Solar LED driver PCBs enable efficient off-grid lighting systems converting battery DC voltage to regulated LED current with intelligent control features including dusk-to-dawn operation, motion sensing, and dimming capabilities. These drivers must achieve high efficiency (>90%), withstand outdoor environmental exposure, and provide 50,000+ hour operational lifetimes matching LED expectations in street lighting, area illumination, and remote applications.

At APTPCB, we manufacture solar LED driver PCBs implementing constant current regulation, protection circuits, and intelligent control features. Our manufacturing capabilities support compact designs, thermal management, and environmental protection delivering reliable solar lighting solutions.

Implementing High-Efficiency Constant Current LED Drive

LED performance and lifetime depend on precise current regulation preventing overcurrent damage while maintaining consistent brightness across battery voltage variations and temperature changes. Inefficient drivers waste limited solar energy reducing system performance and runtime.

At APTPCB, our manufacturing implements optimized power conversion topologies and component selection.

Key Efficiency Optimization Techniques

- Topology Selection: Buck, boost, or buck-boost converter implementations matching LED string voltage to battery voltage minimizing conversion losses.

- Synchronous Rectification: MOSFET-based synchronous rectifiers replacing diodes eliminating forward voltage drops improving efficiency especially at low voltages.

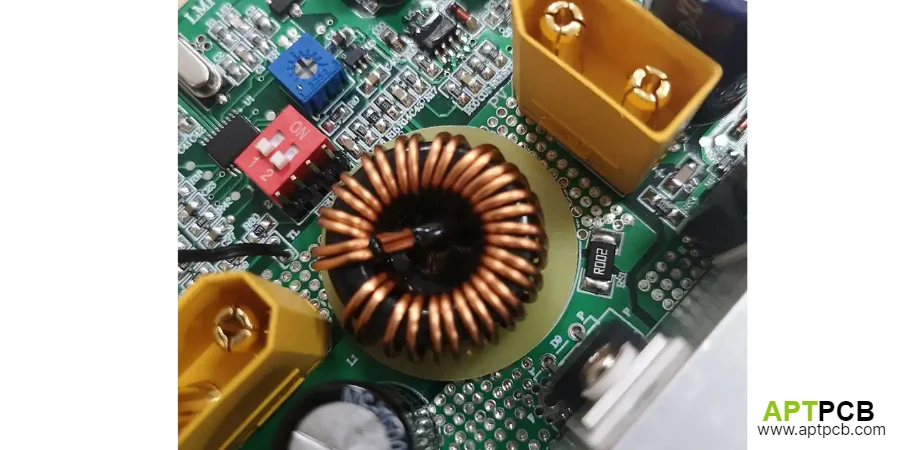

- Inductor Optimization: Custom inductor designs balancing DCR, saturation current, and core losses achieving maximum energy transfer efficiency.

- Low RDS-ON MOSFETs: Power switch selection emphasizing low on-resistance reducing conduction losses during switching operation.

- PCB Layout Optimization: HDI PCB construction with optimized current paths minimizing resistive losses and parasitic inductance.

- Thermal Management: Heat dissipation enabling continuous operation without efficiency-degrading thermal derating.

Maximum Energy Utilization

Through efficiency-focused manufacturing and advanced PCB manufacturing, APTPCB delivers LED driver PCBs achieving >92% efficiency maximizing illumination hours from limited solar energy.

Integrating Intelligent Lighting Control Features

Solar LED systems benefit from intelligent control maximizing energy efficiency through dimming, motion detection, and adaptive brightness maintaining illumination while extending battery runtime. Control implementation requires microcontroller integration, sensor interfaces, and validated firmware.

APTPCB manufactures LED drivers with comprehensive control capabilities.

Key Intelligent Control Features

- Dusk-to-Dawn Operation: Ambient light sensing automatically controlling LED operation without manual intervention optimizing energy usage.

- Motion Detection: PIR sensor integration enabling full brightness when motion detected and dimmed mode otherwise extending runtime significantly.

- Adaptive Dimming: Battery voltage monitoring adjusting LED brightness preventing over-discharge while maintaining minimum illumination levels.

- Time-Based Profiles: Programmable brightness schedules optimizing illumination patterns for specific applications and usage profiles.

- Temperature Compensation: LED current adjustment compensating for temperature effects maintaining consistent light output and preventing thermal stress.

- Remote Control Options: Wireless interfaces enabling remote configuration, monitoring, and control for smart city applications.

Optimized Energy Management

By integrating intelligent control through SMT assembly and firmware programming, APTPCB enables LED drivers achieving 2-3x runtime extension through adaptive operation.

Providing Thermal Management for LED Power Electronics

LED drivers dissipate heat from power conversion requiring effective thermal management preventing component overheating and maintaining efficiency. Inadequate thermal design causes premature failure, reduced efficiency, or safety shutdown in compact sealed enclosures.

APTPCB implements comprehensive thermal strategies for LED driver applications.

Key Thermal Management Approaches

- Copper Distribution: Heavy copper PCB construction with 2-3oz layers spreading heat from power components across board area.

- Thermal Via Implementation: Dense thermal via arrays beneath MOSFETs and inductors conducting heat through PCB to mounting surfaces or heat sinks.

- Component Placement: Strategic spacing and orientation maximizing thermal coupling to enclosure or external cooling systems.

- Heat Sink Interface: PCB mounting features and thermal pad specifications ensuring effective mechanical and thermal coupling.

- Material Selection: High thermal conductivity materials and thermal interface compounds optimizing heat transfer paths.

- Thermal Validation: Temperature measurement and infrared imaging verifying designs maintain safe operating temperatures under worst-case conditions.

Reliable Thermal Performance

Through thermal engineering and validated manufacturing, APTPCB delivers LED driver PCBs maintaining safe junction temperatures during continuous operation in sealed outdoor enclosures.

Ensuring Environmental Protection and Reliability

Solar LED drivers require enhanced environmental protection surviving years of outdoor exposure to moisture, temperature cycling, dust, and UV radiation. Inadequate protection causes premature failures requiring maintenance in difficult-to-access locations.

APTPCB implements comprehensive environmental protection processes.

Key Protection Implementation

- Conformal Coating: Moisture-resistant coating protecting circuits from humidity and dust accumulation in outdoor installations.

- Enhanced Surface Finishes: Corrosion-resistant finishes maintaining solder joint integrity and electrical connections over extended periods.

- UV-Resistant Materials: PCB soldermask and materials resisting UV degradation from continuous sunlight exposure.

- Wide Temperature Components: Component selection supporting -40°C to +85°C operation across diverse geographic deployments.

- Vibration Resistance: Component attachment withstanding wind-induced vibration in street light and area lighting installations.

- Environmental Testing: Accelerated humidity, temperature cycling, and salt spray testing validating 10+ year outdoor lifetime predictions.

Long-Term Outdoor Survival

Through comprehensive protection and PCB quality systems, APTPCB delivers LED driver assemblies surviving extended outdoor operation matching LED lifetime expectations.

Executing Comprehensive Functional Testing

LED driver validation requires testing current regulation accuracy, efficiency, control functions, and protection circuits across varying input voltages and operating conditions. Thorough testing prevents field failures and ensures reliable operation.

APTPCB provides dedicated LED driver test capabilities.

Key Testing Requirements

- Current Regulation Testing: Verifying LED current accuracy and stability across input voltage ranges and temperature variations.

- Efficiency Measurement: Testing conversion efficiency at multiple operating points validating >90% efficiency targets.

- Control Function Validation: Verifying dimming operation, sensor interfaces, and intelligent control algorithms under realistic conditions.

- Protection Circuit Testing: Triggering overvoltage, overcurrent, short circuit, and thermal conditions verifying protective responses.

- LED Compatibility: Testing with various LED configurations verifying proper operation and protection across applications.

- Environmental Stress: Functional testing with temperature cycling identifying early failures and validating reliability.

Validated Driver Performance

Through comprehensive testing and incoming quality control, APTPCB delivers LED driver PCBs meeting efficiency, regulation accuracy, and reliability specifications.

Supporting Cost-Effective Volume Production

Solar LED driver markets demand competitive pricing while maintaining quality and reliability requirements. Manufacturing optimization must reduce costs without compromising the 10+ year operational lifetime required for outdoor lighting installations.

APTPCB implements cost optimization strategies balanced with reliability.

Key Cost Optimization Approaches

- Design for Manufacturing: Collaborative DFM review identifying cost reduction opportunities through component standardization and process optimization.

- Volume Production: Mass production PCB manufacturing with optimized panel utilization reducing per-unit material costs.

- Component Sourcing: Strategic procurement of power semiconductors and inductors achieving competitive pricing while ensuring authentic parts.

- Process Efficiency: Automated manufacturing processes reducing labor costs while maintaining consistent quality.

- Test Optimization: Efficient test strategies validating critical functions without excessive testing costs.

- Supply Chain Management: Inventory programs and volume commitments ensuring material availability and pricing stability.

Competitive Manufacturing Economics

By combining efficiency with quick turn PCB prototyping and mass production capability, APTPCB delivers LED driver PCBs at competitive costs supporting market success in solar lighting applications.