Wireless charger PCB designs implement Qi-compliant inductive power transfer delivering 5-15W through magnetic coupling requiring precision coil design, foreign object detection, thermal management, and EMI control across smartphone charging pads, automotive wireless charging, furniture-integrated chargers, and multi-device platforms demanding >70% efficiency, Qi certification compliance, and safe operation detecting metallic objects preventing overheating supporting millions of charge cycles over 5-10 year product lifecycles.

At APTPCB, we deliver specialized wireless charging design services implementing Qi-certified architectures, optimized coil layouts, and validated safety features with component sourcing of certified Qi ICs supporting 5W basic through 15W extended power profiles.

Achieving Qi Certification and Standards Compliance

Qi wireless charging standard mandates strict electrical specifications, communication protocols, foreign object detection, and safety features requiring validated designs passing WPC certification testing. Certification challenges include maintaining precise operating frequency (87-205kHz for BPP/EPP), implementing compliant communication (ASK modulation for negotiation), and validating FOD sensitivity across diverse object types. Inadequate compliance implementation prevents Qi certification blocking market access, causes interoperability issues with smartphones, or creates safety risks from undetected foreign objects — significantly impacting product launch, user experience, and liability exposure especially for automotive and public charging applications where safety is critical.

At APTPCB, our designs implement Qi-compliant architectures ensuring certification and interoperability.

Qi Compliance Implementation

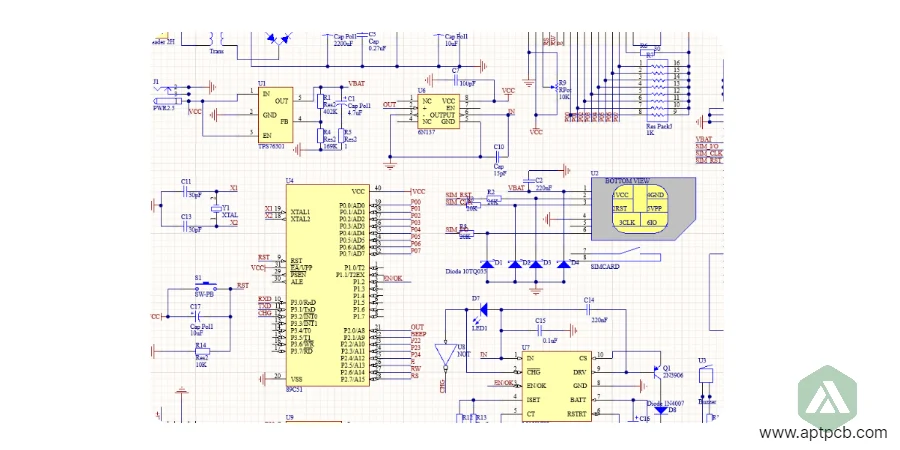

- Certified Controller Selection: WPC-certified transmitter ICs (IDT, NXP, TI) implementing compliant communication, power control, and FOD with PCB conformal coating protection.

- Frequency Control Precision: Crystal oscillators and PLL configurations maintaining operating frequency within ±0.5% tolerance ensuring reliable power transfer.

- Communication Protocol Implementation: ASK demodulation receiving power control packets from receiver devices adjusting transmitter power accordingly.

- Power Profile Support: 5W Basic Power Profile (BPP) and 15W Extended Power Profile (EPP) supporting diverse smartphone capabilities.

- Certification Testing: WPC test lab validation including electrical characterization, FOD testing, and interoperability validation with certified receivers.

Implementing Foreign Object Detection and Safety

Foreign object detection prevents heating of metallic objects (coins, keys, jewelry) placed on charging surface potentially causing burns or damage requiring sensitive detection algorithms, calibrated coil Q-factor measurement, and rapid power shutdown. FOD challenges include detecting small objects <5mm, distinguishing legitimate power losses from foreign objects, and maintaining sensitivity despite aging or environmental variations. Inadequate FOD implementation causes safety incidents from overheating objects, false positives interrupting charging frustrating users, or insufficient sensitivity failing to detect dangerous objects — significantly impacting user safety, regulatory compliance, and product liability especially for public and automotive charging where object introduction is unpredictable.

At APTPCB, our designs implement validated FOD ensuring user safety and Qi compliance.

FOD Implementation Techniques

- Q-Factor Measurement: Real-time coil quality factor monitoring detecting impedance changes from metallic objects versus legitimate receivers with special PCB manufacturing precision.

- Power Loss Method: Comparing transmitted and received power identifying excessive losses indicating foreign object presence causing heating.

- Temperature Monitoring: NTC thermistors on charging surface detecting abnormal heating triggering rapid shutdown before damage occurs.

- Adaptive Thresholds: Learning algorithms compensating for environmental variations and aging maintaining FOD sensitivity throughout product life.

- Rapid Power Cutoff: <100ms response time from detection to power shutdown preventing significant heating of foreign objects.

Optimizing Efficiency and Thermal Management

Wireless charging efficiency typically reaches 70-80% generating 3-6W heat in 15W chargers requiring effective thermal management preventing overheating causing user discomfort, plastic deformation, or premature component failure. Thermal challenges include concentrating heat in small charging pads, managing heat near battery during simultaneous use and charge, and maintaining efficiency despite thermal throttling. Inadequate thermal design causes hot surfaces uncomfortable to touch, reduced charging power from thermal limiting, or reliability issues from sustained elevated temperatures — significantly impacting user experience, charging performance, and long-term reliability especially for automotive applications in direct sunlight or consumer chargers supporting fast charging.

At APTPCB, our designs implement thermal strategies maintaining safe temperatures while maximizing charging power.

Thermal and Efficiency Optimization

- Low-Loss Component Selection: Low-resistance MOSFETs, low-DCR inductors, and efficient rectifiers minimizing losses improving overall efficiency 3-5%.

- Coil Design Optimization: Litz wire construction and optimized winding patterns minimizing AC resistance reducing coil losses at high frequencies.

- Thermal Interface Design: Precision gap control between coils and housing maximizing conductive heat transfer to chassis or heat sinks.

- Active Cooling Integration: Optional fan-assisted cooling in high-power automotive applications maintaining power delivery despite ambient heat.

- Temperature-Based Power Management: Dynamic power limiting based on thermal sensor feedback preventing overheating while maximizing charging speed.

Supporting Multi-Device and Automotive Applications

Multi-device chargers accommodate phones, watches, and earbuds simultaneously requiring multiple transmitter coils, coordinated power management, and position-free charging. Automotive wireless charging faces extreme temperatures (-40 to +85°C), vibration, and integration with vehicle electronics requiring ruggedized construction and automotive-grade components. Application-specific requirements influence coil layout, housing integration, and certification needs supporting diverse markets. Inadequate application optimization limits market opportunity, insufficient ruggedization causes automotive failures, or poor multi-device coordination frustrates users — significantly impacting market suitability, user satisfaction, and product differentiation.

At APTPCB, we support diverse wireless charging applications with specialized design expertise.

Application-Specific Design Support

Multi-Device Charging Platforms

- Overlapping coil arrays enabling position-free charging across large surfaces supporting simultaneous device charging.

- Intelligent coil activation detecting device presence and activating only required coils minimizing power consumption.

- Power allocation management distributing available power across multiple devices ensuring adequate charging for each.

Automotive Wireless Charging

- Automotive-grade components (-40 to +125°C) surviving extreme temperature variations in vehicle cabins.

- Vibration and shock resistance meeting automotive environmental standards.

- Vehicle integration supporting CAN communication and dashboard status display.

- Safety features preventing charging with metallic phone cases or improper placement.

Through application-optimized designs and comprehensive validation coordinated with automotive electronics standards, APTPCB enables wireless charging manufacturers serving consumer, commercial, and automotive markets.