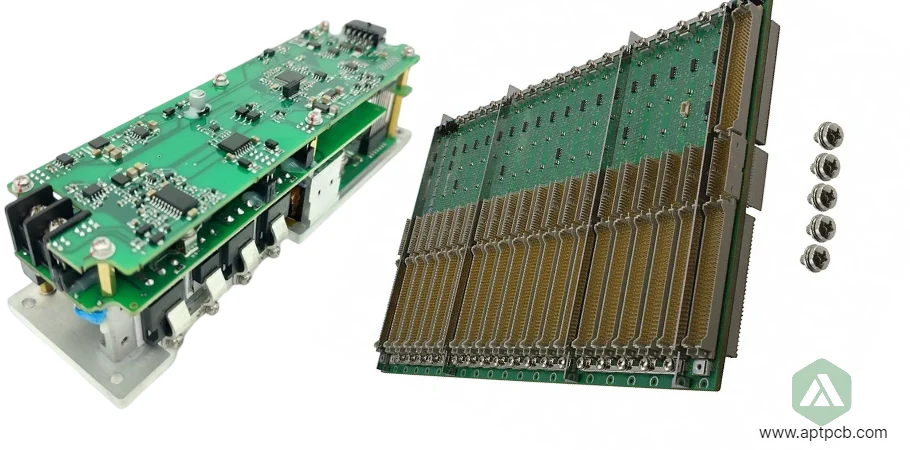

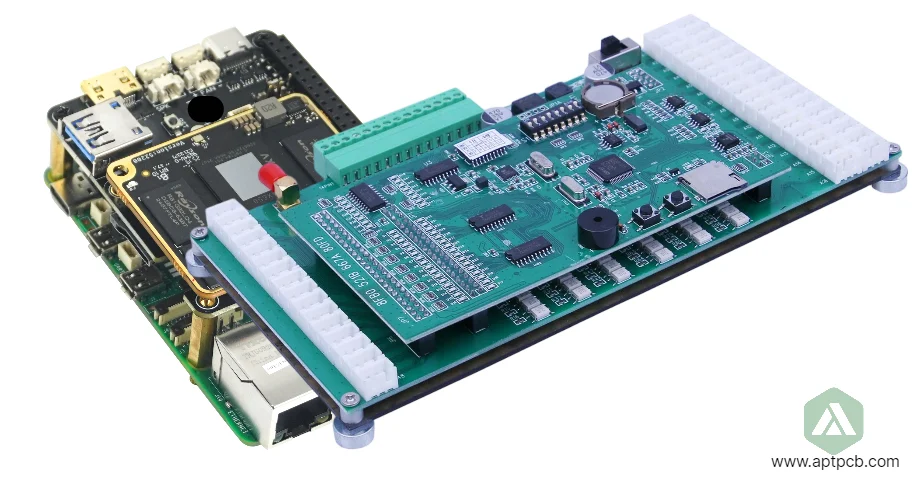

Multi-board electronic assemblies integrate multiple PCBs through backplanes, card cages, or flexible interconnects enabling modular system architectures across server platforms, telecommunications equipment, industrial control systems, and test instrumentation requiring coordinated electrical interfaces, mechanical alignment, and system-level validation ensuring reliable operation of interconnected subsystems supporting mission-critical applications through 10-15 year operational lifetimes.

At APTPCB, we deliver comprehensive multi-board assembly services managing complete system integration from individual PCB fabrication through final system test with box build assembly capabilities. Our expertise supports 2-20+ board systems across diverse architectures including backplane-based, mezzanine card, and cable-interconnected configurations with validated electrical and mechanical integration processes.

Managing Signal Integrity Across Board-to-Board Interfaces

High-speed data transmission between multiple boards presents significant signal integrity challenges as interconnect impedance discontinuities, ground bounce, and crosstalk degrade signal quality causing bit errors, reduced operating margins, and system instability. Inadequate interface design creates reflections exceeding 10% causing eye closure, timing violations failing to meet protocol specifications — directly impacting system performance and reliability in computing and telecommunications applications.

At APTPCB, our multi-board systems implement validated interconnect strategies maintaining signal integrity across board interfaces.

Key Signal Integrity Implementation Techniques

- Controlled Impedance Connectors: Precision high-speed connectors maintaining 50Ω or 100Ω differential impedance through mating interface minimizing reflections at gigabit data rates with ICT test validation ensuring proper installation.

- Backplane Design Optimization: Low-loss PCB materials (mid-loss or ultra-low-loss) in backplane construction minimizing insertion loss enabling longer trace lengths at multi-gigabit rates supporting high-density card cage architectures.

- Via Transition Management: Back-drilling or buried via structures eliminating resonant stubs improving return loss by 5-10dB at frequencies above 10GHz critical for PCIe Gen4/5 or 100G Ethernet applications.

- Power Distribution Network Design: Low-impedance power planes with distributed decoupling preventing supply voltage droop during simultaneous switching maintaining clean power across all interconnected boards.

- Ground Continuity Architecture: Multi-point grounding through backplane or direct board-to-board connections minimizing ground bounce and providing low-impedance return paths for high-frequency signals.

- Pre-compliance Testing: TDR measurements and network analysis during development validating impedance matching and insertion loss specifications before full system integration through flying probe testing capabilities.

Validated Electrical Performance

By implementing comprehensive signal integrity design practices, validated connector selection, and thorough electrical characterization supported by our manufacturing processes, APTPCB enables multi-board systems achieving error-free operation at gigabit data rates supporting high-performance computing, telecommunications, and industrial automation applications across diverse system architectures.

Ensuring Mechanical Alignment and Connector Reliability

Precise mechanical alignment between multiple boards maintains electrical connectivity through thousands of insertion-extraction cycles while preventing connector damage from misalignment, excessive forces, or thermal expansion mismatches. Inadequate mechanical design causes intermittent connections from fretting corrosion, accelerated contact wear, or complete connector failure requiring expensive field service — significantly impacting system availability and customer satisfaction in critical applications.

At APTPCB, our assembly services implement validated mechanical integration ensuring long-term connector reliability.

Key Mechanical Integration Techniques

- Card Guide and Alignment Systems: Precision-machined card guides or molded guide rails maintaining accurate board positioning during installation preventing connector misalignment and ensuring consistent insertion forces.

- Connector Mating Force Optimization: Proper connector selection and PCB support structures distributing insertion forces preventing board flexure or connector damage during installation and removal operations.

- Thermal Expansion Management: Material selection and mechanical design accommodating CTE mismatches between PCBs, chassis, and connectors preventing stress concentration causing solder joint fatigue or connector delamination.

- Vibration and Shock Isolation: Wedge locks, ejector handles, or retention hardware securing boards preventing connector separation during transportation, installation, or operational vibration.

- Contact Finish Selection: Gold plating or selective gold over nickel finishes providing long-term contact reliability despite multiple mating cycles and harsh environmental conditions.

- Insertion-Extraction Testing: Mechanical cycling validation (100-1000 cycles) during qualification ensuring connectors meet durability specifications for field-replaceable module applications through SPI inspection of solder joint quality.

Mechanical Robustness Assurance

Through precision mechanical design, validated assembly processes, and comprehensive qualification testing coordinated with our manufacturing capabilities, APTPCB delivers multi-board systems achieving reliable mechanical and electrical performance supporting field-replaceable architectures across industrial, telecommunications, and computing applications worldwide.

Coordinating System-Level Power Distribution

Multi-board systems require coordinated power distribution delivering diverse voltages (3.3V, 5V, 12V, 48V) across multiple boards while maintaining regulation, managing transient loads, and providing protection preventing single-board faults from affecting entire system operation. Inadequate power architecture design causes voltage droop during load transients affecting system stability, insufficient current capacity limiting performance, or fault propagation creating cascading failures — directly impacting system reliability and operational availability.

At APTPCB, our system integration implements validated power distribution architectures supporting reliable multi-board operation.

Key Power Distribution Techniques

- Centralized vs Distributed Architecture: Strategic placement of power supplies and voltage regulators optimizing efficiency, load regulation, and fault isolation based on specific application requirements.

- Point-of-Load Regulation: Distributed DC-DC converters on each board providing tight voltage regulation despite backplane voltage drops improving noise immunity and transient response.

- Current Sharing and Redundancy: Parallel power supplies with active current sharing ensuring balanced loading and N+1 redundancy maintaining operation despite single supply failure.

- Inrush Current Management: Sequenced power-up across multiple boards preventing excessive transient currents causing voltage sag or nuisance trips of upstream protection devices.

- Power Monitoring and Protection: Distributed current and voltage monitoring enabling rapid fault detection isolating failed boards preventing damage propagation through system.

- Validation Testing: Full-load system testing measuring voltage regulation, ripple, and transient response across all boards confirming power distribution specifications through communication equipment standards compliance.

Robust Power System Implementation

By implementing comprehensive power distribution design, validated component selection, and system-level testing protocols supported by our quality processes, APTPCB enables multi-board systems achieving stable power delivery supporting reliable high-performance operation across computing, industrial control, and telecommunications infrastructure applications.

Executing Comprehensive System-Level Validation

Multi-board assemblies require testing beyond individual PCB validation verifying board-to-board communication, system boot-up sequences, thermal interaction between boards, and mechanical installation procedures ensuring complete system functionality before deployment. Inadequate system testing causes field failures from interface timing issues, thermal management problems, or configuration errors requiring expensive on-site troubleshooting — significantly increasing total cost of ownership and damaging manufacturer reputation.

At APTPCB, our assembly services provide comprehensive system-level testing validating complete multi-board functionality.

System Validation Techniques

- Functional System Testing: Complete system boot and operational testing verifying all boards communicate properly and system meets functional specifications across all operating modes.

- Thermal System Analysis: Thermal imaging and embedded sensor monitoring validating temperatures across all boards remain within specifications during sustained full-load operation.

- Communication Protocol Validation: Bus analyzer testing verifying inter-board protocols (PCIe, Ethernet, USB) meet timing and electrical specifications preventing intermittent communication failures.

- Power Sequencing Verification: Validation of power-up and power-down sequences ensuring proper ordering preventing latch-up conditions or configuration errors.

- Environmental Testing: System-level temperature, humidity, and vibration testing validating mechanical assemblies and electrical connections survive operational environmental conditions.

- Burn-In and Reliability Testing: Extended system operation under stress conditions identifying early failures through drone UAV quality standards application enabling high-reliability deployments.

Validated System Performance

Through comprehensive system-level test protocols, validated test equipment, and experienced test engineering supported by our quality management systems, APTPCB delivers multi-board assemblies meeting functional specifications, environmental requirements, and reliability targets supporting successful deployment across mission-critical computing, telecommunications, and industrial applications worldwide.

Enabling Modular and Field-Serviceable Architectures

Modular multi-board designs enable cost-effective capacity scaling, simplified inventory management, and reduced downtime through field-replaceable modules supporting telecommunications equipment, computing servers, and industrial control systems requiring high availability and operational flexibility. Modular architecture implementation must balance standardization enabling interchangeability against customization supporting diverse application requirements.

At APTPCB, we support modular system development through flexible manufacturing and comprehensive documentation.

Modular System Support

Design for Modularity

- Standardized mechanical interfaces enabling board interchangeability across product variants reducing inventory complexity and simplifying field service operations.

- Well-defined electrical interfaces (pinouts, protocols, power requirements) enabling module substitution without system redesign supporting long product lifecycles.

- Automated configuration detection enabling plug-and-play operation without manual setup reducing installation time and preventing configuration errors.

- Backward compatibility management maintaining interface specifications across product generations supporting gradual system upgrades without complete replacement.

Manufacturing and Lifecycle Support

- Flexible manufacturing accommodating diverse module configurations and volumes from prototype through production quantities supporting varied customer requirements.

- Comprehensive documentation including assembly drawings, test procedures, and service manuals supporting field installation and maintenance operations.

- Spare parts management and long-term availability commitments ensuring modules remain available throughout 10-15 year product lifecycles through robotics industry best practices.

- Revision control and traceability enabling identification of specific module versions supporting failure analysis and upgrade planning.

Through modular design support, flexible manufacturing capabilities, and comprehensive lifecycle management coordinated with our assembly services, APTPCB enables multi-board system manufacturers deploying field-serviceable architectures supporting high-availability telecommunications, computing, and industrial applications across global markets.