Solar PCB assembly requires specialized manufacturing processes ensuring electronics withstand decades of outdoor exposure while maintaining high efficiency and safety compliance. Unlike consumer electronics assembled in controlled environments with 3-5 year lifespans, solar assemblies must survive temperature extremes, moisture intrusion, and UV exposure operating continuously for 25+ years matching solar panel warranties without maintenance access.

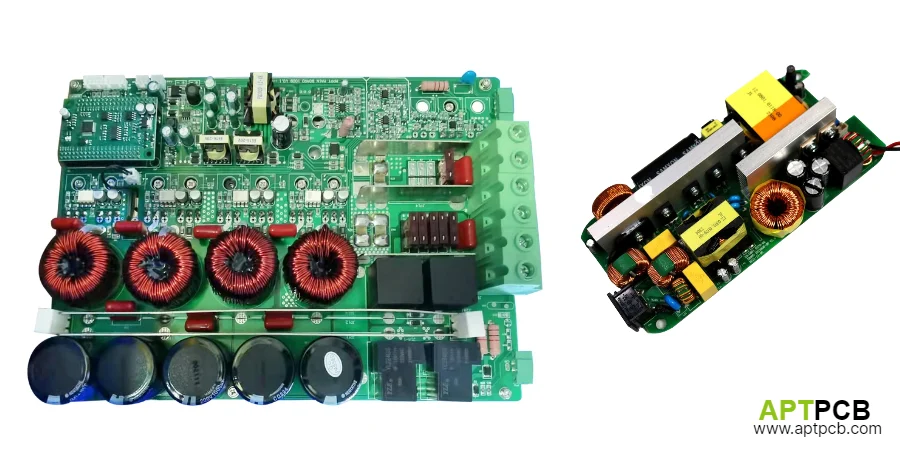

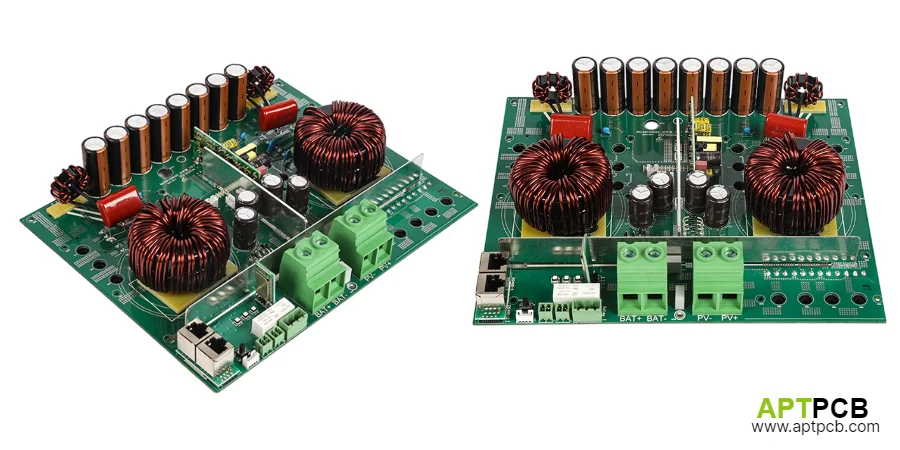

At APTPCB, we provide comprehensive assembly services for solar electronics combining enhanced manufacturing processes, environmental protection, and validation testing. Our capabilities span microinverters, string inverters, MPPT controllers, and monitoring electronics supporting residential through utility-scale installations.

Implementing High-Reliability Assembly for Solar Electronics

Solar assembly processes must exceed standard commercial practices implementing enhanced controls preventing defects that could cause premature failure in outdoor installations. Moisture ingress, solder joint degradation, or component failures generate warranty claims and system downtime impacting customer satisfaction and manufacturer profitability.

At APTPCB, our solar assembly expertise implements IPC Class 3 standards with additional controls ensuring long-term reliability.

Key High-Reliability Assembly Practices

- Moisture-Controlled Environment: Climate-controlled assembly areas maintaining <50% humidity preventing moisture absorption in PCBs and components before conformal coating application.

- Enhanced Solder Joint Quality: SMT assembly with controlled reflow profiles and nitrogen atmosphere ensuring complete wetting and eliminating voids in thermal pads critical for power devices.

- Component Authentication: Procuring power semiconductors, capacitors, and critical components through authorized channels preventing counterfeit parts compromising reliability.

- Soldering Process Validation: Regular thermal profiling and solder joint cross-sectioning verifying process capability and maintaining consistent quality across production volumes.

- Cleaning and Contamination Control: No-clean or aqueous cleaning removing flux residues that could compromise insulation resistance or attract moisture in high-voltage sections.

- Handling and ESD Protection: Strict ESD controls and handling procedures preventing latent damage to sensitive components like MOSFETs and control ICs.

Decades-Long Reliability Achievement

By implementing enhanced assembly controls and quality systems, APTPCB delivers solar electronics achieving field failure rates <0.1% annually supporting 25-year warranties. Our testing and quality processes ensure every assembly meets stringent photovoltaic industry reliability requirements.

Executing Comprehensive Functional Testing for Solar Assemblies

Solar electronics require validation beyond standard PCB testing—functional testing must verify power conversion efficiency, MPPT algorithms, grid synchronization, and protection circuits under realistic operating conditions. Inadequate testing results in field failures, efficiency losses, or safety hazards requiring expensive recalls or warranty replacements.

APTPCB provides dedicated test capabilities validating solar electronics performance comprehensively.

Key Solar Testing Requirements

- Power Conversion Efficiency: Testing under varying input voltages and load conditions verifying >98% peak efficiency and ensuring compliance with CEC or European efficiency specifications.

- MPPT Algorithm Validation: Simulating solar panel I-V curves testing maximum power point tracking accuracy and speed under varying irradiance conditions.

- Grid Synchronization Testing: Validating phase-locked loop operation, voltage/frequency compliance, and anti-islanding protection meeting UL 1741 or IEC 62109 requirements.

- Protection Circuit Verification: Testing overvoltage, overcurrent, ground fault, and arc fault detection ensuring protective functions activate properly preventing fire or shock hazards.

- Communication Interface Testing: Verifying RS-485, CAN bus, or WiFi monitoring interfaces ensuring reliable data transmission for system monitoring and optimization.

- Environmental Stress Screening: Temperature cycling and burn-in testing identifying infant mortality failures before shipment improving field reliability.

Validated Performance and Safety

Through comprehensive functional testing and quality inspection, APTPCB delivers solar assemblies meeting efficiency specifications, safety standards, and reliability requirements. Our solar electronics expertise supports successful product launches and field deployments across global photovoltaic markets.

Providing Environmental Protection Through Conformal Coating

Solar electronics require protective conformal coating preventing moisture intrusion, dust accumulation, and corrosion in outdoor installations. Proper coating application maintains insulation resistance, protects solder joints, and extends operational lifetime without compromising thermal dissipation or rework ability.

APTPCB implements conformal coating processes optimized for solar electronics protection requirements.

Key Conformal Coating Techniques

- Material Selection: Applying acrylic, silicone, or polyurethane coatings matched to application requirements balancing moisture protection, thermal performance, and rework feasibility.

- Selective Coating Application: Masking connectors, heat sinks, and test points while coating circuit areas requiring environmental protection preventing coating interference with thermal or electrical functions.

- Application Process Control: Automated or manual coating with controlled thickness (50-150μm) ensuring complete coverage without excessive buildup affecting heat dissipation or component clearance.

- Curing and Validation: Proper curing cycles ensuring full polymerization and coating adhesion validated through pull tests and insulation resistance measurement.

- Coverage Inspection: Visual and UV fluorescent inspection verifying complete coating coverage without voids, runs, or excessive buildup affecting reliability.

- Thermal Performance Verification: Thermal testing confirming coating doesn't compromise heat dissipation from power devices maintaining safe operating temperatures.

Enhanced Environmental Durability

By implementing professional conformal coating processes, APTPCB protects solar assemblies from humidity, salt spray, and contaminants extending operational lifetime in harsh outdoor environments. Our coating expertise ensures solar electronics survive coastal, tropical, and high-humidity installations maintaining performance throughout 25-year service lives.

Supporting Scalable Production from Prototypes to Volume

Solar electronics production spans low-volume custom solutions through high-volume standardized products requiring manufacturing flexibility accommodating market uncertainties and technology evolution. Manufacturing partners must support rapid prototyping, efficient volume production, and responsive engineering throughout product lifecycles.

APTPCB provides scalable solar assembly from development through mass production.

Key Production Flexibility Capabilities

- Rapid Prototype Assembly: NPI assembly services delivering prototype quantities in 7-10 days supporting design validation and certification testing.

- NPI to Production Transition: Smooth scaling from engineering builds to pilot production and volume manufacturing maintaining consistent processes and quality.

- Volume Production Capacity: Mass production capability supporting volumes from 1,000 to 100,000+ units annually with competitive pricing and reliable delivery.

- Multi-Product Management: Handling product families with shared platforms and custom variants through flexible assembly lines and inventory systems.

- Supply Chain Management: Component procurement with authorized distributors, buffer inventory, and obsolescence monitoring ensuring material availability.

- Engineering Support: DFM optimization, test development, and troubleshooting assistance accelerating product development and production launches.

Reliable Solar Manufacturing Partnership

Through flexible production capabilities and support services, APTPCB enables solar electronics manufacturers focusing on technology development while we deliver reliable assemblies from concept through volume production. Our power energy industry experience supports successful solar product programs.

Enabling Global Market Access Through Certification Support

Solar electronics require compliance with diverse regional standards—UL 1741 (North America), IEC 62109 (Europe/International), VDE-AR-N 4105 (Germany), and country-specific grid codes enabling installations globally. Assembly processes and documentation must support certification programs and maintain compliant production.

APTPCB provides manufacturing support facilitating solar product certifications worldwide.

Key Certification Support Elements

- Traceable Manufacturing: Complete lot tracking and incoming quality control documentation supporting certification body audits and failure investigations.

- Material Compliance: RoHS, REACH, and conflict mineral declarations enabling European market access and meeting corporate sustainability requirements.

- Process Documentation: First article inspection reports and manufacturing travelers supporting PPAP submissions and customer qualifications.

- Test Data Records: Comprehensive functional test data and environmental test results demonstrating compliance with certification requirements.

- Change Control: Formal engineering change processes with documentation ensuring production consistency and maintaining certification validity.

- Supplier Audits: Supporting customer or certification body audits with documented quality systems and process controls.

Streamlined Global Certification

By combining manufacturing expertise with comprehensive documentation and quality inspection procedures, APTPCB accelerates solar product certifications. Our experience with international power energy applications enables efficient multi-region certification success supporting global market deployment.

Delivering Complete Turnkey Solutions

Solar electronics projects require more than assembly services—successful programs demand engineering collaboration, supply chain management, and testing development. Complete turnkey solutions accelerate time-to-market and reduce development risks.

APTPCB provides turnkey assembly services for solar electronics programs.

Key Turnkey Service Capabilities

- Component Procurement: Full BOM sourcing from authorized distributors managing long-lead items and securing competitive pricing.

- Engineering Collaboration: Technical support for design optimization, test fixture development, and manufacturing troubleshooting.

- Assembly and Testing: Complete SMT assembly, through-hole assembly, conformal coating, and functional testing under one roof.

- Quality Assurance: Comprehensive inspection protocols with AOI inspection and X-ray validation ensuring assembly quality.

- Logistics Management: PCB fabrication coordination, component delivery scheduling, and finished goods shipping simplifying supply chain management.

- Program Management: Dedicated project coordination ensuring clear communication and on-time delivery throughout production lifecycle.

Simplified Solar Electronics Development

Through complete turnkey services, APTPCB enables solar manufacturers focusing on product innovation and market development while we manage the complexities of electronics manufacturing, testing, and quality assurance supporting successful product launches and volume production.