Contents

- The Context: What Makes Server System Board Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Server System Board (What to Send)

- Conclusion

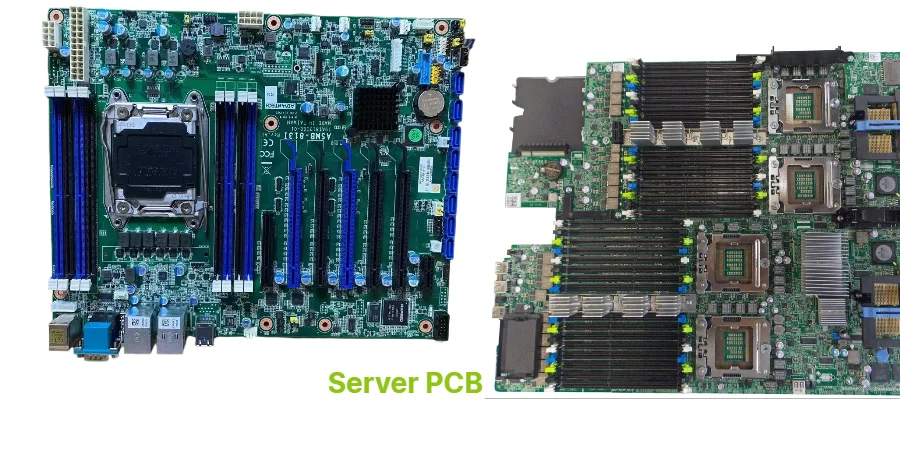

For engineers and procurement teams at APTPCB (APTPCB PCB Factory), a "good" server board is defined by three non-negotiable metrics: signal integrity at high frequencies (PCIe Gen 5/6), thermal stability under heavy computational loads, and absolute manufacturing reliability. This article explores the technical narrative behind these complex boards, detailing the design choices that separate a standard PCB from a high-performance server solution.

Highlights

- Signal Integrity is Paramount: How material selection and backdrilling prevent signal loss in high-speed data lanes.

- Thermal Management: The role of heavy copper and airflow-optimized layouts in cooling high-TDP CPUs.

- Layer Stackup Complexity: Why server boards often require 12 to 24+ layers with mixed dielectrics.

- Manufacturing Precision: The necessity of tight impedance control and advanced registration techniques.

- Future-Proofing: Preparing designs for AI workloads and next-generation interconnects.

The Context: What Makes Server System Board Challenging

Designing and manufacturing a Server System Board is a balancing act between physical space constraints and electrical performance requirements. Unlike consumer electronics where miniaturization is the primary goal, server boards face the challenge of density within fixed form factors—typically 1U, 2U, or 4U chassis standards.

The primary challenge lies in the sheer volume of connections. A modern dual-socket server board must route thousands of signals between CPUs, DDR5 memory slots, and PCIe expansion cards. This routing density forces the use of high layer counts, often exceeding 16 or 20 layers. As layer counts rise, the aspect ratio for plating through-holes becomes more difficult to manage, requiring advanced plating capabilities to ensure barrel reliability.

Furthermore, the transition to higher data rates means that standard FR4 materials are often insufficient. At speeds exceeding 25 Gbps per lane, dielectric loss becomes a signal killer. Engineers must integrate Server and Data Center PCB solutions that utilize low-loss laminates, which are harder to process and more expensive than traditional materials. The challenge is to achieve the necessary electrical performance without making the board unmanufacturable or cost-prohibitive.

The Core Technologies (What Actually Makes It Work)

To meet the rigorous demands of modern data centers, several advanced manufacturing technologies are employed. These are not optional "add-ons" but fundamental requirements for functionality.

Low-Loss Laminates: Standard epoxy glass cannot support the signal speeds of modern servers. Manufacturers utilize advanced materials like Megtron PCB series (Megtron 6 or 7) or equivalent Isola grades. These materials have a lower Dissipation Factor (Df) and Dielectric Constant (Dk), preserving signal integrity over long trace lengths.

Backdrilling (Controlled Depth Drilling): In high-speed designs, the unused portion of a plated through-hole (the "stub") acts as an antenna, causing signal reflections. Backdrilling removes this stub by drilling out the copper plating from the unused side, significantly reducing signal distortion. This process requires extreme precision to avoid damaging the active internal layers.

High Density Interconnect (HDI): To fit the massive pin counts of modern server CPUs (often BGAs with thousands of balls), HDI PCB technology is frequently used. This involves laser-drilled microvias, blind vias, and buried vias to route signals from the inner layers to the surface without consuming valuable board real estate.

Heavy Copper and Power Planes: Servers consume significant power. To deliver hundreds of amps to the processors with minimal voltage drop, internal power planes often use 2oz or 3oz copper. This heavy copper also aids in spreading heat laterally across the board, acting as a built-in heat sink.

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

A Server System Board does not operate in a vacuum. It is the central hub of a larger hardware ecosystem. Understanding these relationships is crucial for successful system integration.

The Backplane Connection: In many rack-mount servers, the system board connects to a Backplane PCB. The backplane handles the hot-swappable storage drives. The interface between the system board and the backplane must be robust, often utilizing high-speed connectors that require precise mechanical alignment during assembly. If the system board warps during reflow, this alignment can fail.

Assembly and Testing (PCBA): The assembly process for server boards is distinct due to the component size and board thermal mass. Large BGA sockets and heavy copper planes require carefully profiled reflow ovens to ensure solder joints form correctly without overheating sensitive components. PCBA providers must use X-ray inspection (AXI) to verify the quality of solder joints under large processors and memory slots, as visual inspection is impossible.

Riser Cards and Expansion: To fit vertically in a 1U or 2U chassis, PCIe slots are often relocated to riser cards. The system board must route high-speed signals to the edge connectors for these risers, introducing another transition point where impedance control is critical.

Comparison: Common Options and What You Gain / Lose

When specifying a Server System Board, engineers face trade-offs between cost, performance, and manufacturability. The choice of materials and surface finishes can drastically alter the board's capabilities and longevity.

Below is a decision matrix to help visualize the impact of these technical choices.

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| Material: Mid-Loss vs. Ultra-Low Loss | Mid-loss saves cost but limits trace length for PCIe Gen5. Ultra-low loss enables longer reach but increases raw material cost by 30-50%. |

| Surface Finish: ENIG vs. OSP | ENIG offers excellent flatness and shelf life but risks "black pad." OSP is cheaper and good for BGA, but has a shorter shelf life and is sensitive to handling. |

| Via Structure: Through-Hole vs. HDI | Through-hole is simpler to fab but limits routing density. HDI enables finer pitch BGAs and better signal integrity but adds lamination cycles. |

| Copper Weight: 1oz vs. 2oz+ | Heavier copper improves power delivery and thermal spreading but requires wider spacing (etch factor) and makes impedance control harder. |

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

Reliability in server environments is not about if a failure occurs, but when. APTPCB focuses on extending that timeline through rigorous design and process controls.

Signal Integrity (SI): For High Speed PCB designs, impedance control is the baseline. We typically see requirements for ±5% tolerance on differential pairs. Beyond impedance, insertion loss and return loss must be minimized. This is achieved through the use of spread glass weaves to prevent the "fiber weave effect," where signals traveling over glass bundles move slower than those over resin gaps, causing skew.

Power Integrity (PI): Servers experience rapid current transients. If the Power Distribution Network (PDN) impedance is too high, voltage rails will droop, causing logic errors. Low-inductance plane pairs and strategic decoupling capacitor placement are essential. The manufacturing stackup must ensure the dielectric thickness between power and ground planes is minimized to increase interplane capacitance.

Thermal Reliability: Server boards undergo constant thermal cycling. The coefficient of thermal expansion (CTE) mismatch between the copper, resin, and components can lead to barrel cracks in vias or solder joint fatigue. Using high-Tg (Glass Transition Temperature) materials ensures the board remains mechanically stable at operating temperatures.

Process Control: Automated Optical Inspection (AOI) is used after every inner layer etching process. For server boards with 20+ layers, a single open or short on an inner layer scraps the entire expensive board. Registration accuracy—aligning all 20 layers perfectly—is achieved using X-ray drilling for tooling holes and laser direct imaging (LDI).

The Future: Where This Is Going (Materials, Integration, Ai/automation)

The trajectory of server hardware is driven by the insatiable demand for AI and cloud computing. As we move toward PCIe Gen 6 and beyond, the margin for error vanishes.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Data Rates (PCIe) | 32 GT/s (Gen 5) | 128 GT/s (Gen 7) | AI training models require massive bandwidth; PCB copper roughness becomes a limiting factor. |

| Layer Count | 12 - 20 Layers | 24 - 40+ Layers | Routing density increases as chips get smaller but pin counts grow; requires thinner dielectrics. |

| Thermal Dissipation | Air Cooling Focus | Liquid/Immersion Ready | Chip TDPs are skyrocketing; boards must be compatible with immersion cooling fluids. |

Request a Quote / DFM Review for Server System Board (What to Send)

When requesting a quote or a DFM Guidelines review for a server system board, clarity is key. Because these boards are complex, standard prototype parameters often do not apply. Please provide the following details to ensure an accurate assessment:

- Gerber Files: RS-274X or ODB++ format (preferred for complex data).

- Stackup Diagram: Explicitly state layer count, copper weights, and dielectric thicknesses.

- Material Requirements: Specify the exact laminate (e.g., "Panasonic Megtron 6" or "Isola Tachyon") or acceptable equivalents.

- Impedance Control: A list of target impedances (single-ended and differential) and the layers they apply to.

- Drill Chart: Clearly distinguish between plated through-holes, non-plated holes, and backdrilled holes.

- Via Types: Indicate if blind, buried, or microvias are used (HDI requirements).

- Surface Finish: E.g., ENIG, Immersion Silver, or Hard Gold for edge connectors.

- Quantities & Lead Time: Prototype vs. Mass Production expectations.

Conclusion

The Server System Board is the unsung hero of the digital age, a complex amalgamation of advanced materials, precise engineering, and rigorous manufacturing standards. It requires a holistic approach where signal integrity, power delivery, and thermal management are considered simultaneously.

For engineers looking to deploy reliable infrastructure, partnering with a manufacturer who understands these nuances is critical. APTPCB combines deep industry knowledge with advanced fabrication capabilities to deliver server boards that meet the demands of today’s data centers and tomorrow’s AI workloads. Whether you are in the prototyping phase or scaling for mass deployment, we are ready to support your technical vision.