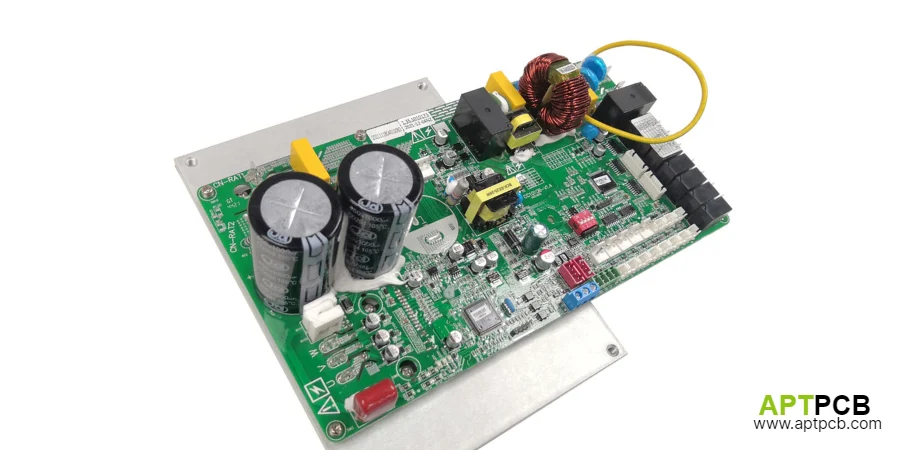

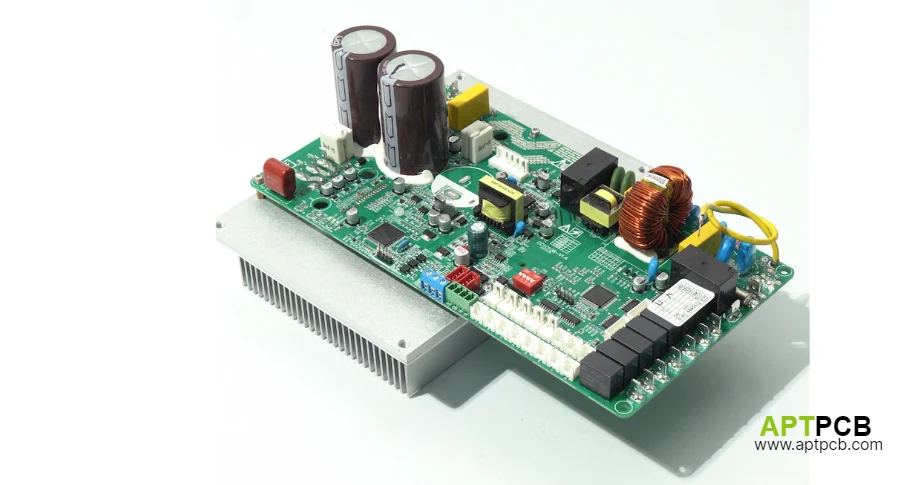

Solar inverter control PCBs implement sophisticated digital algorithms managing power conversion, grid synchronization, and system protection requiring precision mixed-signal design and reliable manufacturing. Control electronics determine inverter efficiency, power quality, and safety response making PCB quality critical for system performance and regulatory compliance across residential, commercial, and utility-scale installations.

At APTPCB, we manufacture solar inverter control PCBs with expertise in multilayer PCB design, precision assembly, and comprehensive testing. Our manufacturing capabilities support DSP-based control, communication interfaces, and sensor conditioning delivering reliable control electronics for photovoltaic power conversion.

Implementing Precision Mixed-Signal Design in Control PCBs

Inverter control boards integrate high-speed digital processors with sensitive analog sensing requiring careful PCB design separating noise sources from precision circuits. Poor layout causes measurement errors, control instability, or EMI issues degrading inverter performance or causing grid compliance failures.

At APTPCB, our control PCB manufacturing implements signal integrity design principles and validated processes.

Key Mixed-Signal Design Requirements

- Analog-Digital Separation: PCB stack-up designs with separate ground planes or star grounding preventing digital switching noise coupling into analog sensor circuits.

- Precision Reference Distribution: Low-noise voltage references and power supply filtering maintaining measurement accuracy for current, voltage, and temperature sensing critical to control algorithms.

- High-Speed Digital Routing: Controlled impedance traces and proper termination for DSP, FPGA, or microcontroller high-speed interfaces preventing signal integrity issues.

- Shielding and Guard Rings: Strategic copper shielding and guard ring implementation isolating sensitive analog inputs from noisy digital sections and power switching.

- Decoupling Strategy: Comprehensive power supply decoupling with proper capacitor selection and placement maintaining clean power rails across frequency spectrum.

- Layout Verification: Signal integrity simulation and pre-production validation ensuring designs meet timing, noise immunity, and EMC requirements.

Reliable Digital Control Performance

Through precision PCB fabrication processes and validated manufacturing, APTPCB enables inverter control achieving measurement accuracy better than 0.5% and control loop bandwidths exceeding 10kHz supporting high-performance power conversion.

Managing Communication Interface Integration

Modern inverters require multiple communication interfaces—RS-485 for local monitoring, Ethernet/WiFi for internet connectivity, and CAN bus for system integration. Interface circuits must provide reliable data transmission with proper isolation and ESD protection operating in electrically noisy photovoltaic environments.

APTPCB implements robust communication interface manufacturing with protection and testing.

Key Communication Interface Elements

- Galvanic Isolation: Isolated transceivers and power supplies achieving 2.5kV+ isolation between communication ports and high-voltage inverter sections meeting safety requirements.

- ESD Protection: Multi-stage ESD suppression and transient protection preventing damage from electrostatic discharge or induced surges common in outdoor solar installations.

- Impedance Matching: Controlled impedance routing and proper termination for Ethernet, CAN bus, and high-speed serial interfaces ensuring reliable communication.

- Connector Selection: Industrial-grade connectors with proper shielding and environmental sealing maintaining signal integrity and mechanical reliability.

- Protocol Stack Validation: Testing communication interfaces verifying protocol compliance, data integrity, and error handling under various network conditions.

- Firmware Programming: Communication firmware and configuration parameters loaded during assembly.

Robust Field Communication

Through proper interface design and manufacturing, APTPCB delivers control PCBs achieving >99.9% communication reliability supporting remote monitoring, firmware updates, and system diagnostics essential for modern photovoltaic installations.

Ensuring Environmental Durability in Control Electronics

Control PCBs operate alongside power stages in inverter enclosures experiencing elevated temperatures, humidity, and potential contamination requiring environmental protection without compromising signal quality or thermal performance.

APTPCB applies protective measures tailored for solar control electronics.

Key Environmental Protection Techniques

- Conformal Coating Application: Selective PCB conformal coating protecting circuits while avoiding connectors, test points, and areas requiring heat dissipation.

- Material Selection: High-Tg PCB laminates maintaining dimensional stability and electrical performance during temperature cycling in outdoor installations.

- Surface Finish Protection: Enhanced surface finishes providing superior corrosion resistance and maintaining solderability over extended storage periods.

- Moisture Sensitivity Management: Baking and packaging protocols preventing moisture absorption in components during storage and assembly.

- Environmental Testing: Humidity, thermal cycling, and salt spray qualification validating long-term reliability in harsh outdoor conditions.

- Cleaning Validation: Ionic contamination testing ensuring residue removal preventing insulation resistance degradation in high-voltage environments.

Long-Term Outdoor Reliability

By implementing comprehensive environmental protection and special PCB manufacturing processes, APTPCB delivers control electronics surviving 25+ years of outdoor operation.

Executing Functional Testing for Control Electronics

Control PCB testing must verify analog measurement accuracy, digital processing, communication interfaces, and protection circuits ensuring complete functionality before integration into inverter assemblies. Inadequate testing results in field failures or commissioning issues.

APTPCB provides comprehensive test capabilities validating all control functions.

Key Control Testing Requirements

- Analog Signal Chain Testing: Verifying current, voltage, and temperature measurement accuracy across operating ranges with calibrated instrumentation.

- Digital Processing Validation: Testing DSP, FPGA, or microcontroller operation including memory, peripherals, and calculation accuracy.

- Communication Interface Testing: Validating RS-485, Ethernet, WiFi, and CAN bus communication with protocol analyzers and network simulators.

- Protection Circuit Verification: Testing fault detection, alarm generation, and shutdown sequences ensuring proper protection response.

- Firmware Functionality: Validating control algorithms, user interfaces, and system integration.

- Environmental Stress: Temperature cycling and burn-in identifying early failures before shipment.

Validated Control Performance

Through comprehensive testing with AOI inspection, APTPCB delivers control PCBs meeting accuracy, reliability, and performance specifications.

Supporting Rapid Product Development Cycles

Solar inverter markets evolve rapidly with new grid codes, efficiency requirements, and feature expectations requiring manufacturers adapting products quickly. Manufacturing partners must support rapid prototyping, responsive engineering, and flexible production.

APTPCB provides agile manufacturing supporting solar inverter development programs.

Key Development Support Capabilities

- Quick Turn Prototyping: Quick turn PCB fabrication and assembly delivering prototypes in 7-10 days supporting rapid design iterations.

- DFM Collaboration: Design review and optimization suggestions improving manufacturability and reducing costs before production commitment.

- Test Development: Custom test fixture design and programming automating functional validation during production.

- Engineering Change Management: Responsive accommodation of design revisions and component changes supporting continuous product improvement.

- Volume Transition: Smooth scaling from prototypes to pilot production and volume manufacturing maintaining consistent quality.

- Technical Support: Engineering assistance troubleshooting issues and optimizing designs throughout development and production phases.

Accelerated Time to Market

Through flexible manufacturing and support services, APTPCB enables solar inverter manufacturers responding quickly to market opportunities. Our power energy industry experience supports successful product development and launches.

Maintaining Quality and Certification Compliance

Solar inverter control electronics require compliance with safety standards (UL, IEC), EMC regulations, and grid interconnection codes. Manufacturing processes and documentation must support certification programs and maintain compliant production.

APTPCB provides quality systems and documentation enabling regulatory compliance.

Key Quality and Compliance Elements

- Process Controls: IPC Class 3 manufacturing with documented procedures ensuring consistent production.

- Material Traceability: Lot tracking supporting certification requirements and failure investigations.

- Test Documentation: Comprehensive test records and certificates of conformance demonstrating compliance with specifications.

- First Article Inspection: Documentation with dimensional verification, electrical testing, and functional validation supporting customer qualifications.

- Change Control: Formal engineering change processes maintaining configuration control and certification validity.

- Audit Support: Supporting customer and certification body audits with documented procedures and records.

Streamlined Certification Success

By combining manufacturing capability with comprehensive quality inspection and documentation, APTPCB accelerates solar inverter certifications enabling efficient compliance achievement supporting global market access.