Contents

- The Context: What Makes Vrf Control PCB Challenging

- The Core Technologies (What Actually Makes It Work)

- Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

- Comparison: Common Options and What You Gain / Lose

- Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

- The Future: Where This Is Going (Materials, Integration, Ai/automation)

- Request a Quote / DFM Review for Vrf Control PCB (What to Send)

- Conclusion

Highlights

- Mixed-Signal Complexity: Successfully isolating high-voltage inverter drives from sensitive sensor inputs on the same or adjacent boards.

- Thermal Management: Handling heat dissipation from IGBTs and IPMs using heavy copper or metal core strategies.

- Environmental Durability: The necessity of robust surface finishes and conformal coatings to withstand humidity and temperature cycling.

- Manufacturing Precision: How layer stack-up and impedance control affect communication reliability between indoor and outdoor units.

The Context: What Makes Vrf Control PCB Challenging

The fundamental challenge in designing and manufacturing a VRF Control PCB is the coexistence of extremes. On one side of the system, the board must handle high-current power switching to drive the variable speed compressor. This involves rapid switching frequencies that generate significant heat and electromagnetic interference (EMI). On the other side, the same control system must read minute voltage changes from temperature sensors and pressure transducers to adjust refrigerant flow with high precision.

This duality creates a hostile environment for the printed circuit board. If the ground planes are not designed correctly, the noise from the inverter drive can corrupt the data from the sensors, leading to inefficient operation or system faults. Furthermore, these boards are often installed in outdoor units on rooftops, exposing them to wide temperature swings, humidity, and vibration. Manufacturers like APTPCB (APTPCB PCB Factory) often see designs that fail not because of component failure, but because the PCB substrate or vias could not withstand the thermal expansion and contraction cycles over time.

Additionally, the supply chain pressure for HVAC components demands a balance between cost and robustness. Over-engineering the board with excessive layers adds unnecessary cost, while under-specifying the copper weight or laminate Tg (Glass Transition Temperature) risks field failures. The goal is a balanced stack-up that provides thermal headroom and electrical isolation without inflating the BOM cost.

The Core Technologies (What Actually Makes It Work)

The functionality of a VRF Control PCB relies on several distinct technology blocks working in unison. Understanding these helps in specifying the right fabrication requirements.

- Inverter Drive Circuitry: This is the power heart of the system. It typically utilizes Insulated Gate Bipolar Transistors (IGBTs) or Intelligent Power Modules (IPMs). The PCB here requires Heavy Copper PCB traces to carry high currents with minimal resistive heating. The layout must minimize loop inductance to protect the switches from voltage spikes.

- Microcontroller (MCU) & Logic: The brain of the board runs complex algorithms to calculate the required refrigerant load. This section requires clean power rails and careful routing. High-density interconnect (HDI) techniques are sometimes employed if the MCU package is a fine-pitch BGA, though standard multilayer designs are more common for cost reasons.

- Communication Interfaces: VRF systems rely on continuous communication between the outdoor unit and multiple indoor units. RS-485 is the standard physical layer, requiring differential pair routing. Impedance control is critical here to prevent signal reflections over long cable runs.

- Sensor Interfaces: Inputs for thermistors, pressure sensors, and flow meters are highly sensitive to noise. Good designs utilize separate analog ground planes or "star ground" topologies to keep inverter noise away from these signals.

Ecosystem View: Related Boards / Interfaces / Manufacturing Steps

A VRF Control PCB rarely operates in isolation. It is part of a larger electronic ecosystem within the HVAC unit.

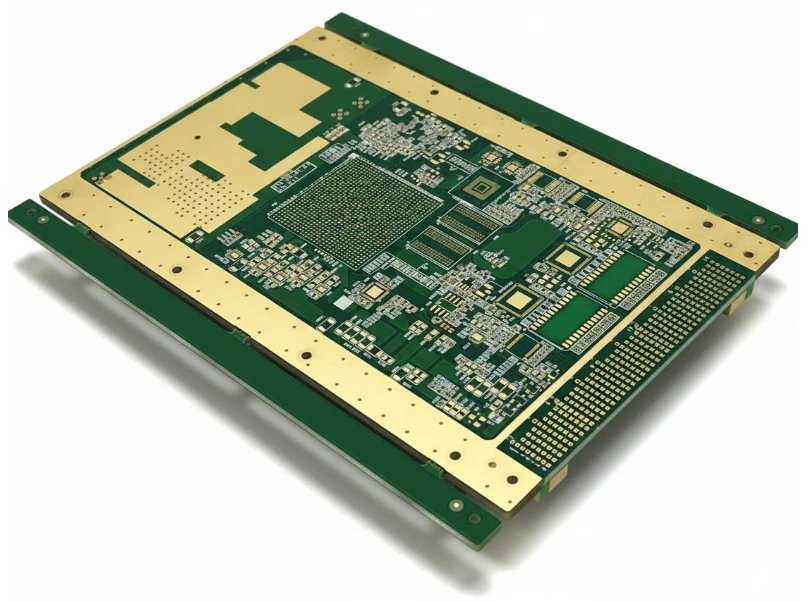

Interconnected Modules: Often, the control system is split. A main control board handles logic and communication, while a separate power board (or inverter board) handles the high-voltage switching. These boards connect via board-to-board connectors or heavy-gauge wire harnesses. The reliability of the main control PCB depends heavily on how well it interfaces with these peripherals. For instance, if the Industrial Control PCB design does not account for the inrush current from the power board, traces can fuse or delaminate.

Assembly and Protection: Once the bare board is fabricated, the assembly process (PCBA) introduces its own variables. Large capacitors and heavy inductors used in the power filters require robust solder joints, often necessitating selective soldering or additional mechanical support. Because these boards live outdoors, PCB Conformal Coating is not optional—it is a critical manufacturing step to prevent dendritic growth and corrosion caused by condensation.

Thermal Interface: For boards carrying power modules, the interface to the heatsink is vital. This might involve thermal vias stitched through the PCB to a bottom-side pad, or the use of Metal Core PCB (MCPCB) technology where the dielectric is thermally conductive, transferring heat directly to an aluminum base.

Comparison: Common Options and What You Gain / Lose

Engineers often face trade-offs when specifying materials and structures for VRF controllers. The choice between standard FR4 and specialized materials, or between standard copper and heavy copper, dictates the board's thermal ceiling and longevity.

Below is a decision matrix illustrating how specific technical choices translate into practical outcomes for the final product.

Decision Matrix: Technical Choice → Practical Outcome

| Technical choice | Direct impact |

|---|---|

| Standard FR4 vs. High Tg FR4 | High Tg (170°C+) prevents pad lifting and via cracking during high-temp operation, essential for outdoor units. |

| 1oz Copper vs. 3oz+ Heavy Copper | Heavy copper handles higher surge currents and spreads heat better, but requires wider spacing (design rule changes). |

| HASL vs. ENIG Surface Finish | ENIG offers a flatter surface for fine-pitch components (MCUs) and better corrosion resistance than HASL. |

| Discrete Components vs. IPM | Intelligent Power Modules simplify layout and save space but concentrate heat in one spot, demanding better thermal management. |

Reliability & Performance Pillars (Signal / Power / Thermal / Process Control)

To ensure a VRF Control PCB survives its warranty period, four pillars of reliability must be addressed during the design and fabrication phases.

1. Thermal Endurance The board will cycle between freezing winter temperatures and blistering summer heat, plus the self-heating of power components. Using a High Tg PCB material ensures the Z-axis expansion of the board does not rip apart the copper plating inside the via holes. Thermal simulation should verify that no junction temperature exceeds safe limits under maximum load.

2. Power Integrity The inverter section draws current in pulses. If the power planes are too thin or the decoupling capacitors are too far away, the voltage rail will sag, potentially resetting the microcontroller. Wide power planes and low-inductance layout strategies are non-negotiable.

3. Signal Integrity (EMI/EMC) VRF systems are notorious electrical noise generators. The PCB must pass stringent EMC testing. This involves keeping high-speed switching nodes compact to minimize their antenna effect. Ground planes should be continuous; splitting a ground plane under a high-speed trace is a common recipe for EMI failure.

4. Process Control Fabrication quality matters. The thickness of the hole wall plating (typically 20-25µm minimum) is critical for long-term reliability. APTPCB emphasizes that for industrial controls, strict adherence to IPC Class 2 or Class 3 standards for plating thickness and solder mask adhesion is vital to prevent latent failures.

| Feature | Acceptance Criteria (Typical) |

|---|---|

| Hole Wall Copper | Average 25µm, min 20µm (IPC Class 3 recommended for harsh environments) |

| Solder Mask | High-temp resistant, no peeling after thermal stress |

| Ionic Contamination | < 1.56 µg/cm² NaCl equivalent (to prevent electrochemical migration) |

| Bow and Twist | < 0.75% (critical for automated assembly of large panels) |

The Future: Where This Is Going (Materials, Integration, Ai/automation)

The VRF industry is moving toward higher efficiency and smarter diagnostics. This evolution directly impacts PCB requirements. We are seeing a shift from silicon-based IGBTs to Wide Bandgap (WBG) materials like Silicon Carbide (SiC) and Gallium Nitride (GaN), which switch faster and run hotter. This pushes the thermal requirements of the PCB even further.

Simultaneously, the "intelligence" of the board is increasing. Future controllers will likely integrate edge AI to predict compressor failures before they happen, requiring more powerful processors and higher-speed memory interfaces on the same board.

5-Year Performance Trajectory (Illustrative)

| Performance metric | Today (typical) | 5-year direction | Why it matters |

|---|---|---|---|

| Switching Frequency | 15-20 kHz | 50-100 kHz (SiC/GaN) | Allows for smaller passive components (inductors/capacitors), reducing board size. |

| Integration Level | Separate Power & Logic | Single Mixed-Signal Board | Reduces cabling and assembly costs but increases crosstalk challenges. |

| Data Connectivity | RS-485 / Modbus | Industrial Ethernet / Wireless | Enables real-time cloud analytics and predictive maintenance (Digital Twin). |

Request a Quote / DFM Review for Vrf Control PCB (What to Send)

When engaging a manufacturer for VRF Control PCBs, clarity in the documentation package is essential to avoid delays. Because these boards often combine high power and fine pitch, a DFM Guidelines review is highly recommended before mass production. Ensure your RFQ package includes the following details to get an accurate quote and technical assessment:

- Gerber Files: RS-274X format, including all copper layers, solder mask, and silkscreen.

- Stack-up Diagram: Explicitly state dielectric thickness and copper weights (e.g., "Outer 1oz, Inner 2oz").

- Material Specs: Specify Tg requirement (e.g., Tg170) and CTI (Comparative Tracking Index) if high voltage is present.

- Surface Finish: ENIG is preferred for reliability; specify thickness if critical.

- Drill Chart: Distinguish between plated and non-plated holes.

- Panelization: If you have specific array requirements for your assembly line.

- Special Requirements: Note any impedance control (e.g., 100Ω differential for RS-485) or specific conformal coating areas.

- Volume & Lead Time: Prototype quantity vs. production EAU (Estimated Annual Usage).

Conclusion

The VRF Control PCB is more than just a carrier for components; it is a critical structural element that defines the efficiency and lifespan of modern HVAC systems. Balancing the thermal demands of power inverters with the signal integrity needs of sensitive logic requires a holistic approach to design and materials.

As energy regulations tighten and systems become smarter, the PCB must evolve to handle higher voltages and faster data streams. By partnering with an experienced fabricator like APTPCB early in the design phase, engineers can navigate these trade-offs effectively, ensuring that the final product delivers reliable comfort for years to come.