Quick Answer (30 seconds)

Designing a safety wearable ipx7 pcb requires balancing miniaturization with robust environmental protection. IPX7 certification demands the device withstand immersion in water up to 1 meter deep for 30 minutes. For safety-critical wearables, this reliability is non-negotiable.

- Waterproofing Strategy: Relying solely on mechanical enclosure seals is risky. Use Parylene conformal coating or low-pressure molding (potting) on the PCB itself.

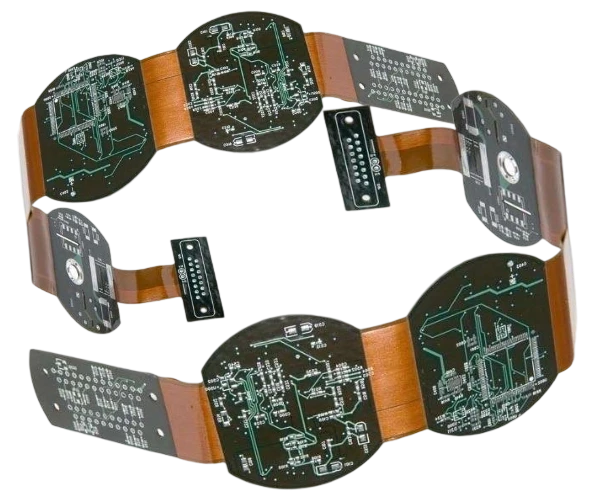

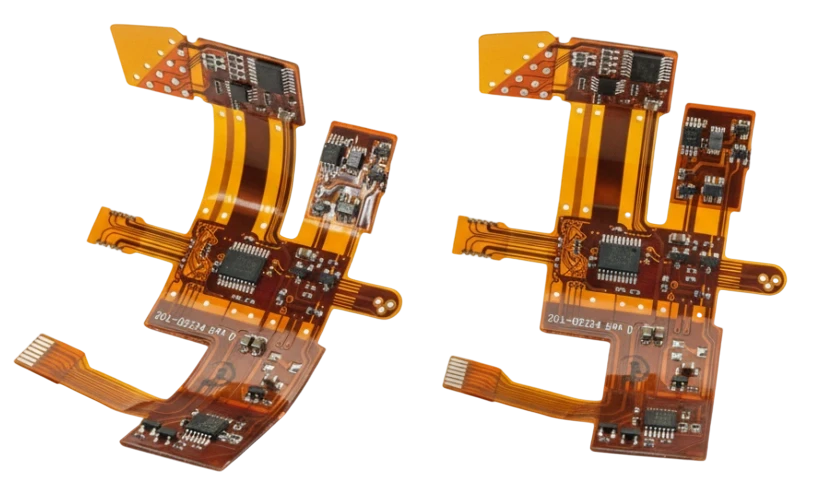

- Board Technology: Rigid-flex PCBs are the standard for wearables to accommodate curved housings and reduce connector failures.

- Component Placement: Keep sensitive ICs (MCUs, PMICs) at least 3mm away from the board edge to allow for potting flow or seal compression.

- Connectivity: Prefer wireless charging or waterproof USB-C connectors with O-ring seals to minimize ingress points.

- Validation: Perform vacuum leak testing on 100% of units before final assembly; do not rely only on batch water immersion tests.

- Safety Standards: For industrial environments, ensure the design meets intrinsic safety wearable pcb standards (like UL 913) to prevent ignition in hazardous zones.

APTPCB (APTPCB PCB Factory) specializes in manufacturing high-reliability boards for these demanding applications. We ensure your design meets strict IPX7 and safety requirements through rigorous DFM checks.

When safety wearable ipx7 pcb applies (and when it doesn’t)

Not every wearable needs IPX7, and some need even more. Understanding the use case prevents over-engineering or catastrophic field failure.

When it applies (Go)

- Elderly Safety Hubs: Devices worn in the shower for fall detection. Moisture resistance is critical for 24/7 protection.

- Industrial Lone Worker Monitors: Devices used in oil rigs or chemical plants where rain, sweat, and accidental drops in puddles occur.

- Smart Swim Bands: Fitness trackers specifically designed for surface swimming and lap tracking.

- Safety Lighting Wearables: High-visibility gear for outdoor construction workers exposed to heavy storms.

- Medical Patient Monitors: Devices that require regular sanitization with liquid disinfectants.

When it doesn’t apply (No-Go)

- Deep Sea Diving Gear: IPX7 is insufficient. These require IPX8 or higher pressure ratings (ATM ratings).

- Office-Only Smart Badges: IP54 (splash proof) is usually enough; IPX7 adds unnecessary cost.

- High-Pressure Cleaning Environments: Food processing wearables often need IP69K to withstand high-pressure steam jets, which IPX7 cannot handle.

- Disposable Smart Patches: If the device life is <24 hours, full IPX7 potting may be cost-prohibitive compared to simple film barriers.

Rules & specifications

The following table outlines the critical engineering rules for a successful safety wearable ipx7 pcb. Ignoring these often leads to field returns due to moisture ingress or thermal failure.

| Rule | Recommended Value/Range | Why it matters | How to verify | If ignored |

|---|---|---|---|---|

| Water Ingress Rating | IPX7 (1m, 30 min) | Prevents short circuits during submersion. | IEC 60529 Immersion Test. | Device dies after dropping in water. |

| Conformal Coating | Parylene C (25-50µm) | Provides a pinhole-free barrier against moisture even if the case leaks. | UV trace inspection / Thickness gauge. | Dendritic growth and corrosion. |

| PCB Type | Rigid-Flex PCB | Eliminates fragile connectors; fits curved ergonomic cases. | 3D CAD Fit Check / Bend Radius calc. | Intermittent connections; bulky housing. |

| Trace Spacing (HV) | >0.2mm (low voltage) | Prevents electrochemical migration under humidity. | IPC-2221 Voltage Clearance check. | Short circuits via dendrites. |

| Thermal Dissipation | <40°C Case Temp | Sealed IPX7 cases trap heat; skin burns are a safety risk. | Thermal simulation / IR Camera. | Battery swelling; user injury. |

| Battery Protection | Dual redundant ICs | Prevents thermal runaway in sealed enclosures. | Fault injection testing. | Fire hazard; explosion. |

| Antenna Tuning | Tuned with potting | Potting compounds change dielectric constant ($D_k$), detuning RF. | VNA measurement after potting. | Poor range; lte nb iot safety wearable pcb fails to connect. |

| Seal Width | >1.5mm land | Ensures O-ring or adhesive has sufficient contact area. | Mechanical CAD review. | Water leaks through the seam. |

| Test Points | Covered / Wireless | Exposed test points are corrosion vectors. | Visual inspection. | Corrosion enters internal layers. |

| Flex Bend Radius | >10x thickness | Prevents copper cracking during dynamic movement. | IPC-2223 Design Check. | Open circuits after minimal use. |

| Material Tg | >150°C (High Tg) | Withstands potting cure temps and operating heat. | Datasheet verification. | PCB delamination during assembly. |

| Intrinsic Safety | UL 913 / IECEx | Required for safety wearable ul 913 pcb in explosive zones. | Certification audit. | Legal liability; explosion risk. |

Implementation steps

Follow this process to move from concept to a mass-producible safety wearable ipx7 pcb.

Define Environmental Profile

- Action: Determine if the device faces salt water, chlorinated water, or chemicals.

- Parameter: Chemical resistance of the housing and coating.

- Check: Verify material compatibility (e.g., Polycarbonate vs. Acetone).

Select PCB Stackup & Materials

- Action: Choose a Rigid-Flex structure to maximize space. Use High-Tg FR4.

- Parameter: 4-layer Rigid, 2-layer Flex is common for wearables.

- Check: Confirm impedance control for Bluetooth/LTE antennas.

Layout for Waterproofing

- Action: Keep components 3mm away from board edges. Group connectors for localized sealing.

- Parameter: Keep-out zones for O-rings or glue dispensing.

- Check: 3D interference check in CAD.

Thermal Management Design

- Action: Use copper pours and thermal vias to spread heat to the battery or backplate.

- Parameter: Max component junction temperature.

- Check: Simulate heat saturation in a fully sealed (airtight) environment.

Prototype Assembly & Coating

- Action: Assemble SMT components, then apply Conformal Coating.

- Parameter: Coating thickness and masking of connectors.

- Check: UV light inspection to ensure full coverage without contaminating contact pads.

Integration & Sealing

- Action: Install PCB into the housing. Apply ultrasonic welding or adhesive sealing.

- Parameter: Bond line thickness and cure time.

- Check: Visual inspection of the seal line.

Leak Testing (Dry)

- Action: Perform air vacuum decay testing.

- Parameter: Pressure drop <X Pa over Y seconds.

- Check: Pass/Fail indication before any water touches the unit.

Functional & RF Testing

- Action: Test lte nb iot safety wearable pcb connectivity inside the final housing.

- Parameter: RSSI levels and packet loss.

- Check: Verify antenna performance hasn't shifted due to the enclosure.

Failure modes & troubleshooting

Even with good design, failures happen. Here is how to diagnose issues with safety wearable ipx7 pcb units.

1. Moisture Corrosion (Green/White Residue)

- Symptom: Device stops working after shower/swim; visible residue on PCB.

- Causes: Seal failure, coating pinholes, or connector ingress.

- Checks: Dye penetration test (red dye in water) to find the leak path.

- Fix: Improve O-ring compression or switch to Parylene coating.

- Prevention: Implement 100% air leak testing on the production line.

2. Battery Swelling / Overheating

- Symptom: Case deforms; device shuts down randomly.

- Causes: Poor thermal dissipation in sealed IPX7 case; charging circuit fault.

- Checks: Thermal profiling during charging cycles.

- Fix: Reduce charging current; add graphite heat spreaders.

- Prevention: Design thermal vias to conduct heat to the metal buckle or case back.

3. Intermittent Sensor Data

- Symptom: Heart rate or fall detection works sporadically.

- Causes: Flex cable cracking (dynamic stress) or connector fretting.

- Checks: Micro-sectioning of the flex circuit.

- Fix: Increase bend radius; use "tear drops" on flex pads.

- Prevention: Use Rigid-Flex PCB to eliminate board-to-board connectors.

4. RF Connectivity Loss

- Symptom: elderly safety hub pcb loses connection indoors.

- Causes: Antenna detuning caused by potting compound or water proximity.

- Checks: VNA measurement of antenna matching in the finished assembly.

- Fix: Retune antenna matching network for the potted dielectric constant.

- Prevention: Simulate antenna performance with the housing and potting material properties.

5. False Touch / Ghost Touch

- Symptom: Screen reacts to water droplets.

- Causes: Capacitive touch controller too sensitive to water.

- Checks: Water spray test.

- Fix: Adjust firmware sensitivity; use self-capacitance vs mutual-capacitance tuning.

- Prevention: Implement "water lock" software mode.

6. Audio Distortion

- Symptom: Muffled sound from speaker/mic.

- Causes: Waterproof membrane (Gore-tex) clogged or glued improperly.

- Checks: Acoustic frequency response test.

- Fix: Change adhesive process for the acoustic mesh.

- Prevention: Ensure acoustic mesh is oleophobic (repels oils/sweat).

Design decisions

Potting vs. Conformal Coating

For safety wearable ipx7 pcb, the choice between potting and coating is critical.

- Conformal Coating (Spray/Dip): Thin, lightweight. Good for IPX7 if the case seal is primary. Parylene is best but expensive.

- Potting (Encapsulation): Fills the entire void. Provides IP68+ protection and shock resistance but adds weight and makes rework impossible.

- Decision: Use Parylene for lightweight consumer wearables. Use Potting for heavy-duty intrinsic safety wearable pcb industrial gear.

Charging: Pogo Pins vs. Wireless vs. USB-C

- USB-C: Hard to waterproof reliably over time. Requires expensive waterproof connectors.

- Pogo Pins: Exposed gold pads can corrode (galvanic corrosion) due to sweat and voltage.

- Wireless (Qi): Best for IPX7. No holes in the case.

- Decision: Wireless is preferred for high-end safety wearables. If using Pogo pins, use corrosion-resistant plating (Hard Gold >30µin) and remove voltage when not charging.

Rigid vs. Rigid-Flex

- Rigid PCB: Cheaper. Requires wires/connectors to fit curved cases. Connectors are failure points.

- Rigid-Flex: More expensive upfront. Fits complex shapes perfectly. High reliability.

- Decision: APTPCB recommends Rigid-Flex for any wearable where reliability is a safety concern (e.g., fall detection).

FAQ

Q: What is the difference between IP67 and IPX7? A: IP67 includes a dust rating (6 = dust tight). IPX7 only specifies water protection (X = not tested for dust). For wearables, IP67 is usually implied since a water-tight seal is also dust-tight.

Q: Can I use standard FR4 for safety wearables? A: Yes, but High-Tg FR4 is recommended if you are potting the board, as the curing heat and operating thermals in a sealed case can stress standard FR4.

Q: How do I ensure my wearable meets UL 913 standards? A: You must limit energy storage (capacitance/inductance) and thermal output. The PCB layout must maintain strict spacing distances. Consult our Medical PCB and safety experts early.

Q: Is potting necessary for IPX7? A: Not always. A high-quality mechanical seal (O-ring/ultrasonic weld) plus conformal coating is often sufficient. Potting is used when mechanical shock or extreme durability is needed.

Q: How does water affect Bluetooth/LTE signals? A: Water absorbs 2.4GHz signals. An lte nb iot safety wearable pcb or Bluetooth device will lose range if submerged. The antenna design must account for the detuning effect of the human body and water.

Q: What is the best surface finish for wearable PCBs? A: ENIG (Electroless Nickel Immersion Gold) is the standard. It offers excellent flatness for fine-pitch components and high corrosion resistance compared to HASL.

Q: How do I test for IPX7 in mass production? A: Do not submerge every unit. Use air leak testers (vacuum decay). It is faster, non-destructive, and keeps the electronics dry.

Q: Why is my battery swelling in the IPX7 case? A: Sealed cases trap heat. If the charging circuit generates heat that cannot escape, the battery degrades. Improve thermal paths to the case surface.

Q: Can APTPCB help with the enclosure design? A: We focus on the PCB and PCBA. However, our DFM Guidelines provide critical feedback on how the PCB fits into the enclosure to ensure successful sealing.

Q: What is the lead time for a rigid-flex safety wearable PCB? A: Prototypes typically take 8-12 days due to the complex lamination process. Standard rigid boards are faster (3-5 days).

Glossary (key terms)

| Term | Definition |

|---|---|

| IPX7 | Ingress Protection rating: Protected against immersion in water up to 1 meter for 30 minutes. |

| Rigid-Flex | A hybrid PCB technology combining rigid board areas with flexible circuits, eliminating connectors. |

| Conformal Coating | A protective chemical film (Acrylic, Silicone, Urethane, Parylene) applied to the PCBA. |

| Potting | Encapsulating the electronics in a resin (epoxy/silicone) for maximum protection. |

| Intrinsic Safety | A design technique (e.g., UL 913) limiting energy to prevent explosions in hazardous areas. |

| NB-IoT | Narrowband IoT. A low-power cellular standard used in lte nb iot safety wearable pcb devices. |

| Galvanic Corrosion | Electrochemical damage occurring when two dissimilar metals are in electrical contact in an electrolyte (sweat). |

| Underfill | Epoxy applied under BGA/CSP components to improve mechanical shock resistance. |

| Leakage Current | Unintended current flow across the PCB surface due to moisture or contamination. |

| O-Ring | A mechanical gasket in the shape of a torus used to create a seal at the interface. |

| HDI | High Density Interconnect. PCB technology using microvias to fit more tech in small spaces. |

| DFM | Design for Manufacturing. The process of optimizing a design for efficient production. |

Request a quote

Ready to manufacture your safety wearable ipx7 pcb? APTPCB provides comprehensive DFM reviews to catch waterproofing and layout issues before production begins.

To get an accurate quote and DFM report, please provide:

- Gerber Files: RS-274X format preferred.

- Stackup: Specify Rigid-Flex layers if applicable.

- BOM: For turnkey assembly (include specific coating requirements).

- Drawings: Note critical dimensions, coating zones, and test points.

- Volume: Prototype quantity vs. mass production targets.

Request a Quote – Our engineers will review your files and suggest optimizations for IPX7 reliability and cost.

Conclusion

Developing a safety wearable ipx7 pcb is about more than just a watertight case; it requires a holistic approach to PCB materials, layout, and protective coatings. Whether you are building an intrinsic safety wearable pcb for hazardous zones or an elderly safety hub pcb for home care, the reliability of the electronics is paramount. By following strict design rules—such as using Rigid-Flex technology, applying proper conformal coating, and validating with air leak testing—you ensure your device protects the user in any environment. Trust APTPCB to deliver the manufacturing precision these life-critical devices demand.