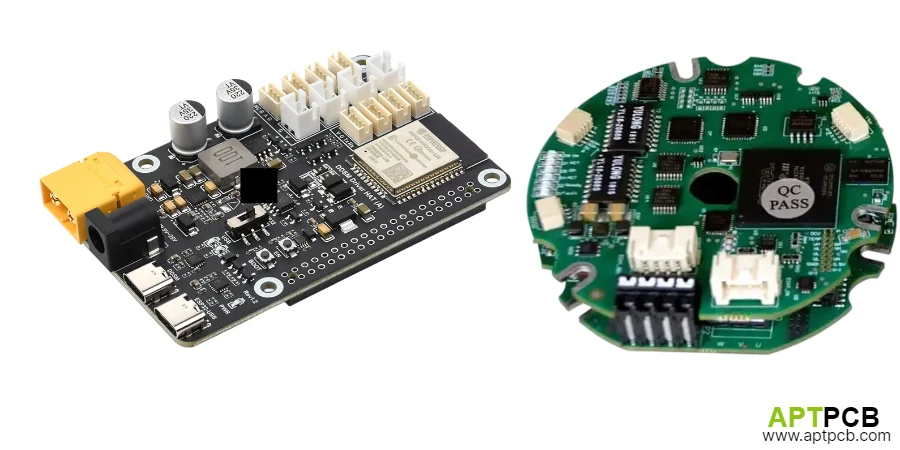

Servo driver PCB assemblies require exceptional precision, thermal management, and reliability to deliver the microsecond-level response times and torque accuracy demanded by industrial automation, robotics, and CNC machinery. Unlike standard motor controllers, servo drivers must integrate high-resolution encoders, advanced control algorithms, and power electronics capable of rapid current switching while maintaining position accuracy within arc-seconds across millions of operational cycles.

At APTPCB, we deliver specialized servo driver PCB assembly services combining precision SMT placement, thermal engineering, and comprehensive functional testing. Our manufacturing capabilities support high-current power stages, digital control integration, and quality validation ensuring servo assemblies perform reliably in demanding industrial environments.

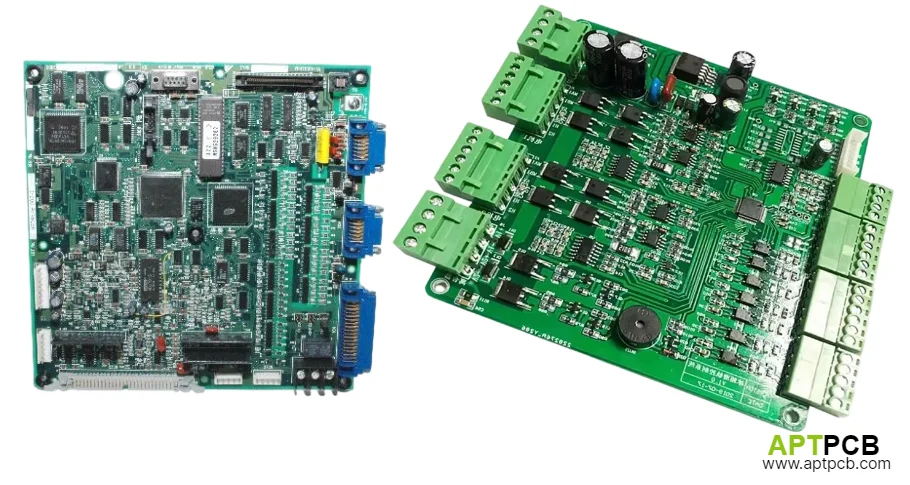

Managing High-Power Requirements in Servo Driver PCB Assembly

Servo driver power stages handle continuous currents from 5A to 50A with peak transients exceeding 100A during acceleration, requiring robust PCB designs and assembly processes that prevent thermal failures or electrical degradation. Poor power management leads to voltage droop, control instability, or premature component failure disrupting production equipment.

At APTPCB, our power electronics assembly expertise implements multi-layer copper distribution, advanced thermal interfaces, and validated soldering processes ensuring reliable high-current operation.

Key High-Power Assembly Techniques

- Heavy Copper PCB Integration: Utilizing heavy copper PCB technology with 3-6oz copper layers distributing high currents without excessive resistance or heating, supporting power MOSFETs and bus bar connections.

- Thermal Interface Application: Precision thermal pad placement and controlled compression ensuring optimal heat transfer from power semiconductors to heat sinks, validated through thermal imaging.

- Power Stage Component Sourcing: Procuring automotive-grade MOSFETs, IGBTs, and gate drivers from authorized distributors with verification preventing counterfeits.

- Bus Capacitor Assembly: Strategic placement and low-inductance mounting of bulk capacitors minimizing ESR and parasitic inductance for stable DC bus voltage during rapid load changes.

- High-Current Connector Integration: Soldering high-amperage connectors with controlled thermal profiles preventing cold joints while avoiding PCB warpage or delamination.

- Power Distribution Validation: Electrical testing verifying voltage drop, current capacity, and thermal performance before functional validation ensures power integrity.

Reliable Performance Under Industrial Loads

By combining multilayer PCB construction, precision assembly processes, and comprehensive testing, APTPCB enables servo driver manufacturers to deliver industrial-grade motion control solutions. Every assembly undergoes power cycling and thermal validation ensuring consistent performance across production batches and operational lifetimes exceeding 50,000 hours in continuous industrial service.

Implementing Precision Control Circuitry in Servo Assemblies

Servo driver control sections integrate high-resolution ADCs, DSP processors, and encoder interfaces requiring precision SMT assembly and signal integrity management. Component placement accuracy within ±25μm and controlled reflow profiles prevent misalignment affecting high-speed digital communication or analog sensing critical for closed-loop position control.

Our assembly processes ensure control circuitry achieves the noise immunity and timing precision necessary for sub-millisecond servo response.

Key Precision Assembly Requirements

- Fine-Pitch IC Placement: Automated pick-and-place handling 0.4mm BGA, QFN packages, and fine-pitch microcontrollers with BGA QFN assembly expertise ensuring reliable electrical connections.

- Encoder Interface Quality: Precision soldering of differential line drivers, receivers, and termination networks maintaining signal integrity for 10MHz+ encoder feedback critical to position accuracy.

- Analog Signal Isolation: Strategic component placement separating analog current sensing from digital switching noise, with ground plane segmentation preventing interference.

- Oscillator and Clock Assembly: Controlled soldering of crystal oscillators and clock circuits maintaining frequency stability within ±50ppm across temperature for timing-critical control loops.

- Communication Interface Integration: RS-485, CANopen, and EtherCAT transceivers assembled with impedance-controlled routing supporting industrial fieldbus communication.

- Firmware Programming: Control firmware and calibration parameters loaded during assembly enabling immediate functional validation.

Consistent Control Performance and Accuracy

Through precision assembly processes and signal integrity validation, APTPCB delivers servo control circuitry achieving position accuracy better than 0.01° and velocity regulation within 0.1% across temperature ranges from -20°C to +70°C. Our quality system ensures every assembly meets stringent industrial performance requirements.

Ensuring Thermal Management in Compact Servo Drivers

Modern servo drivers demand high power density within compact enclosures, creating thermal challenges where inadequate heat dissipation causes derating, thermal shutdown, or reduced lifetime. Effective thermal management requires coordinated PCB design, assembly processes, and validation ensuring reliable operation at maximum rated power.

APTPCB implements comprehensive thermal strategies from material selection through validation testing maintaining junction temperatures within specifications.

Key Thermal Management Techniques

- Metal Core PCB Options: Selective use of metal core PCB or aluminum-backed substrates for power stages improving thermal conductivity and reducing hot spot temperatures.

- Thermal Via Array Assembly: Precision drilling and plating of thermal via arrays beneath power components transferring heat to internal planes or opposite-side heat sinks.

- Heat Sink Attachment: Controlled torque application and thermal interface material verification ensuring proper mechanical and thermal coupling between PCB and external cooling.

- Component Thermal Spacing: Strategic placement maintaining adequate clearance between heat-generating devices preventing thermal coupling and enabling air circulation.

- Conformal Coating Application: Protective coating application protecting assemblies from dust and moisture without compromising thermal dissipation in industrial environments.

- Thermal Validation Testing: Infrared thermal imaging and embedded sensor monitoring verifying temperature distribution and identifying thermal issues before production release.

Industrial-Grade Thermal Reliability

By integrating thermal design principles with advanced PCB manufacturing processes and validation testing, APTPCB delivers servo driver assemblies operating reliably at full power in ambient temperatures up to 50°C. Our thermal management expertise enables compact servo solutions maintaining performance without oversized cooling systems, supporting modern automation equipment design.

Executing Comprehensive Functional Testing for Servo Drivers

Servo driver validation requires testing beyond standard PCB assembly verification—functional testing must verify motion control performance, protection circuits, and communication interfaces under realistic load conditions. Comprehensive testing catches design or assembly issues before field deployment preventing costly equipment failures or production disruptions.

APTPCB provides dedicated servo driver test capabilities validating electrical, thermal, and functional performance specifications.

Key Functional Testing Elements

- Power Stage Testing: Verifying current regulation, switching frequency, and dead-time generation under actual motor loads ensuring proper power delivery and protection.

- Encoder Interface Validation: Testing high-speed encoder feedback circuits with simulated encoder signals verifying position accuracy and communication integrity.

- Control Loop Verification: Validating PID parameters, velocity control, and position accuracy through automated test sequences measuring servo response characteristics.

- Protection Circuit Testing: Triggering overcurrent, overvoltage, and thermal conditions verifying shutdown circuits activate properly preventing component damage.

- Communication Testing: Verifying RS-485, CANopen, or EtherCAT communication under various network conditions ensuring reliable industrial fieldbus operation.

- Burn-In and Reliability Screening: Extended operation at rated power and elevated temperature identifying early failures and validating long-term reliability.

Validated Performance and Quality

Through comprehensive turnkey assembly services including functional validation, APTPCB delivers servo drivers meeting stringent industrial specifications. Our testing processes ensure every assembly achieves specified position accuracy, thermal performance, and communication reliability supporting critical automation applications.

Supporting Industrial Certifications and Compliance

Servo drivers for industrial automation require compliance with safety standards (UL, CE), EMC regulations, and industry-specific certifications (CE machinery directive) enabling equipment sales globally. Assembly processes and documentation must support certification testing and maintain production consistency across batches.

APTPCB provides assembly services supporting regulatory compliance requirements from component traceability through test documentation.

Key Compliance Support Elements

- Material Traceability: Complete component lot tracking and documentation supporting failure investigation and regulatory audits.

- RoHS and REACH Compliance: Material declarations and process controls ensuring assemblies meet environmental regulations for European and global markets.

- UL Recognition Support: Assembly processes following UL requirements with documentation supporting safety certification testing for industrial equipment.

- EMC Assembly Practices: Implementing grounding, shielding, and filtering strategies during assembly supporting conducted and radiated emission compliance.

- First Article Inspection: Documentation with dimensional verification, electrical testing, and functional validation supporting PPAP or customer qualification.

- Production Test Documentation: Comprehensive test records and certificates of conformance supporting customer quality systems and regulatory requirements.

Certified Production Capability

By combining certified manufacturing processes with comprehensive documentation and quality procedures, APTPCB enables servo driver manufacturers achieving regulatory compliance and customer approvals efficiently. Our experience with industrial control applications supports equipment certifications globally.

Delivering Flexible Production for Servo Driver Programs

Servo driver production spans low-volume specialized systems through high-volume standardized products requiring manufacturing flexibility accommodating uncertain demand, product variants, and rapid design changes. Flexible assembly capabilities support product development, market introduction, and volume scaling without quality compromises.

APTPCB provides scalable production from prototypes through volume manufacturing with responsive engineering support.

Key Production Flexibility Capabilities

- Rapid Prototyping: NPI assembly services delivering prototype quantities in 7-10 days supporting design validation and customer sampling.

- Scalable Volume Production: Mass production capabilities accommodating volumes from 100 to 100,000+ units annually with consistent quality and competitive pricing.

- Engineering Change Management: Accommodating design revisions and component substitutions without excessive delays supporting continuous product improvement.

- Multi-Variant Support: Managing product configurations, regional variants, or customer customizations through flexible assembly processes and inventory management.

- Supply Chain Responsiveness: Component procurement strategies with authorized distributor relationships and inventory buffers supporting delivery commitments.

- Technical Support: Engineering assistance with DFM optimization, test development, and troubleshooting supporting successful product launches and production ramps.

Reliable Manufacturing Partnership

Through flexible production capabilities and responsive engineering, APTPCB enables servo driver manufacturers focusing on motion control technology while we deliver reliable, tested assemblies from concept through volume production. Our expertise in industrial electronics supports successful servo driver programs across robotics, CNC, and automation applications.