Solar charge controller assemblies manage energy flow between solar panels and battery banks, protecting batteries from overcharging, over-discharging, and ensuring optimal charging profiles across diverse battery chemistries and system configurations. These controllers serve as the critical interface in off-grid systems, RV installations, marine applications, and backup power solutions requiring reliable battery management for 10-15 year operational lifetimes.

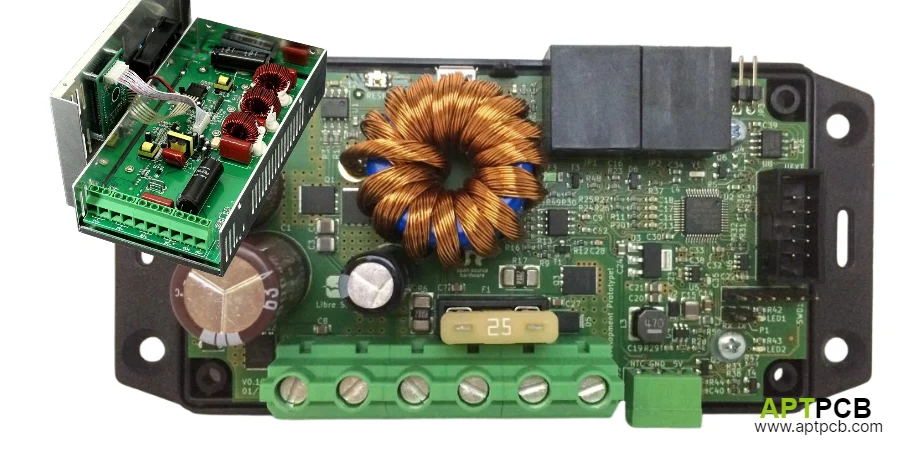

At APTPCB, we deliver comprehensive solar charge controller assembly services combining precision manufacturing, environmental protection, and validated testing. Our capabilities support PWM controllers, MPPT systems, and hybrid solutions across power ranges from 10A to 100A+ serving residential through commercial installations.

Implementing Robust Battery Management Circuits

Charge controller assemblies integrate voltage regulation, current limiting, and temperature compensation preventing battery damage while maximizing charge acceptance and lifetime. Improper charging causes sulfation, capacity loss, or thermal runaway compromising battery performance and safety.

At APTPCB, our assembly expertise implements reliable battery management protecting investments and ensuring system reliability.

Key Battery Management Features

- Multi-Stage Charging: Turnkey assembly implementing bulk, absorption, float, and equalization stages optimizing charge acceptance across battery types.

- Voltage Regulation Accuracy: Precision reference circuits and feedback networks maintaining charge voltage within ±1% preventing overcharge or undercharge conditions.

- Current Control Implementation: Programmable current limiting protecting batteries during bulk charging while preventing controller overcurrent damage.

- Temperature Compensation: Battery temperature sensing enabling automatic voltage adjustment compensating for temperature effects on charging requirements.

- Battery Type Selection: Support for flooded, AGM, gel, lithium-ion, and LiFePO4 batteries through configurable voltage setpoints and charging algorithms.

- Reverse Polarity Protection: Diode and MOSFET protection preventing damage from incorrect battery or panel connections during installation.

Optimized Battery Health

Through comprehensive battery management and testing quality processes, APTPCB delivers charge controller assemblies maximizing battery lifetime and performance across diverse applications.

Executing Load Management and Protection Functions

Charge controllers provide integrated load switching with low-voltage disconnect (LVD) protecting batteries from over-discharge while maintaining power to critical loads. Proper load management prevents battery damage extending service life and maintaining system reliability.

APTPCB implements comprehensive load control with protection circuits.

Key Load Management Capabilities

- Load Switching Integration: High-reliability MOSFET switching handling continuous load currents with minimal voltage drop and power dissipation.

- Low-Voltage Disconnect: Programmable LVD thresholds disconnecting loads before battery damage with hysteresis preventing oscillation.

- Load Reconnect Logic: Automatic load reconnection when battery voltage recovers ensuring system availability without manual intervention.

- Timer Functions: Optional timer-based load control supporting lighting applications and scheduled equipment operation.

- Load Current Monitoring: Current sensing enabling load status reporting and overcurrent protection preventing load short circuit damage.

- Manual Override: Optional manual load control allowing user intervention for critical situations.

Comprehensive System Protection

By integrating load management with battery protection, APTPCB delivers assemblies maintaining system reliability and protecting expensive battery investments through comprehensive control functions.

Providing Environmental Protection for Outdoor Use

Charge controllers operate in challenging outdoor environments—roof installations, remote cabins, marine vessels—experiencing temperature extremes, humidity, dust, and vibration requiring robust environmental protection ensuring long-term reliability.

APTPCB implements comprehensive protection processes for outdoor electronics.

Key Environmental Protection Methods

- Conformal Coating Application: PCB conformal coating with moisture-resistant materials protecting circuits from humidity, salt spray, and dust accumulation.

- Enhanced Component Selection: Industrial-grade components rated for extended temperature ranges (-40°C to +70°C) ensuring reliable operation across climates.

- Thermal Management: Heat dissipation strategies maintaining safe operating temperatures in sealed enclosures during high-power operation.

- Connector Protection: Industrial connectors with proper sealing maintaining electrical integrity despite environmental exposure.

- UV-Resistant Materials: PCB soldermask and enclosure materials resisting UV degradation in direct sunlight exposure.

- Vibration Resistance: Component attachment methods and PCB mounting withstanding transportation and installation vibration.

Long-Term Field Reliability

Through environmental protection and special PCB manufacturing, APTPCB delivers charge controller assemblies surviving 10-15 years of continuous outdoor operation.

Integrating Communication and Monitoring Interfaces

Modern charge controllers provide system monitoring through LCD displays, LED indicators, and digital communication interfaces enabling remote monitoring and data logging. Communication capabilities support system optimization, troubleshooting, and performance verification.

APTPCB implements diverse interface options supporting user requirements.

Key Interface Implementation

- Display Integration: LCD or LED displays showing system status, battery voltage, charging current, and fault conditions.

- Communication Protocols: RS-485, Modbus, CAN bus, or wireless interfaces supporting remote monitoring and system integration.

- Data Logging: Optional SD card or cloud connectivity recording system performance for analysis and optimization.

- Alarm Outputs: Relay or transistor outputs signaling fault conditions enabling external alarm systems.

- PC/Mobile Software: Compatible communication protocols supporting manufacturer-provided monitoring software.

- Firmware Updates: Updateable firmware allowing feature enhancements and bug fixes post-deployment.

Enhanced System Visibility

Through integrated communication and functional testing validation, APTPCB delivers assemblies providing comprehensive system monitoring supporting optimal operation.

Executing Comprehensive Testing for Charge Controllers

Charge controller validation requires testing charging algorithms, protection circuits, load switching, and communication interfaces across varying solar and battery conditions. Thorough testing prevents field failures and ensures reliable system operation.

APTPCB provides dedicated test capabilities validating all controller functions.

Key Testing Requirements

- Charging Algorithm Validation: Verifying voltage regulation, current limiting, and stage transitions across battery types and charging conditions.

- Protection Circuit Testing: Triggering overvoltage, overcurrent, short circuit, reverse polarity, and thermal conditions verifying protective responses.

- Load Switching Verification: Testing load connect/disconnect thresholds, current handling capacity, and switching reliability.

- Temperature Compensation: Validating automatic voltage adjustment across temperature ranges ensuring proper battery charging.

- Communication Testing: Verifying interface protocols, data accuracy, and alarm functions ensuring reliable monitoring.

- Environmental Stress: Temperature cycling and burn-in testing identifying early failures and validating long-term reliability.

Validated Controller Performance

Through comprehensive testing and quality inspection, APTPCB delivers charge controller assemblies meeting specifications and reliability requirements.

Supporting Diverse Market Requirements

Charge controller markets span residential off-grid systems, recreational vehicles, marine vessels, telecommunications, and remote industrial installations requiring manufacturing flexibility supporting diverse specifications, certifications, and customization needs.

APTPCB provides scalable production from development through volume manufacturing.

Key Production Capabilities

- Rapid Prototyping: NPI assembly delivering functional prototypes supporting design validation and certification testing.

- Custom Configurations: Flexible assembly accommodating power ratings, feature options, and interface variants serving specific market segments.

- Volume Production: Mass production capability supporting thousands of units annually with consistent quality and competitive pricing.

- Component Engineering: Component sourcing managing MOSFETs, regulators, and specialized components ensuring material availability.

- Certification Support: Manufacturing documentation and testing supporting UL, CE, and regional certifications enabling global market access.

- Technical Support: Engineering assistance with design optimization, test development, and manufacturing throughout product lifecycle.

Flexible Manufacturing Partnership

Through responsive capabilities and support services, APTPCB enables charge controller manufacturers serving diverse markets efficiently. Our power energy experience supports successful solar product programs globally.