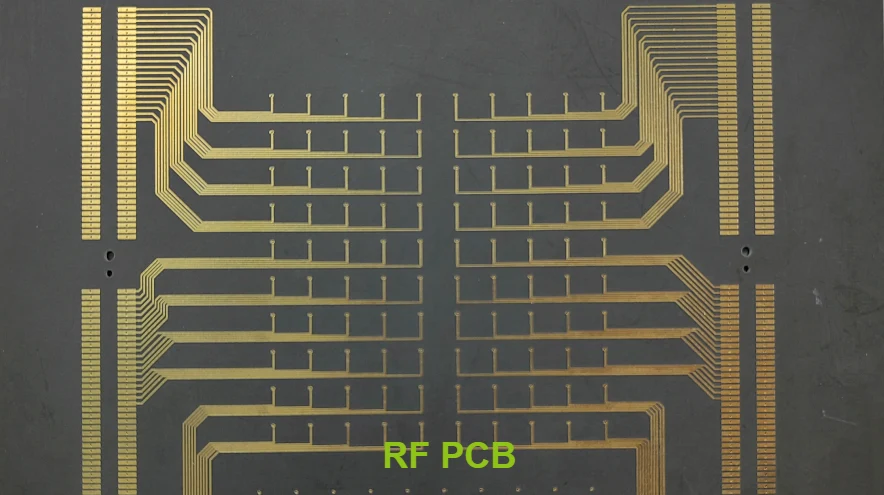

- Definition: An RF Generator PCB is the core circuit board responsible for creating, modulating, and amplifying radio frequency signals in test equipment, industrial heating, and communication systems.

- Critical Metrics: Signal integrity relies heavily on Dissipation Factor (Df), Dielectric Constant (Dk) stability, and thermal management.

- Technology Shift: Modern designs often utilize DDS Generator PCB (Direct Digital Synthesis) architecture for higher precision compared to traditional analog oscillators.

- Material Selection: Standard FR4 is often insufficient for frequencies above 1GHz; PTFE or ceramic-filled hydrocarbon laminates are required to minimize insertion loss.

- Validation: Manufacturing success is measured by Impedance Control accuracy (typically ±5% or ±10%) and Time Domain Reflectometry (TDR) testing.

- Common Pitfall: Neglecting the "skin effect" and surface roughness of copper foil can lead to unexpected signal attenuation in high-frequency applications.

What RF Generator PCB really means (scope & boundaries)

To understand how to manufacture these boards, we must first define the operational scope of an RF Generator PCB. Unlike standard logic boards, these PCBs are active sources of energy. They do not just route signals; they create them. This category encompasses a wide range of applications, from a simple Audio Generator PCB used in low-frequency acoustic testing to a complex BER Generator PCB (Bit Error Rate) used for validating high-speed data links.

The primary function of an RF Generator PCB is to maintain a stable frequency and amplitude under varying load conditions. In the past, an Analog Generator PCB relied on LC tank circuits and crystal oscillators. While these are still used for low-noise applications, the industry has largely shifted toward digital synthesis. A DDS Generator PCB uses a digital-to-analog converter to generate waveforms, requiring a PCB layout that isolates noisy digital clocks from sensitive analog output stages.

At APTPCB (APTPCB PCB Factory), we categorize these boards based on their power and frequency requirements. A Clock Generator PCB might require extreme phase noise performance but low power, whereas an industrial RF plasma generator requires high thermal dissipation capabilities. Understanding these boundaries is the first step in selecting the right manufacturing process.

RF Generator PCB metrics that matter (how to evaluate quality)

Once the scope is defined, you must quantify performance using specific metrics. The following table outlines the physical and electrical properties that directly impact the quality of an RF Generator PCB.

| Metric | Why it matters | Typical Range / Factor | How to Measure |

|---|---|---|---|

| Dielectric Constant (Dk) | Determines signal propagation speed and impedance trace width. Variations cause impedance mismatches. | 2.2 (PTFE) to 4.5 (FR4). Tight tolerance (±0.05) is preferred. | IPC-TM-650 2.5.5.5 (Strip-line method). |

| Dissipation Factor (Df) | Controls signal loss (attenuation). High Df turns signal energy into heat. | < 0.003 for High Frequency; < 0.02 for Standard FR4. | Cavity Resonator method. |

| Coefficient of Thermal Expansion (CTE-z) | Critical for plated through-hole (PTH) reliability during soldering and operation. | < 50 ppm/°C (z-axis) is ideal to prevent via cracking. | TMA (Thermomechanical Analysis). |

| Copper Surface Roughness | Rough copper increases resistance at high frequencies due to the skin effect. | VLP (Very Low Profile) or HVLP copper (< 2µm roughness). | Profilometer or SEM analysis. |

| Peel Strength | Ensures traces do not lift, especially on PTFE materials which are notoriously difficult to bond. | > 0.8 N/mm (Standard); > 1.05 N/mm (High reliability). | IPC-TM-650 2.4.8. |

| Thermal Conductivity | Essential for power amplifiers on the generator board to dissipate heat. | 0.3 W/mK (FR4) to 3.0+ W/mK (Metal Core/Ceramic). | Laser Flash method. |

How to choose RF Generator PCB: selection guidance by scenario (trade-offs)

Understanding the metrics allows you to make informed decisions based on your specific application scenario. Below are common scenarios for RF Generator PCB selection and the necessary trade-offs.

1. High-Precision Lab Equipment (DDS Focus)

- Scenario: You are designing a signal generator for a calibration lab.

- Priority: Phase noise and frequency stability.

- Trade-off: You must sacrifice cost for materials. Use Rogers or Taconic laminates. A hybrid stackup (RF material on top, FR4 for digital logic) is often the best balance.

- Selection: Choose materials with stable Dk over a wide temperature range.

2. Industrial Heating/Plasma Generation

- Scenario: The PCB drives a 13.56 MHz RF source for semiconductor manufacturing.

- Priority: Power handling and thermal management.

- Trade-off: Signal integrity is secondary to thermal survival.

- Selection: Use Heavy Copper PCB technology (2oz or 3oz copper) and potentially a metal core substrate to sink heat away from power transistors.

3. Portable Field Test Equipment

- Scenario: A battery-operated Clock Generator PCB for field diagnostics.

- Priority: Size and weight (SWaP).

- Trade-off: Thermal management becomes difficult in small spaces.

- Selection: High-density Interconnect (HDI) techniques are required. Use thinner dielectrics to reduce overall board thickness, but ensure impedance lines are recalculated for the thinner stackup.

4. High-Speed Data Testing (BER)

- Scenario: A BER Generator PCB creating pseudo-random bit sequences at 25 Gbps+.

- Priority: Signal rise time and minimal jitter.

- Trade-off: Manufacturing tolerance must be extremely tight.

- Selection: Requires Back-drilling to remove via stubs that cause signal reflections. Surface finish must be ENIG or Immersion Silver (flat) rather than HASL.

5. Audio Frequency Generation

- Scenario: An Audio Generator PCB for acoustic analysis (20Hz - 20kHz).

- Priority: Low noise floor and harmonic distortion (THD).

- Trade-off: RF materials are unnecessary and wasteful.

- Selection: High-quality FR4 is sufficient. Focus on layout (star grounding) rather than exotic materials.

6. Aerospace/Defense Signal Source

- Scenario: Radar signal generation.

- Priority: Reliability under vibration and extreme temperature cycling.

- Trade-off: Lead times are longer due to certification requirements.

- Selection: Materials must meet outgassing requirements. Polyimide or high-Tg FR4 combined with RF laminates is common.

RF Generator PCB implementation checkpoints (design to manufacturing)

After selecting the right approach for your scenario, the project moves to the implementation phase. APTPCB recommends the following checkpoints to ensure the design intent survives the manufacturing process.

Stackup Verification:

- Recommendation: Confirm the layer stackup with the fab house before routing.

- Risk: If the fab house does not stock the specific prepreg thickness you simulated, your impedance will be wrong.

- Acceptance: Signed stackup sheet from the CAM engineer.

Material Availability Check:

- Recommendation: Check stock for specific high-frequency laminates (e.g., Rogers 4350B, Isola I-Speed).

- Risk: RF materials often have 4-8 week lead times.

- Acceptance: Material datasheet and stock confirmation.

Impedance Trace Width Compensation:

- Recommendation: Allow the manufacturer to adjust trace widths slightly (<10%) to hit target impedance based on their specific etch factors.

- Risk: Strict "do not modify" instructions may result in failed impedance tests due to real-world etching variables.

- Acceptance: Impedance Control report simulation.

Via Design and Back-drilling:

- Recommendation: Identify high-speed vias that require back-drilling to remove stubs.

- Risk: Unwanted stubs act as antennas, causing resonance and signal degradation.

- Acceptance: Drill files clearly marking back-drill locations.

Copper Surface Profile:

- Recommendation: Specify VLP (Very Low Profile) copper foil for frequencies >1GHz.

- Risk: Standard copper roughness increases insertion loss significantly at microwave frequencies.

- Acceptance: Material certification specifying foil type.

Solder Mask Application:

- Recommendation: Remove solder mask from high-frequency transmission lines if possible, or account for the mask's Dk in simulation.

- Risk: Solder mask adds capacitance and dielectric loss.

- Acceptance: Gerber files showing mask clearance or specific "LPI" thickness requirements.

Thermal Management Strategy:

- Recommendation: For high-power generators, ensure thermal vias are plugged and capped (VIPPO) if placed in pads.

- Risk: Solder wicking into open vias leads to poor component connection and thermal failure.

- Acceptance: Section analysis showing filled vias.

Surface Finish Selection:

- Recommendation: Use ENIG (Electroless Nickel Immersion Gold) or Immersion Silver.

- Risk: HASL is too uneven for fine-pitch components and has poor RF characteristics.

- Acceptance: Visual inspection and thickness measurement (X-Ray Fluorescence).

Cleanliness and Etching:

- Recommendation: Strict etching tolerances are required to maintain phase balance in differential pairs.

- Risk: Over-etching increases impedance; under-etching decreases it.

- Acceptance: AOI (Automated Optical Inspection) reports.

Final Profiling:

- Recommendation: Use routing rather than V-scoring for RF boards to avoid mechanical stress on ceramic-filled materials.

- Risk: Ceramic materials are brittle and can fracture during V-score separation.

- Acceptance: Dimensional check.

RF Generator PCB common mistakes (and the correct approach)

Even with strict checkpoints, errors can occur. Here are common mistakes specific to RF Generator PCB projects and how to avoid them.

- Mistake: Mixing incompatible materials in hybrid stackups.

- Correction: When bonding FR4 with PTFE (Teflon), their CTE (expansion rates) differ. This can cause delamination during reflow. Always use high-Tg FR4 that is compatible with the cure cycle of the RF material, or consult RF Rogers material guides for bonding ply recommendations.

- Mistake: Ignoring the return path.

- Correction: RF signals travel as electromagnetic fields between the trace and the reference plane. If the reference plane is split or interrupted by a via fence, the return path loop area increases, causing inductance and EMI. Always maintain a solid ground plane underneath RF traces.

- Mistake: Placing noisy components near the VCO.

- Correction: In a DDS Generator PCB, the Voltage Controlled Oscillator (VCO) is sensitive. Placing a switching power supply or digital clock buffer nearby will couple noise into the RF output. Use shielding cans and physical separation.

- Mistake: Over-specifying tolerances.

- Correction: Demanding ±1% impedance tolerance is often impossible or prohibitively expensive. Standard high-end manufacturing achieves ±5%. Design your circuit to tolerate ±5% or ±10% variation.

- Mistake: Neglecting connector transitions.

- Correction: The transition from the SMA/BNC connector to the PCB trace is a major source of reflection. Use a tapered landing pad design and simulate the launch footprint.

- Mistake: Using standard FR4 for >2GHz applications.

- Correction: While FR4 works for an Audio Generator PCB, its Df is too high and inconsistent for RF. The signal will attenuate rapidly. Use materials specifically designed for High Frequency PCB applications.

RF Generator PCB FAQ (cost, lead time, materials, testing, acceptance criteria)

Q: What are the primary cost drivers for an RF Generator PCB? A: The biggest cost driver is the laminate material (Rogers/Taconic can be 5-10x the cost of FR4). Other factors include the number of layers, the need for back-drilling, blind/buried vias, and hard gold plating for edge connectors.

Q: How does the lead time for RF Generator PCBs compare to standard boards? A: Standard FR4 boards can be produced in 24-48 hours. However, RF boards often require 5-15 days. This is due to the procurement time for specialized laminates and the slower, more careful etching and lamination processes required for ceramic-filled materials.

Q: Can I use a hybrid stackup (FR4 + RF Material) to save money? A: Yes, this is a standard practice. We often use a core of expensive RF material for the top signal layer and cheaper FR4 for the remaining power and control layers. This reduces total material cost while maintaining signal integrity.

Q: What specific testing is required for an RF Generator PCB? A: Beyond standard E-test (Open/Short), RF boards require TDR (Time Domain Reflectometry) to verify impedance coupons. For ultra-high reliability, VNA (Vector Network Analyzer) testing may be performed on test structures to verify insertion loss.

Q: What are the acceptance criteria for RF PCB manufacturing? A: Most RF boards are built to IPC-6012 Class 2 or Class 3 standards. Key acceptance criteria include impedance tolerance (usually ±5% or ±10%), plating thickness, and the absence of copper voids in high-frequency paths.

Q: How do I choose between an Analog Generator PCB and a DDS Generator PCB? A: Choose Analog if you need the absolute lowest spurious noise and a "clean" sine wave for simple applications. Choose DDS if you need rapid frequency hopping, precise digital control, and complex waveform generation.

Q: Does the surface finish affect RF performance? A: Yes. HASL (solder) is uneven and poor for RF. ENIG is better, but the nickel layer has magnetic properties that can increase loss at very high frequencies. Immersion Silver or OSP (Organic Solderability Preservative) are often preferred for the highest frequency applications due to lower loss.

Q: What information is needed for a quote? A: We need the Gerber files, a drill file, and a detailed fabrication drawing that specifies the stackup, material type (e.g., Rogers 4350B), copper weight, impedance requirements, and surface finish.

Resources for RF Generator PCB (related pages and tools)

- Material Data: Rogers PCB Materials

- Design Tools: Impedance Calculator

- Manufacturing Capabilities: High Frequency PCB Manufacturing

- Quality Assurance: Testing and Quality Control

RF Generator PCB glossary (key terms)

| Term | Definition |

|---|---|

| DDS | Direct Digital Synthesis. A method of producing an analog waveform by generating a time-varying signal in digital form and then performing a digital-to-analog conversion. |

| VCO | Voltage Controlled Oscillator. An electronic oscillator whose oscillation frequency is controlled by a voltage input. |

| PLL | Phase-Locked Loop. A control system that generates an output signal whose phase is related to the phase of an input signal. |

| Impedance | The effective resistance of an electric circuit or component to alternating current, arising from the combined effects of ohmic resistance and reactance. |

| Skin Effect | The tendency of a high-frequency alternating current to become distributed within a conductor such that the current density is largest near the surface. |

| Insertion Loss | The loss of signal power resulting from the insertion of a device (or PCB trace) in a transmission line. |

| Return Loss | The loss of power in the signal returned/reflected by a discontinuity in a transmission line. |

| Dk (Dielectric Constant) | A measure of a material's ability to store electrical energy in an electric field. Affects signal speed. |

| Df (Dissipation Factor) | A measure of loss-rate of energy of a mode of oscillation (mechanical, electrical, or electromechanical) in a dissipative system. |

| Tg (Glass Transition Temp) | The temperature at which the PCB base material transitions from a glassy, rigid state to a softened, deformable state. |

| VNA | Vector Network Analyzer. A test instrument used to characterize RF devices. |

| TDR | Time Domain Reflectometry. A measurement technique used to determine the characteristics of electrical lines by observing reflected waveforms. |

Conclusion (next steps)

Designing and manufacturing an RF Generator PCB requires a shift in mindset from standard digital logic to analog physics. Whether you are building a high-speed BER Generator PCB or a precision DDS Generator PCB, the interaction between the dielectric material, copper roughness, and stackup geometry determines the success of your product.

To ensure your design is manufacturable and meets performance goals, early engagement with your fabrication partner is essential. At APTPCB, we recommend performing a DFM (Design for Manufacturing) review before finalizing your layout.

Ready to move forward? When submitting your data for a quote or review, please ensure you provide:

- Gerber Files: RS-274X format.

- Stackup Diagram: Specifying dielectric materials and layer order.

- Impedance Requirements: Clearly marked traces and target values.

- Frequency Range: Operating frequency helps us suggest the most cost-effective material.

Contact our engineering team today to discuss your RF requirements and ensure your signal generation equipment performs exactly as designed.