Definition, scope, and who this guide is for

Rigid flex bend area keepout rules refer to the specific design constraints applied to the flexible sections of a printed circuit board, particularly where the board transitions from a rigid state to a flexible state or undergoes dynamic bending. These rules dictate the minimum distances that vias, components, and copper features must maintain from the bend line and the rigid-to-flex transition zone. Ignoring these constraints is the leading cause of mechanical fractures, conductor work-hardening, and eventual electrical open circuits in the field.

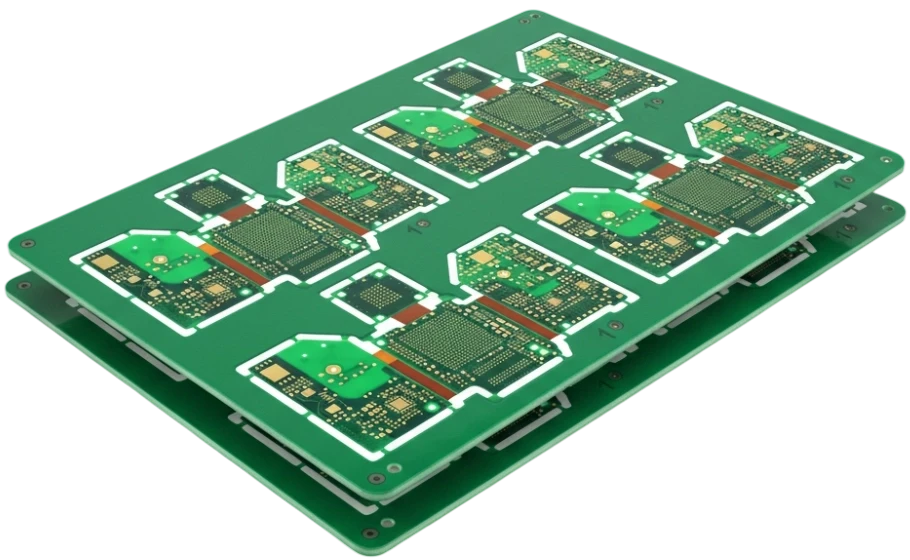

This guide is written for engineering leads, PCB designers, and procurement managers who are responsible for sourcing high-reliability rigid-flex circuits. It moves beyond basic IPC standards to provide a practical framework for specifying, validating, and purchasing boards that survive rigorous installation and operation. You will learn how to define keepout zones to prevent stress concentration, how to validate these designs before mass production, and how to audit a manufacturer like APTPCB (APTPCB PCB Factory) to ensure they can execute your requirements.

The scope covers the mechanical and electrical implications of keepout violations, including impedance discontinuities and coverlay delamination. By following this playbook, you will reduce the risk of costly redesigns and ensure your product meets its lifecycle durability targets.

When to use rigid flex bend area keepout rules (and when a standard approach is better)

Understanding the definition of these rules is only the first step; knowing when to apply strict keepout constraints versus standard design practices is crucial for cost and yield management.

Strict adherence to rigid flex bend area keepout rules is mandatory when:

- Dynamic Flexing Applications: The device acts as a hinge (e.g., laptop screens, folding phones) where the flex circuit undergoes thousands of cycles.

- Tight Bend Radii: The installation requires a bend radius less than 10x the flex thickness, creating immense stress at the transition zone.

- High-Vibration Environments: Aerospace or automotive applications where static bends might oscillate, effectively becoming dynamic stress points.

- Multi-Layer Flex Sections: Designs with 3+ flex layers where the "I-beam" effect increases the stiffness and stress on outer conductors.

- Impedance Controlled Lines: High-speed signals crossing the bend area require specific reference planes that must not be interrupted by keepout violations.

A standard, less aggressive approach may be acceptable when:

- Install-to-Fit (Static): The flex is bent once during assembly and never moves again, provided the bend radius is generous (>15x thickness).

- Single-Sided Flex: The lack of opposing copper layers reduces the risk of compression cracking, allowing slightly tighter proximity to features.

- Low Reliability Consumer Toys: Where field failure consequences are minimal, and cost reduction is the primary driver.

rigid flex bend area keepout rules specifications (materials, stackup, tolerances)

Once you have determined that your application requires strict keepout adherence, you must translate these needs into concrete specifications for your fabrication drawing and CAM instructions.

- Via to Bend Line Distance: Specify a minimum of 1.27mm (50 mils) clearance between the edge of any plated through-hole (PTH) or microvia and the start of the bend area. Vias are rigid structures; placing them in a flex zone causes barrel cracks.

- Component Keepout Zone: Define a strict no-component zone extending 2.0mm to 3.0mm from the rigid-to-flex transition. Solder joints cannot withstand the strain of the transition area.

- Conductor Routing Direction: Mandate that all traces traversing the bend area must run perpendicular (90°) to the bend line. Angled routing causes twisting forces that delaminate the coverlay.

- Trace Width Consistency: Require that trace width remains constant throughout the bend area. Necking down or widening traces creates stress concentration points (stress risers) where cracks initiate.

- Coverlay Openings: Ensure coverlay openings for pads or fingers end at least 1.0mm away from the bend area to prevent the coverlay from peeling under tension.

- Stiffener Termination: Specify that rigid stiffeners must overlap the rigid section by at least 0.75mm to 1.0mm to transfer stress away from the fragile transition line.

- Copper Fill/Hatching: Prohibit solid copper planes in the bend area. Require cross-hatched copper (e.g., 45-degree angle) to retain flexibility and prevent copper work-hardening.

- Solder Mask vs. Coverlay: Explicitly state that flexible polyimide coverlay must be used in the bend area, not standard liquid photoimageable (LPI) solder mask, which is brittle and will crack.

- Transition Zone Filleting: Require teardrops or gradual fillets where traces enter the flex area to distribute mechanical stress, rather than sharp 90-degree corners.

- Layer Count in Flex Area: Limit the flex section to 1 or 2 layers whenever possible. If more are needed, specify unbonded (air gap) construction to allow layers to slide over each other.

- Impedance Continuity: For

rigid flex impedance control and stackup planning, specify that reference planes must remain continuous through the bend area (using cross-hatching) to avoid signal reflection.

rigid flex bend area keepout rules manufacturing risks (root causes and prevention)

Defining specifications is essential, but understanding the specific failure modes associated with rigid flex bend area keepout rules helps you anticipate and mitigate risks during volume production.

- Risk: Conductor Work-Hardening (Cracking)

- Why it happens: Repeated bending causes the copper grain structure to become brittle, eventually snapping like a paperclip.

- Detection: Intermittent electrical failures during dynamic testing.

- Prevention: Use Rolled Annealed (RA) copper instead of Electro-Deposited (ED) copper in the flex stackup.

- Risk: Transition Zone Delamination

- Why it happens: The adhesive interface between the rigid prepreg and the flexible coverlay shears under bending stress.

- Detection: Visible bubbling or separation at the rigid-flex interface after thermal cycling.

- Prevention: Ensure the "bead" of adhesive (squeeze-out) is controlled but sufficient to seal the interface, and keep vias away from this stress line.

- Risk: Plated Through-Hole (PTH) Barrel Cracks

- Why it happens: Vias placed too close to the bend line (violating the keepout) deform into ovals, cracking the copper plating.

- Detection: Open circuits that appear only when the device is bent.

- Prevention: Enforce the 1.27mm via keepout rule strictly in CAM reviews.

- Risk: Solder Joint Fracture

- Why it happens: Components placed inside the keepout zone experience torque, cracking the brittle intermetallic compound.

- Detection: Components falling off or intermittent contact.

- Prevention: Move all SMT parts to the rigid section, at least 2mm from the transition.

- Risk: Coverlay Lifting

- Why it happens: Traces routed at angles in the bend area create twisting forces that peel the coverlay.

- Detection: Visual inspection shows white patches (air gaps) under the coverlay.

- Prevention: Route traces perpendicular to the bend; use "anchor" vias in the rigid section to hold traces in place.

- Risk: Impedance Mismatch

- Why it happens: The change in dielectric material (FR4 to Polyimide) and reference plane structure (solid to hatched) alters characteristic impedance.

- Detection: Signal integrity degradation (eye diagram closure) in high-speed tests.

- Prevention: Perform detailed

rigid flex impedance control and stackup planningsimulation before fabrication.

- Risk: I-Beam Effect Failure

- Why it happens: Stacked traces on top and bottom layers stiffen the flex, causing the outer layers to stretch and crack.

- Detection: Outer layer traces fail first during bend testing.

- Prevention: Stagger traces on adjacent layers so they do not overlap directly (offset routing).

- Risk: Laser Cutting Carbonization

- Why it happens: Poor laser profiling of the flex outline leaves carbon residue, creating leakage paths.

- Detection: Low insulation resistance (IR) test failures.

- Prevention: Specify proper laser settings and post-process plasma cleaning.

rigid flex bend area keepout rules validation and acceptance (tests and pass criteria)

To ensure your design and the manufacturer's process have successfully mitigated the risks above, you must implement a robust validation plan focused on rigid flex transition zone failure modes.

- Objective: Verify Mechanical Durability (Dynamic)

- Method: IPC-TM-650 2.4.3 Flexural Endurance Test. Cycle the board at the intended bend radius.

- Acceptance Criteria: No electrical discontinuity (>10% resistance increase) after 100,000 cycles (or spec requirement).

- Objective: Verify Static Bend Reliability

- Method: Install-to-fit simulation. Bend the flex to the installation angle and hold for 24 hours at elevated temperature (85°C).

- Acceptance Criteria: No visible delamination, cracking, or resistance change.

- Objective: Validate Transition Zone Integrity

- Method: Micro-section analysis (cross-section) of the rigid-flex interface.

- Acceptance Criteria: No voids in the adhesive flow, no cracks in the copper near the transition, and proper coverlay registration.

- Objective: Confirm Impedance Control

- Method: Time Domain Reflectometry (TDR) testing on coupons and actual boards.

- Acceptance Criteria: Impedance values within ±10% (or ±5% for high speed) across the entire path, including the bend area.

- Objective: Check for Work-Hardening

- Method: Elongation test on copper traces after limited cycling.

- Acceptance Criteria: Copper retains ductility; no micro-cracks visible under 100x magnification.

- Objective: Verify Via Reliability near Keepout

- Method: Thermal shock testing (-40°C to +125°C, 500 cycles).

- Acceptance Criteria: No barrel cracks in vias closest to the transition zone; resistance change <5%.

- Objective: Inspect Coverlay Adhesion

- Method: Tape test (IPC-TM-650 2.4.1) over the bend area.

- Acceptance Criteria: No coverlay removal or lifting.

- Objective: Dielectric Withstand

- Method: Hi-Pot testing between layers in the flex area.

- Acceptance Criteria: No breakdown or leakage current exceeding limits, ensuring no carbonization or contamination.

rigid flex bend area keepout rules supplier qualification checklist (RFQ, audit, traceability)

Validating the product is critical, but validating the supplier's capability to adhere to rigid flex bend area keepout rules prevents issues before metal is cut. Use this checklist when engaging with APTPCB or other vendors.

RFQ Inputs (What you must provide)

- Detailed Stackup: Clearly defining rigid layers, flex layers, and adhesive types.

- Bend Radius Specification: The exact radius and angle of the bend in the final assembly.

- Keepout Layer in Gerbers: A specific mechanical layer explicitly marking the "No Via / No Component" zones.

- Material Requirements: Specifying Rolled Annealed (RA) copper and adhesive-less polyimide if required.

- Impedance Models: Target impedance for traces traversing the flex zone.

- Dynamic vs. Static: Clearly stating the lifecycle usage (number of flex cycles).

- Surface Finish: ENIG or ENEPIG is preferred for wire bonding; HASL is generally avoided on flex.

- Dimensional Tolerances: Specifically for the flex outline and stiffener placement.

Capability Proof (What the supplier must demonstrate)

- Minimum Bend Radius Capability: Can they manufacture to your required radius without cracking?

- Registration Accuracy: Can they hold ±50µm registration between rigid and flex layers?

- Laser Cutting Precision: Do they use UV lasers for clean flex outlines without carbonization?

- Plasma Cleaning: Do they have in-house plasma desmear to ensure hole wall adhesion in acrylic/polyimide stacks?

- Impedance Testing: Do they have TDR equipment capable of measuring differential pairs on flex?

- Automated Optical Inspection (AOI): Is AOI performed on inner flex layers before lamination?

Quality System & Traceability

- Cross-Section Reports: Will they provide micro-sections of the transition zone with every shipment?

- Material Certifications: Can they trace the RA copper lot back to the mill?

- IPC Class 3 Capability: Do they have experience manufacturing to IPC-6013 Class 3 standards?

- Failure Analysis: Do they have an in-house lab to analyze flex cracks if they occur?

- DFM Feedback: Do they actively flag keepout violations during the CAM review?

Change Control & Delivery

- Sub-contracting Policy: Do they laminate in-house or outsource the critical rigid-flex pressing?

- Stackup Locking: Will they guarantee no material changes without written approval?

- Packaging: Do they ship panels with support to prevent bending during transit?

- Lead Time: Is the lead time realistic for complex lamination cycles (usually 15-20+ days)?

How to choose rigid flex bend area keepout rules (trade-offs and decision rules)

Engineering is the art of compromise. When finalizing your rigid flex pcb design, you will face conflicting constraints. Here is how to navigate them.

- Reliability vs. Size:

- If you prioritize maximum reliability: Increase the bend radius and extend the keepout zone to 2mm+.

- If you prioritize miniaturization: Use thinner materials (0.5 oz copper, 1/2 mil adhesive) to allow tighter bends, but accept lower mechanical safety margins.

- Flexibility vs. Layer Count:

- If you prioritize flexibility: Keep the flex section to 1 or 2 layers.

- If you prioritize signal density: Use a "bookbinder" or "air gap" construction for 4+ layers, but be prepared for significantly higher manufacturing costs.

- Cost vs. Performance:

- If you prioritize cost: Use standard adhesive-based polyimide and static bending rules.

- If you prioritize high-speed performance: Use adhesive-less materials and cross-hatched planes for impedance control, which increases material cost but ensures signal integrity.

- Durability vs. Assembly Ease:

- If you prioritize durability: Use stiffeners that overlap the rigid section to relieve strain.

- If you prioritize assembly speed: Ensure the stiffeners do not interfere with connector insertion or housing fitment.

- Signal Integrity vs. Mechanical Life:

- If you prioritize signal integrity: You may need solid reference planes.

- If you prioritize mechanical life: You must use cross-hatched planes. Compromise: Use silver ink shields or specialized EMI films that are flexible.

rigid flex bend area keepout rules FAQ (cost, lead time, Design for Manufacturability (DFM) files, stackup, impedance, Automated Optical Inspection (AOI) inspection)

What is the standard keepout distance for vias from the rigid-flex interface? The industry standard is at least 1.27mm (50 mils). For high-reliability Class 3 products, 2.54mm (100 mils) is preferred to isolate the via barrel from stress.

Can I place components on the flexible section of the PCB? Technically yes, but it is highly discouraged for dynamic applications. If necessary, you must use a stiffener directly under the component area to make it locally rigid, effectively creating a "rigid island."

Why must traces be perpendicular to the bend line? Traces running at an angle experience torque (twisting) and shear forces during bending, which promotes delamination and copper cracking. Perpendicular traces only experience tension/compression.

What is the "I-Beam" effect in rigid-flex design? This occurs when traces on the top and bottom layers of a flex circuit are stacked directly on top of each other. This increases the stiffness of the stack (like an I-beam), reducing flexibility and increasing the risk of cracking. Staggering traces prevents this.

How do I handle impedance control in the bend area? You must maintain a reference plane. Since solid copper reduces flexibility, use a cross-hatched ground plane. You will need to adjust the trace width to compensate for the inductance change caused by the hatching.

What is the difference between static and dynamic flex? Static flex (flex-to-install) is bent once during assembly. Dynamic flex is bent repeatedly during use. Dynamic flex requires RA copper, strictly one layer (if possible), and much larger bend radii.

Do I need teardrops on pads in the flex area? Yes. Teardrops provide mechanical reinforcement where the trace meets the pad, reducing the likelihood of the trace snapping off at the junction during thermal or mechanical stress.

Why is coverlay preferred over solder mask for flex circuits? Standard solder mask is brittle and will crack when bent. Polyimide coverlay is a flexible film laminated onto the copper, providing robust insulation that can withstand thousands of flex cycles.

Resources for rigid flex bend area keepout rules (related pages and tools)

- Rigid-Flex PCB Capabilities – Explore the specific layer counts, materials, and tolerances APTPCB can achieve for your project.

- DFM Guidelines – Access detailed design rules to ensure your keepout zones and stackups are manufacturable.

- PCB Stackup Design – Learn how to plan complex rigid-flex structures to balance impedance and mechanical flexibility.

- Flex PCB Technology – Understand the core materials and properties of flexible circuits that underpin rigid-flex designs.

- Impedance Calculator – Verify your trace width and spacing requirements before finalizing your keepout zones.

Request a quote for rigid flex bend area keepout rules (Design for Manufacturability (DFM) review + pricing)

Ready to validate your design? Request a Quote from APTPCB today to get a comprehensive DFM review that specifically checks your rigid flex bend area keepout rules against manufacturing realities.

To get the most accurate DFM and pricing, please include:

- Gerber Files (RS-274X): Including a dedicated outline layer defining rigid and flex zones.

- Fabrication Drawing: Specifying materials (RA vs. ED copper), stackup, and bend radius.

- Netlist: To verify electrical continuity logic.

- Volume Estimates: Prototype quantity vs. mass production targets.

- Special Requirements: Impedance control reports, Class 3 specs, or specific stiffener materials.

Conclusion (next steps)

Mastering rigid flex bend area keepout rules is the difference between a reliable, high-performance product and a field failure nightmare. By strictly enforcing via keepouts, managing transition zone stresses, and validating your design with rigorous testing, you ensure mechanical integrity without sacrificing electrical performance. Use the checklist and specifications in this guide to align your engineering team and hold your suppliers accountable, ensuring a smooth transition from prototype to mass production.