Wearable technology PCB assemblies integrate sensors, processors, wireless connectivity, and power management into ultra-compact form factors measuring just 10-30mm requiring rigid-flex construction, biocompatible materials, and sub-50mW power consumption across smartwatches, fitness bands, medical monitors, AR glasses, and health tracking devices demanding reliable operation through thousands of wear cycles, temperature extremes (-20 to +60°C), moisture exposure, and mechanical stress while maintaining FDA compliance for medical applications or consumer safety certifications supporting 2-5 year product lifecycles.

At APTPCB, we deliver specialized wearable PCB assembly services implementing miniaturized component placement, flexible circuit integration, and validated biocompatibility testing with turnkey assembly capabilities. Our expertise supports fitness trackers requiring <20mAh daily power consumption through medical wearables demanding Class II device compliance with comprehensive validation ensuring reliability across body-worn environments.

Achieving Ultra-Miniature Component Integration

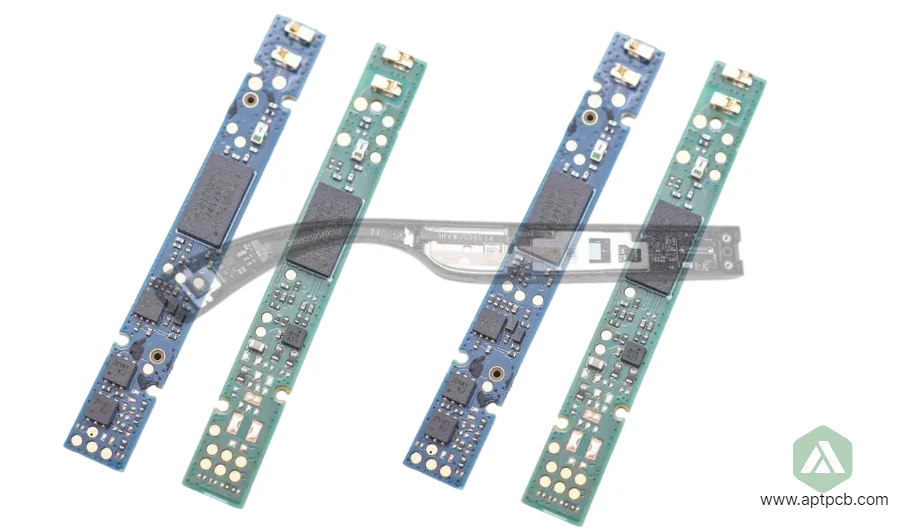

Wearable devices demand extreme miniaturization fitting complete systems (CPU, memory, sensors, wireless, battery management) into volumes <1cm³ while maintaining manufacturing yield and long-term reliability. Component packages measuring 0.4x0.2mm (01005 passives), 0.5mm pitch BGAs, and wafer-level chip-scale packages create assembly challenges where placement accuracy tolerances shrink to ±15μm and solder joint inspection requires high-magnification X-ray systems. Inadequate miniaturization forces design compromises reducing battery capacity and runtime, limits sensor integration affecting feature sets, or increases product thickness reducing comfort and aesthetics — directly impacting market competitiveness, user acceptance, and commercial success in consumer wearables markets.

At APTPCB, our assembly services implement advanced miniaturization techniques achieving industry-leading component density and reliability.

Key Miniaturization Implementation Techniques

- Ultra-Fine-Pitch Component Assembly: Precision placement equipment achieving ±15μm accuracy handling 0201/01005 passives, 0.35mm pitch BGAs, and wafer-level CSPs with testing quality validation ensuring reliable joints.

- Package-on-Package Stacking: PoP technology vertically stacking memory on processors reducing footprint 40-60% while maintaining electrical performance and thermal management.

- System-in-Package Integration: Multi-die SiP modules combining processors, memory, RF, and power management in single packages reducing assembly complexity and board area.

- Anisotropic Conductive Film Bonding: ACF attachment of display drivers and flex circuits enabling ultra-fine-pitch connections without traditional solder processes.

- Laser Direct Structuring: LDS technology creating 3D circuit traces on molded plastic substrates enabling integration of antennas and circuits on structural components.

- Advanced PCB Construction: HDI PCBs with 50-75μm traces, microvias <100μm, and stacked vias enabling high routing density in minimal layers through functional testing validation.

Validated Miniature Assembly

By implementing state-of-the-art assembly equipment, advanced packaging technologies, and comprehensive process validation supported by quality management systems, APTPCB enables wearable manufacturers achieving extreme miniaturization supporting thinner products, longer battery life, and enhanced feature integration across smartwatch, fitness tracker, and medical wearable applications.

Managing Power Consumption in Battery-Constrained Designs

Wearable devices operate from tiny batteries (<300mAh) requiring complete systems consuming <50mW during active operation and <10μW during sleep modes achieving multi-day battery life meeting user expectations. Power optimization requires sophisticated system architecture combining ultra-low-power microcontrollers, efficient power management, aggressive duty cycling, and optimized firmware minimizing active time while maintaining responsive user experience. Inadequate power management causes frequent charging cycles frustrating users, limits sensor sampling rates reducing data quality, or forces larger batteries increasing size and weight — significantly impacting user satisfaction, product reviews, and market adoption especially for always-on health monitoring applications.

At APTPCB, our manufacturing supports ultra-low-power designs implementing validated power optimization strategies.

Power Optimization Implementation Techniques

- Ultra-Low-Power Component Selection: ARM Cortex-M0+ microcontrollers consuming <100μA/MHz, low-quiescent-current regulators (<1μA), and power-gated subsystems minimizing standby power with quality system component qualification.

- Dynamic Voltage and Frequency Scaling: Adaptive operation adjusting processor speed and supply voltage based on computational requirements reducing power 50-80% during light workloads.

- Power Domain Management: Independent power rails for sensors, wireless, display enabling selective activation powering only required subsystems for specific functions.

- Duty-Cycled Sensor Operation: Periodic sensor sampling (heart rate every 5s, motion at 50Hz) rather than continuous monitoring reducing average power consumption while maintaining data quality.

- Efficient Wireless Protocols: BLE 5.0 with coded PHY extending range while reducing power, or proprietary low-power protocols optimized for wearable applications.

- Power Measurement Validation: Comprehensive current profiling across operating modes validating power budgets and identifying optimization opportunities through NPI assembly characterization.

Extended Battery Life Achievement

Through comprehensive power optimization strategies, validated component selection, and thorough power characterization supported by manufacturing expertise, APTPCB enables wearable designs achieving multi-day battery life supporting continuous health monitoring, activity tracking, and smart notifications meeting user expectations across consumer and medical wearable applications.

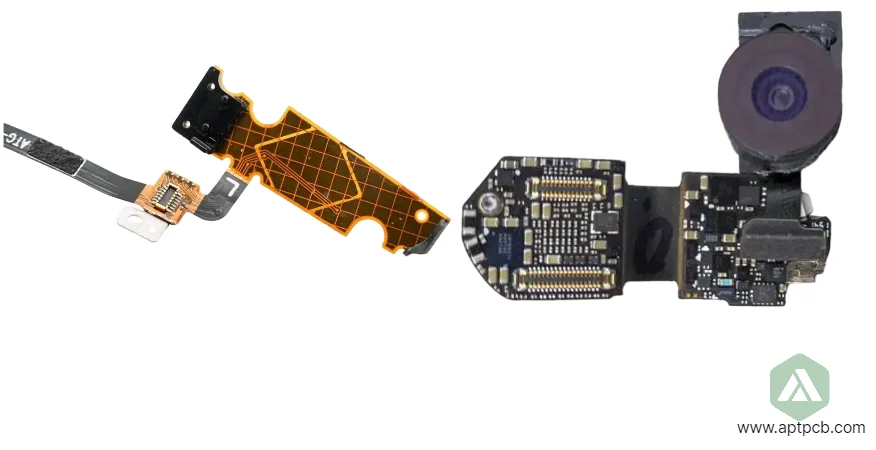

Implementing Flexible and Rigid-Flex Circuit Integration

Wearable products require conformable electronics wrapping around wrists, arms, or heads using flexible or rigid-flex PCB construction accommodating product curvature while surviving repeated flexing from user motion. Design and manufacturing challenges include maintaining electrical integrity during dynamic flexing, managing stress concentration at rigid-flex transitions, and achieving reliable interconnections withstanding millions of flex cycles. Inadequate flex design causes interconnect failures from flex fatigue, delamination at material interfaces, or electrical opens from excessive bending stress — resulting in premature product failures, warranty returns, and brand damage especially for products experiencing daily wear and removal cycles.

At APTPCB, our manufacturing implements validated rigid-flex construction ensuring mechanical reliability across product lifecycles.

Rigid-Flex Implementation Techniques

- Optimized Stackup Design: Strategic layer transitions between rigid and flex sections using tapered transitions and staggered copper features minimizing stress concentration with mass production process validation.

- Flexible Material Selection: Polyimide flex circuits with rolled-annealed copper foils achieving >10 million flex cycles in dynamic applications versus standard electrodeposited copper.

- Bend Radius Management: Component keepout zones and trace routing perpendicular to bend axis maintaining minimum 10:1 bend radius-to-thickness ratios preventing copper fatigue.

- Adhesiveless Construction: Bondply-free stackups reducing thickness and improving flexibility enabling tighter bend radii while maintaining reliability.

- Stiffener Integration: Selective stiffeners supporting connectors and components while maintaining overall flexibility balancing mechanical requirements with product form factor.

- Flex Life Testing: Mechanical cycling validation (>1 million cycles) confirming reliability across expected product lifetime through component sourcing of qualified materials.

Reliable Flexible Electronics

By implementing validated rigid-flex design practices, qualified material selection, and comprehensive mechanical testing coordinated with manufacturing processes, APTPCB delivers wearable PCBs achieving mechanical reliability specifications supporting products experiencing continuous flexing, daily handling, and multi-year operational lifetimes.

Ensuring Biocompatibility and Skin Safety

Wearable devices maintaining continuous skin contact require biocompatible materials and protective coatings preventing skin irritation, allergic reactions, or toxic exposure. Medical wearables demand ISO 10993 biocompatibility testing validating cytotoxicity, sensitization, and irritation while consumer products require nickel release testing and dermatological assessments. Inadequate biocompatibility causes skin rashes affecting user comfort, allergic reactions limiting market segments, or regulatory compliance failures preventing product launch — significantly impacting market access, customer satisfaction, and brand reputation especially for continuous-wear health monitoring devices.

At APTPCB, our manufacturing implements biocompatible processes and materials supporting body-worn applications.

Biocompatibility Implementation Techniques

- Material Selection Standards: Biocompatible PCB laminates, lead-free HASL or ENIG surface finishes, and medical-grade conformal coatings meeting ISO 10993 requirements with PCB conformal coating application expertise.

- Nickel Barrier Integration: ENIG surface finish with adequate gold thickness (>3μin) preventing nickel exposure or specialized coatings encapsulating exposed conductors.

- Comprehensive Coating Application: Parylene or medical-grade urethane coatings providing complete circuit encapsulation preventing direct skin contact with electronics.

- Hypoallergenic Component Selection: Avoiding known allergens in adhesives, potting materials, and structural components supporting users with sensitive skin.

- Biocompatibility Testing: ISO 10993-5 (cytotoxicity), -10 (sensitization), and -23 (irritation) testing validating material safety before market introduction.

- Manufacturing Cleanliness: Controlled assembly environments preventing contamination with oils, residues, or particulates affecting biocompatibility through special PCB manufacturing processes.

Safe Body-Worn Electronics

Through biocompatible material selection, validated coating processes, and comprehensive testing protocols supported by quality systems, APTPCB enables wearable manufacturers deploying products meeting safety requirements for continuous skin contact supporting medical device compliance and consumer safety across health monitoring, fitness tracking, and medical wearable applications.

Managing Sensor Integration and Signal Quality

Wearable devices integrate diverse sensors (heart rate, SpO2, accelerometer, gyroscope, temperature, ECG) requiring precise analog signal conditioning, noise filtering, and calibration achieving medical-grade accuracy despite challenging measurement conditions on moving users. Signal quality challenges include motion artifacts from user movement, ambient light interference in optical sensors, and electromagnetic interference from nearby devices affecting measurements. Inadequate sensor implementation causes inaccurate health metrics eroding user trust, false alarms causing notification fatigue, or regulatory compliance failures preventing medical device clearance — significantly impacting product credibility, clinical utility, and commercial success especially for applications supporting health decisions.

At APTPCB, our assembly supports high-quality sensor integration achieving clinical measurement accuracy.

Sensor Integration Implementation Techniques

- Precision Analog Front-End Design: Low-noise amplifiers, high-resolution ADCs (16-24 bit), and anti-aliasing filters achieving signal-to-noise ratios >60dB supporting accurate biometric measurements.

- Optical Sensor Optimization: Precise LED drive circuits and photodiode signal conditioning with ambient light rejection enabling accurate PPG measurements for heart rate and SpO2.

- Motion Sensor Calibration: Factory calibration of accelerometer and gyroscope offset, sensitivity, and cross-axis errors achieving ±2% accuracy supporting activity recognition algorithms.

- Electromagnetic Shielding: Grounded shields over sensitive analog circuits and filtered power supplies preventing interference from wireless radios or external sources.

- Impedance-Matched ECG Inputs: High input impedance (>10MΩ) biopotential amplifiers with proper grounding minimizing motion artifacts in ECG measurements.

- Validation Testing: Clinical correlation studies comparing wearable measurements against gold-standard medical equipment validating accuracy specifications across user populations.

Clinical-Grade Measurement Quality

Through precision analog design, validated calibration procedures, and comprehensive accuracy testing coordinated with manufacturing processes, APTPCB enables wearable devices achieving clinical-grade measurement accuracy supporting FDA clearance, CE marking, and commercial medical applications across continuous health monitoring, diagnostic support, and clinical research platforms.

Supporting Diverse Wearable Form Factors and Applications

Wearable electronics span diverse applications from consumer fitness bands requiring cost optimization through medical monitors demanding regulatory compliance to AR/VR headsets requiring high-performance processing and displays. Form factor requirements range from coin-sized earbuds through watch-sized wristbands to glasses-mounted displays each presenting unique design challenges in thermal management, mechanical integration, antenna design, and user interface implementation.

At APTPCB, we provide flexible manufacturing supporting diverse wearable applications and form factors.

Application-Specific Manufacturing Support

Consumer Fitness and Smartwatches

- Cost-optimized assembly achieving competitive consumer pricing while maintaining quality and reliability standards supporting mass-market products.

- Stylish industrial design integration accommodating curved displays, touch interfaces, and premium materials meeting consumer aesthetic expectations.

- Multi-day battery life optimization through power management and efficient component selection supporting typical usage patterns.

- Splash and sweat resistance (IP67/IP68) protecting electronics during exercise and daily activities through validated environmental protection.

Medical and Clinical Wearables

- FDA/CE regulatory compliance support including design controls, risk management, and documentation supporting Class II medical device clearance.

- Clinical accuracy validation achieving standards for heart rate (±5bpm), SpO2 (±2%), and blood pressure measurements.

- Medical-grade biocompatibility and long-term reliability supporting continuous patient monitoring applications.

- Secure data handling and HIPAA compliance protecting patient health information in connected health applications.

AR/VR and Advanced Wearables

- High-performance processing and thermal management supporting real-time graphics rendering and computer vision algorithms.

- Multiple high-resolution displays and camera integration enabling immersive experiences and environmental understanding.

- Advanced sensor fusion combining IMU, cameras, and depth sensors supporting precise tracking and spatial mapping.

- Comfortable ergonomics despite complex electronics enabling extended wear sessions for gaming, training, or productivity applications.

Through application-optimized designs, flexible manufacturing capabilities, and comprehensive regulatory support, APTPCB enables wearable manufacturers deploying successful products across consumer fitness, medical monitoring, industrial safety, and emerging AR/VR markets supporting diverse user needs and regulatory requirements worldwide.