Tablet PCB manufacturing supports larger form factors (7-13 inch displays) enabling more spacious layouts compared to smartphones while maintaining thin profiles (5-7mm) requiring HDI construction, high-performance processor integration, and battery management systems handling 5000-10000mAh capacities across consumer tablets, enterprise productivity devices, rugged industrial platforms, and educational computing requiring reliable operation supporting 3-5 year lifecycles with daily charging cycles, varied environmental conditions, and intensive display and processor usage patterns.

At APTPCB, we manufacture tablet PCBs with drone UAV precision implementing advanced stackups, thermal management, and validated manufacturing processes. Our capabilities support budget education tablets through flagship productivity devices with cellular connectivity, stylus digitizers, and desktop-class processors achieving performance and reliability specifications.

Optimizing Layout for Large-Format Designs

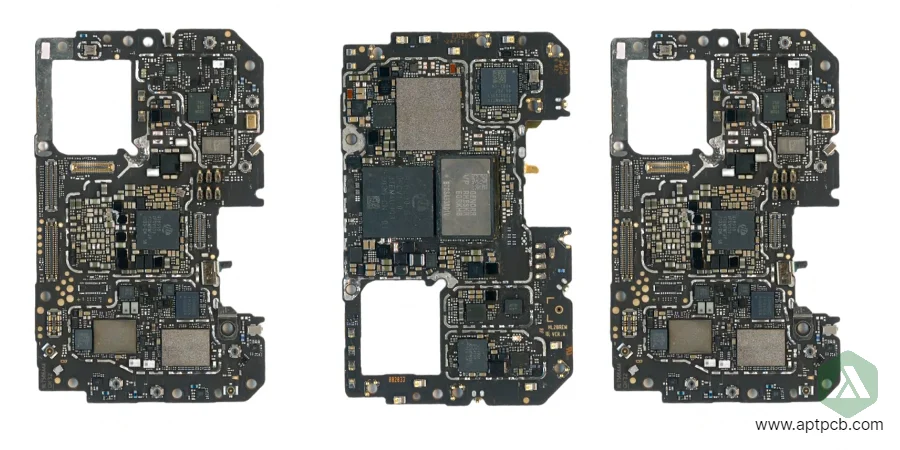

Tablet PCBs measuring 100-200mm lengths enable more generous component spacing compared to smartphones while still demanding efficient layout utilizing available board area for optimal battery placement, thermal management, and antenna performance. Layout challenges include managing high-speed processor interfaces across longer distances, distributing power efficiently minimizing voltage drops, and coordinating multiple subsystems (wireless, display, audio, sensors) preventing interference. Inadequate layout optimization wastes valuable space reducing battery capacity, creates thermal hot spots affecting performance, or compromises RF performance limiting connectivity — directly impacting battery life, user experience, and feature competitiveness especially for productivity-focused tablets where performance and runtime are critical.

At APTPCB, our manufacturing implements layout optimization achieving performance targets while maximizing battery capacity.

Layout Optimization Implementation

- Zoned Architecture Design: Functional partitioning separating digital, analog, RF, and power sections minimizing cross-coupling while optimizing thermal distribution with medical devices layout discipline.

- Power Distribution Networks: Multi-layer power planes with distributed decoupling maintaining clean power delivery to processors despite large board dimensions.

- High-Speed Interface Management: Length-matched differential pairs for display (eDP, MIPI DSI), storage (UFS), and connectivity (USB) maintaining signal integrity.

- Thermal-Aware Placement: Strategic component positioning utilizing board area for heat spreading while isolating heat-generating components from battery.

- Antenna Integration: Multiple antennas for LTE, WiFi, and GPS positioned for optimal performance while avoiding interference from displays and metal structures.

- Manufacturing Coordination: DFM-optimized layouts facilitating assembly, testing, and integration into tablet chassis through aerospace defense quality standards.

Managing Battery Systems and Extended Runtime

Tablets utilize 5000-10000mAh batteries requiring sophisticated battery management systems monitoring cell voltages, temperatures, and state-of-charge while implementing multi-stage charging, protection circuits, and communication interfaces. Battery challenges include achieving all-day runtime (8-12 hours) supporting productivity workflows, managing charging from diverse power sources (USB-C PD, wireless, proprietary chargers), and ensuring safe operation across temperature ranges. Inadequate battery management causes premature capacity degradation reducing usable lifetime, slow charging frustrating users, or safety incidents from overcharge or overheating — significantly impacting user satisfaction, operational costs, and brand reputation especially for enterprise deployments requiring predictable device lifecycle.

At APTPCB, our manufacturing supports advanced battery management ensuring safety and optimized performance.

Battery Management Implementation

- Multi-Cell Configuration: Series and parallel cell arrangements (2S2P, 3S2P configurations) achieving required voltage and capacity while maintaining size constraints.

- Precision Battery Monitoring: High-resolution voltage and current measurement enabling accurate state-of-charge estimation and remaining runtime prediction.

- Adaptive Charging Algorithms: Multi-stage charging with temperature monitoring optimizing charge speed while maximizing battery longevity.

- Protection Circuit Integration: Hardware overcurrent, overvoltage, and thermal protection preventing safety incidents despite control system failures.

- USB-C Power Delivery: PD negotiation supporting 18-100W charging enabling rapid charging while maintaining compatibility across chargers.

- Battery Authentication: Secure identification of genuine battery packs preventing use of non-compliant third-party batteries through server data center security protocols.

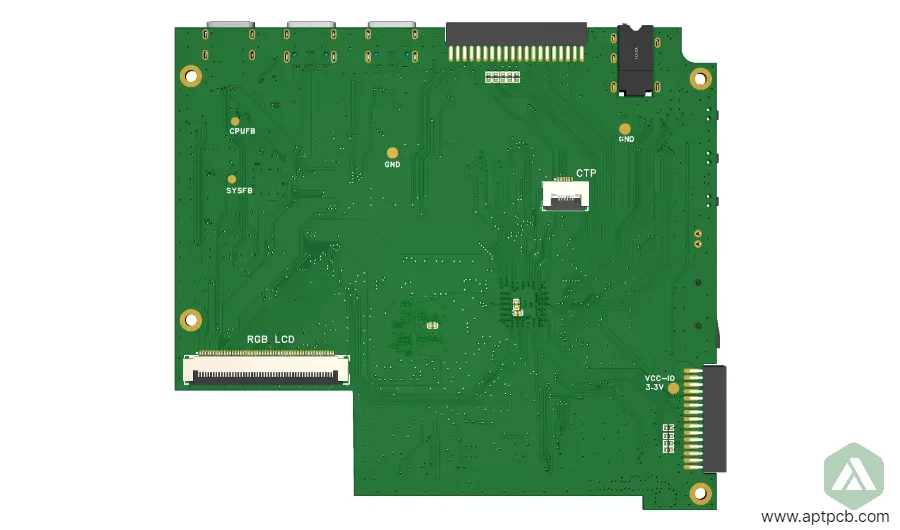

Integrating High-Resolution Display Interfaces

Tablets drive displays ranging from 1920x1200 through 3840x2560 resolution at 60-120Hz requiring high-bandwidth interfaces (eDP, MIPI DSI) delivering several Gbps while maintaining signal integrity across flex cable connections. Display integration challenges include EMI management preventing display noise coupling into wireless systems, precise timing generation maintaining refresh synchronization, and power management for display backlight and touch controllers. Inadequate display implementation causes visual artifacts degrading image quality, electromagnetic interference affecting WiFi or cellular performance, or excessive power consumption reducing battery life — significantly impacting user experience, media consumption quality, and overall device satisfaction especially for content creation and entertainment applications.

At APTPCB, our manufacturing supports high-quality display integration achieving premium visual performance.

Display Interface Implementation

- High-Speed Differential Routing: eDP or MIPI DSI lanes with controlled impedance and length matching supporting 4-8 lanes at 1.62-8.1Gbps enabling 4K displays.

- EMI Shielding Strategies: Grounded shields and spread spectrum clocking reducing display-generated EMI preventing wireless performance degradation.

- Backlight Driver Integration: Precision LED drivers with dimming control supporting adaptive brightness while maintaining color accuracy and efficiency.

- Touch Controller Interface: I2C or SPI communication with touch digitizers supporting multi-touch, stylus input, and palm rejection algorithms.

- Display Power Sequencing: Coordinated voltage rail activation preventing display damage and ensuring proper initialization during power-on.

- Validation Testing: VESA compliance testing and EMI characterization ensuring display quality and electromagnetic compatibility through security equipment standards.

Providing Enterprise and Rugged Platform Support

Enterprise tablets require enhanced security (TPM, secure boot), device management (MDM integration), and extended support lifecycles (5-7 years) while rugged variants demand IP65-68 protection, MIL-STD-810 compliance, and hot-swappable batteries. Enterprise and rugged requirements influence component selection, sealing strategies, connector choices, and documentation practices supporting specialized deployments. Inadequate enterprise features limit corporate adoption, insufficient ruggedness causes field failures in harsh environments, or poor MDM integration complicates fleet management — significantly impacting total cost of ownership, operational efficiency, and suitability for vertical markets including field service, healthcare, manufacturing, and public safety.

At APTPCB, we support enterprise and rugged tablet manufacturing with specialized processes.

Enterprise and Rugged Implementation

Enterprise Features

- Security module integration (TPM 2.0) supporting enterprise encryption and authentication requirements.

- Enhanced I/O options (Ethernet, serial, additional USB) supporting specialized peripherals and legacy equipment connectivity.

- Extended temperature range components (-20 to +60°C) supporting warehouse, outdoor, and vehicle-mounted applications.

- Long-term component availability ensuring devices remain supportable throughout 5-7 year enterprise deployment cycles.

Rugged Construction

- Conformal coating and sealing achieving IP65-68 protection against dust, water, and chemical exposure.

- Reinforced mounting and shock isolation surviving MIL-STD-810 drop and vibration testing.

- Extended temperature operation (-30 to +70°C) supporting extreme environments from freezers to direct sunlight.

- Hot-swappable battery systems enabling continuous operation during battery replacement for 24/7 field use.

Supporting Educational and Budget Tablet Manufacturing

Educational tablets require aggressive cost optimization while maintaining adequate performance, durability, and manageability supporting classroom deployments. Manufacturing challenges include achieving <$200 device costs, implementing kid-friendly durability features, and supporting volume production for institutional purchasing. Inadequate cost optimization prevents educational market access, insufficient durability causes high breakage rates increasing total cost, or poor manageability complicates classroom IT support — significantly impacting adoption in education markets where budget constraints are severe and deployments number in thousands or millions of devices.

At APTPCB, we support cost-optimized tablet manufacturing enabling educational market access.

Cost Optimization Strategies

- Mainstream Component Selection: Balanced performance processors and memory configurations meeting educational workloads while achieving cost targets.

- Simplified PCB Construction: 6-8 layer stackups versus 10-14 layers in flagship devices reducing material costs while maintaining reliability.

- Strategic Feature Reduction: Eliminating high-cost features (cellular, stylus, fingerprint) focusing on essential functionality for educational use.

- Volume Manufacturing Optimization: High-volume assembly processes achieving economies of scale supporting large institutional orders.

- Extended Lifecycle Support: Long production runs with stable BOMs minimizing engineering changes and supporting multi-year educational contracts.

Through cost-conscious design, efficient manufacturing, and volume production capabilities, APTPCB enables tablet manufacturers serving education markets achieving cost targets while maintaining adequate performance and reliability for classroom environments.