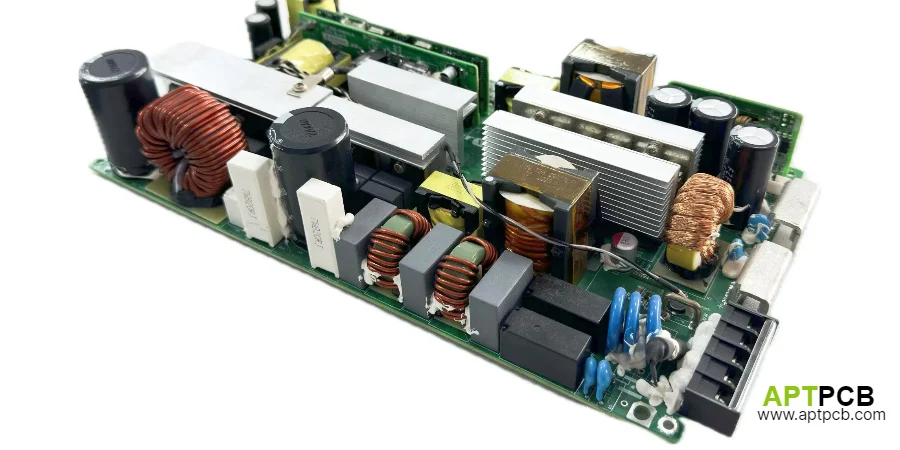

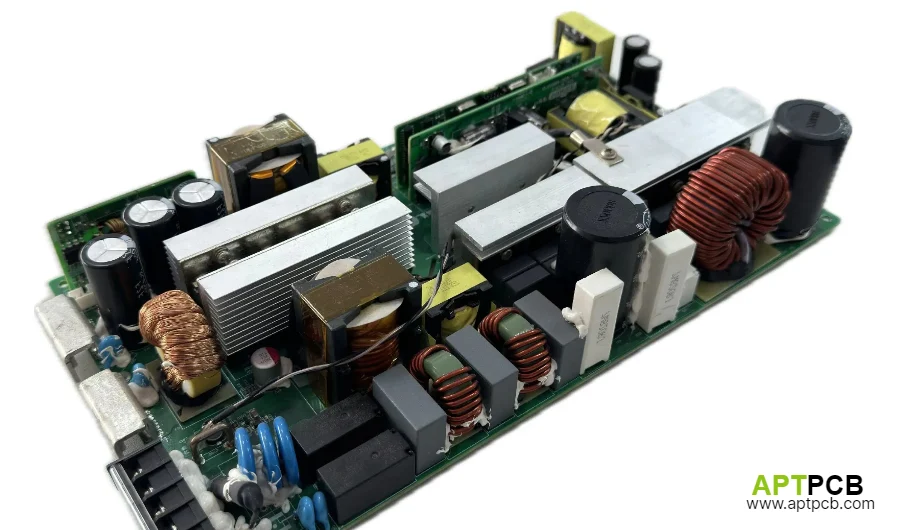

Solar inverter power stage PCBs handle kilowatts to megawatts of power conversion requiring robust construction, superior thermal management, and high-voltage design expertise. These boards must reliably switch DC power at 600-1000VDC converting to AC grid voltage while managing heat dissipation, minimizing losses, and withstanding 25+ years of continuous outdoor operation under varying environmental conditions.

At APTPCB, we specialize in manufacturing solar inverter power PCBs implementing heavy copper technology, advanced thermal management, and high-voltage design rules. Our capabilities support string inverters, central inverters, and hybrid systems delivering reliable power conversion for residential through utility-scale installations.

Implementing Heavy Copper Construction for Power Handling

Power stage PCBs carry continuous currents from 20A to 200A+ requiring heavy copper layers distributing current without excessive resistance or heating. Inadequate copper weight causes voltage drop, efficiency loss, and thermal failures degrading inverter performance and reliability.

At APTPCB, we implement multi-ounce copper construction optimized for high-current power distribution.

Key Heavy Copper Requirements

- Copper Weight Selection: 3-6oz outer layers and 2-4oz inner layers providing current capacity for DC bus distribution and AC output without thermal limitations.

- Current Density Management: Design rules limiting current density to 30-50A per ounce copper maintaining safe operating temperatures under maximum load conditions.

- Plated Through-Hole Design: Multiple large PTHs in parallel distributing current between layers with low resistance and high reliability under thermal cycling.

- Bus Bar Integration: PCB features accommodating copper or aluminum bus bars for highest-current connections reducing resistance and improving thermal performance.

- Manufacturing Process Control: Specialized fabrication handling thick copper with controlled etching and plating maintaining design dimensions.

- Thermal Expansion Management: High-Tg materials accommodating CTE differences between heavy copper and laminate preventing delamination during temperature cycling.

Reliable High-Current Distribution

Through heavy copper expertise and advanced PCB manufacturing, APTPCB delivers power stage PCBs handling maximum rated currents with minimal voltage drop and controlled temperature rise.

Managing Thermal Performance in High-Power Designs

Solar inverter power stages dissipate 100W to several kilowatts as heat requiring effective thermal management preventing component overheating and maintaining efficiency. Poor thermal design causes derating, premature failure, or safety shutdown reducing energy production and system reliability.

APTPCB implements comprehensive thermal strategies from materials through validation testing.

Key Thermal Management Techniques

- Metal Core PCB Option: Metal core PCB construction for highest-power applications providing superior thermal conductivity and reduced junction temperatures.

- Thermal Via Arrays: High-density thermal via patterns beneath IGBT, MOSFET, and diode packages transferring heat from devices to heat sink interface or opposite layer.

- Copper Plane Optimization: Large copper pours on external layers spreading heat across board area reducing peak temperatures and hot spots.

- Heat Sink Interface Design: PCB mounting features and thermal pad specifications ensuring proper mechanical and thermal coupling to external cooling systems.

- Thermal Simulation Validation: Pre-production modeling predicting temperature distribution identifying design improvements before manufacturing investment.

- Material Thermal Conductivity: High thermal PCB materials and thermal interface materials optimizing heat transfer from semiconductors through PCB to cooling system.

Controlled Operating Temperatures

By combining thermal design expertise with manufacturing capability, APTPCB enables power stage PCBs maintaining semiconductor junction temperatures within specifications during maximum power operation.

Ensuring High-Voltage Safety and Reliability

Solar power stages operate at DC voltages up to 1000V requiring enhanced creepage, clearance, and isolation preventing electrical breakdown or tracking. High-voltage design errors create safety hazards, certification failures, or field breakdowns with serious consequences.

APTPCB implements high-voltage design rules and manufacturing controls ensuring electrical safety.

Key High-Voltage Design Elements

- Enhanced Spacing Rules: Creepage and clearance distances per IEC 62109 maintaining minimum separation between high-voltage traces and other conductors.

- Isolation Barriers: Multilayer PCB stackups with dedicated isolation layers achieving reinforced isolation between DC and AC sections.

- Material Selection: High CTI laminate materials resisting carbon tracking and maintaining insulation resistance in humid outdoor environments.

- Soldermask Protection: Enhanced soldermask coverage and thickness protecting conductors from environmental exposure and preventing surface tracking.

- Partial Discharge Validation: Manufacturing qualification through corona testing ensuring designs withstand continuous high-voltage stress without degradation.

- Hi-Pot Testing: Production testing verifying insulation resistance and dielectric strength between isolated sections ensuring safety compliance.

Long-Term Voltage Withstand

Through high-voltage design expertise and PCB quality processes, APTPCB manufactures power stage PCBs maintaining electrical isolation and safety throughout 25-year operational lifetimes.

Optimizing Layout for Power Conversion Efficiency

Power stage layout significantly impacts inverter efficiency through parasitic inductance, switching losses, and EMI generation. Careful component placement and routing minimize these effects maximizing energy conversion and reducing filtering requirements.

APTPCB provides layout optimization supporting high-efficiency power conversion.

Key Layout Optimization Techniques

- Switching Loop Minimization: Compact placement of switches, diodes, and capacitors minimizing parasitic inductance reducing voltage ringing and switching losses.

- Gate Drive Optimization: Short, low-inductance gate drive routing enabling fast switching transitions while preventing oscillation or cross-conduction.

- Symmetrical Layout: Balanced current paths in multi-phase designs ensuring equal current sharing and thermal distribution across parallel devices.

- EMI Control: Strategic component orientation and grounding managing common-mode currents reducing conducted and radiated emissions.

- Sense Circuit Placement: Current and voltage sensing circuits located for accurate measurement while maintaining isolation from switching noise.

- Manufacturing Validation: First article inspection and electrical testing verifying layout meets efficiency and performance specifications.

Maximum Energy Conversion

Through optimized layout and validated manufacturing, APTPCB delivers power stage PCBs enabling inverter efficiency >98% at rated power.

Supporting Global Solar Standards Compliance

Solar inverter power stages require compliance with safety standards (UL 1741, IEC 62109), EMC regulations, and grid codes globally. Manufacturing processes and documentation must support certification programs and maintain compliant production.

APTPCB provides comprehensive support for solar certifications.

Key Compliance Support Elements

- Safety Design Rules: Manufacturing per IPC Class 3 standards with enhanced spacing supporting safety agency requirements and testing.

- Material Documentation: Complete RoHS, REACH, and material declarations enabling global market access and regulatory compliance.

- Process Traceability: Lot tracking and incoming quality control documentation supporting certification audits and failure investigation.

- Test Records: Comprehensive electrical and thermal test data demonstrating compliance with specifications and standards.

- Change Control: Formal engineering change processes maintaining production consistency and certification validity.

- Certification Support: Technical assistance during certification testing and coordination with testing laboratories.

Streamlined Global Certification

By combining manufacturing expertise with comprehensive quality systems, APTPCB accelerates solar inverter certifications enabling efficient multi-region certification supporting worldwide installations.

Delivering Scalable Production for Solar Markets

Solar inverter production spans low-volume specialized systems through high-volume residential products requiring manufacturing flexibility and competitive pricing. Manufacturing partners must support development, pilot production, and volume scaling.

APTPCB provides flexible production from prototypes through mass manufacturing.

Key Production Flexibility Capabilities

- Rapid Prototyping: Quick turn PCB fabrication delivering prototypes in 5-7 days supporting design validation and certification testing.

- NPI Support: NPI manufacturing processes enabling smooth transition from development through pilot production maintaining consistent quality.

- Volume Production: Mass production capability supporting thousands to millions of units annually with competitive pricing and reliable delivery.

- DFM Optimization: Collaborative design review identifying cost reduction opportunities while maintaining performance and reliability requirements.

- Supply Chain Management: Component sourcing strategies and inventory programs ensuring material availability supporting production schedules.

- Engineering Support: Technical assistance with design optimization, manufacturing issues, and continuous improvement throughout product lifecycle.

Reliable Solar Manufacturing Partnership

Through scalable manufacturing and responsive support, APTPCB enables solar inverter manufacturers focusing on power conversion technology while we deliver reliable PCBs from concept through volume production.