Motor driver PCBs enable precise motion control across robotics, factory automation, HVAC systems, consumer appliances, and industrial machinery implementing three-phase inverters for BLDC motors, stepper motor control, servo drives, and DC motor controllers handling currents from 1A (small actuators) through 100A+ (industrial drives) with switching frequencies 4-50kHz requiring robust thermal management, encoder interface integration, and protection circuits ensuring reliable operation through millions of motor start-stop cycles.

At APTPCB, we manufacture motor driver PCBs with industrial control expertise implementing optimized power stages, gate drive circuits, and control interfaces. Our capabilities support brushless DC, stepper, servo, and DC motors across voltage ranges from 12V consumer through 800V industrial drives with comprehensive functional testing validating motor control performance.

Implementing High-Current Three-Phase Power Stages

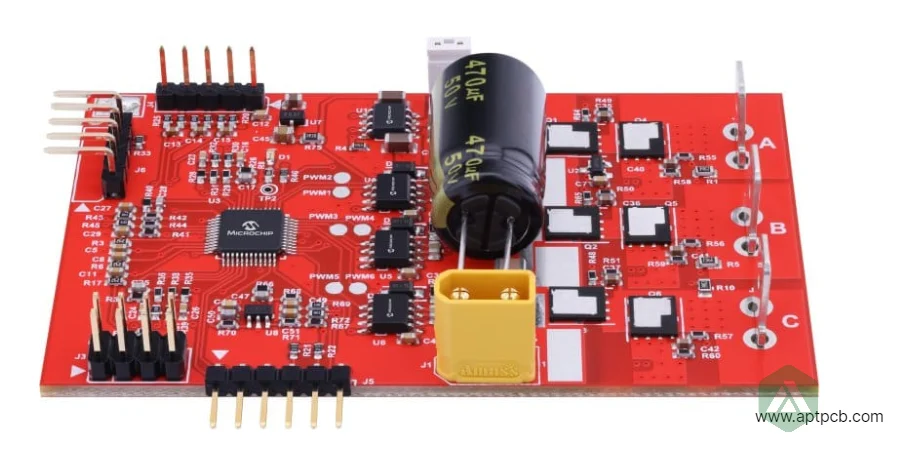

BLDC motor drivers require three-phase inverter bridges delivering multi-ampere currents to motor windings with precise timing control achieving efficient commutation, smooth torque delivery, and minimal acoustic noise. Power stage design must handle continuous and peak currents, manage thermal dissipation, and provide protection against overcurrent, overvoltage, and shoot-through failures.

At APTPCB, our manufacturing implements robust power stages supporting reliable motor operation.

Key Power Stage Requirements

Power Semiconductor Integration

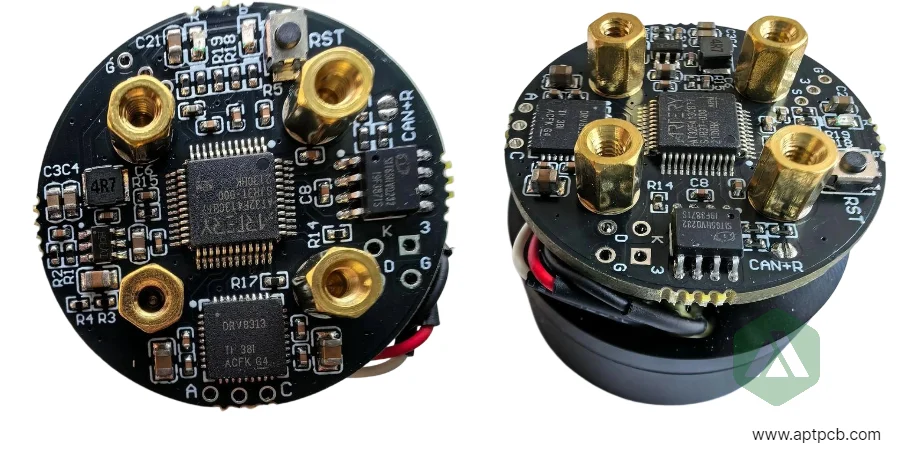

- MOSFET or IGBT selection based on voltage and current requirements with drone UAV applications requiring compact high-performance designs

- Six-switch three-phase bridge configuration enabling bidirectional current control

- Parallel device mounting for high-current applications distributing thermal loads

- Gate drive optimization achieving fast switching while preventing shoot-through

- Current sensing using shunt resistors or Hall sensors providing feedback

- Thermal interface design maintaining junction temperatures within specifications

PCB Layout and Thermal

- Heavy copper construction (3-6oz) handling continuous motor phase currents

- Wide traces in power distribution minimizing resistive losses and voltage drops

- Thermal via arrays transferring heat from semiconductors to heat sinks

- Component placement optimizing thermal distribution and airflow patterns

- Multi-layer stackup with power planes distributing current efficiently

- Thermal simulation validating temperatures across operating conditions

Integrating Encoder and Hall Sensor Interfaces

Motor position feedback using encoders, Hall sensors, or resolvers enables closed-loop control providing precise speed regulation, position control, and torque management. Interface circuits must provide proper sensor excitation, signal conditioning, and noise filtering ensuring accurate position measurement despite electromagnetic interference from motor switching and industrial environments.

APTPCB manufactures motor drivers with validated sensor interface circuits.

Key Interface Implementation

Hall Sensor Integration

- 5V or 12V sensor excitation with current limiting protecting sensors

- Digital input conditioning with Schmitt triggers providing noise immunity

- Commutation logic generating proper switching sequences from Hall states

- Sensor fault detection identifying open or shorted Hall connections

- PCB layout separating sensor circuits from noisy power stage

- Testing validation confirming proper Hall sensor operation across conditions

Encoder Interface Circuits

- Differential receiver circuits (RS-422, RS-485) for incremental encoders

- Pull-up resistors and filtering for single-ended encoder outputs

- High-speed input capture (>1MHz) tracking position at maximum motor speeds

- Index pulse detection enabling absolute position reference

- Encoder supply regulation providing clean 5V power to encoder

- ESD protection on encoder inputs preventing damage from static discharge

Providing Motor Protection and Diagnostics

Motor drivers require comprehensive protection preventing damage from overcurrent (stalled rotor, overload), overvoltage (regenerative braking, supply transients), undervoltage (brownout conditions), and overtemperature (insufficient cooling, ambient extremes). Protection implementation must respond within microseconds during faults while avoiding false trips during normal transient conditions.

APTPCB implements multi-layer motor protection ensuring safe operation.

Key Protection Features

Overcurrent and Stall Detection

- Phase current monitoring detecting overcurrent conditions within microseconds

- Stall detection identifying blocked rotor or excessive load conditions

- Current limiting reducing drive voltage during sustained overload

- I²t protection integrating current over time preventing thermal damage

- Hardware overcurrent shutdown providing backup protection

- Diagnostic reporting communicating fault conditions to system controller

Temperature Monitoring

- Heat sink temperature sensing enabling thermal derating and shutdown

- Motor thermistor input monitoring winding temperatures in equipped motors

- Ambient temperature measurement compensating control parameters

- Thermal model estimation predicting semiconductor temperatures

- Progressive derating reducing current at elevated temperatures

- Overheat protection shutting down before damage occurs

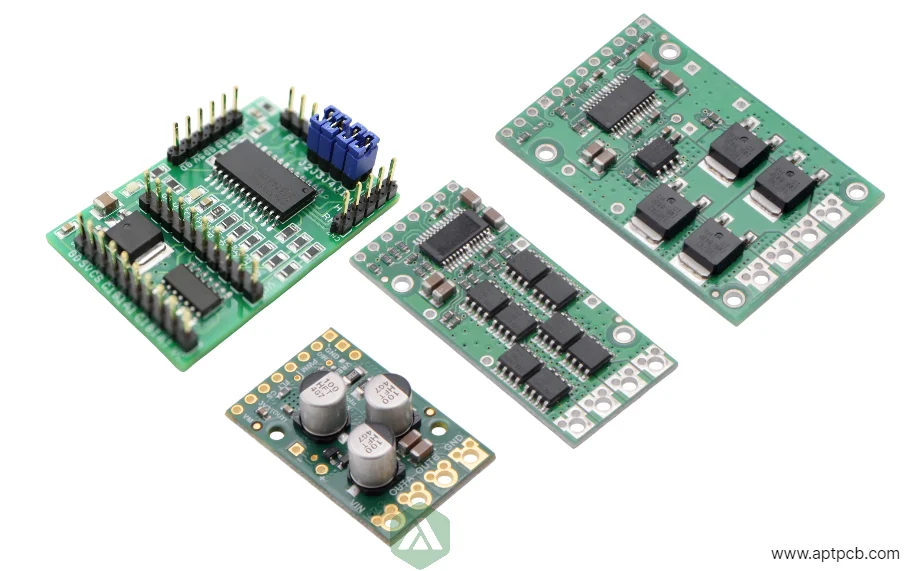

Supporting Diverse Motor Applications

Motor drivers serve applications including industrial automation (conveyors, pumps, fans), robotics (manipulators, mobile robots, drones), HVAC (compressors, blowers), consumer products (appliances, power tools), and automotive (EPS, HVAC, actuators) requiring application-specific optimizations in control algorithms, interfaces, environmental ratings, and certifications.

APTPCB provides flexible manufacturing supporting diverse motor control applications.

Key Application Requirements

Industrial Automation

- Rugged construction surviving factory environments (-40 to +70°C)

- Communication interfaces (EtherCAT, CANopen, Modbus) for factory networks

- Position and velocity control modes supporting diverse automation needs

- DIN rail or chassis mounting for industrial enclosures

- High reliability (>100,000 hour MTBF) minimizing maintenance

- Industrial certifications (CE, UL508) enabling global installations

Robotics and Consumer

- Compact size and light weight for space-constrained applications

- Battery operation supporting portable and mobile platforms

- Efficient operation maximizing runtime from limited battery capacity

- Sensorless control options reducing cost and complexity

- Safety features (safe torque off) meeting collaborative robot requirements

- Cost optimization achieving competitive consumer and robotics pricing

Through application-optimized designs and flexible manufacturing coordinated with robotics industry expertise, APTPCB enables motor driver manufacturers serving diverse motion control markets worldwide.

Enabling Control Algorithm Implementation

Modern motor drivers implement sophisticated control algorithms including six-step commutation, sinusoidal FOC (field-oriented control), sensorless control using back-EMF sensing, and advanced features like anti-cogging, acoustic noise reduction, and adaptive control. Implementation requires high-performance microcontrollers or DSPs executing control loops at 10-50kHz while interfacing with power stage, sensors, and system controller.

APTPCB supports motor control electronics with validated assembly processes.

Control Integration

Microcontroller Platform

- ARM Cortex-M4/M7 or dedicated motor control MCUs providing DSP capability

- High-resolution PWM outputs (200MHz+ timers) achieving precise commutation

- Fast ADC inputs (1-2MSPS) sampling phase currents for FOC

- Encoder input capture and Hall sensor interfaces for position feedback

- Communication peripherals (CAN, UART, SPI, I2C) for system integration

- Firmware development support enabling customer-specific control algorithms

PCB Design for Control

- Analog signal integrity maintaining measurement accuracy for current/voltage sensing

- Proper grounding separating noisy power ground from sensitive analog ground

- Decoupling and filtering preventing switching noise from corrupting measurements

- Crystal oscillator layout ensuring stable timing for control algorithms

- Debug interface access enabling development and field troubleshooting

- Manufacturing support including programming and functional test development

Delivering Cost-Effective Manufacturing

Motor driver manufacturing must balance performance, reliability, and cost meeting competitive market requirements across consumer, industrial, and automotive applications. Manufacturing optimization through automation, testing efficiency, and supply chain management enables competitive pricing while maintaining quality standards.

APTPCB delivers cost-effective motor driver manufacturing.

Manufacturing Excellence

Production Capabilities

- Automated assembly and testing maximizing throughput and consistency

- Motor load testing validating driver performance with actual motors

- Current and thermal testing confirming specifications under rated conditions

- Communication interface validation verifying encoder, Hall, and network interfaces

- Statistical process control monitoring quality trends enabling improvement

- Volume manufacturing supporting high-volume consumer and automotive programs

Through optimized manufacturing, comprehensive testing, and quality management coordinated with communication equipment standards, APTPCB enables motor driver manufacturers deploying reliable motion control solutions globally.